Rare Earth Plate Magnet

Wide Variety of Chute Applications

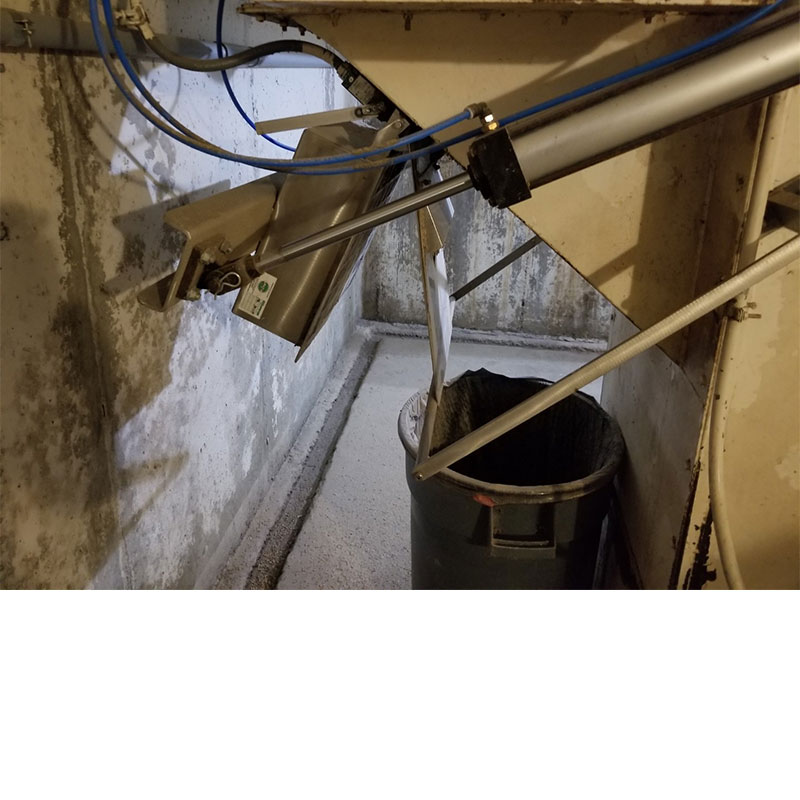

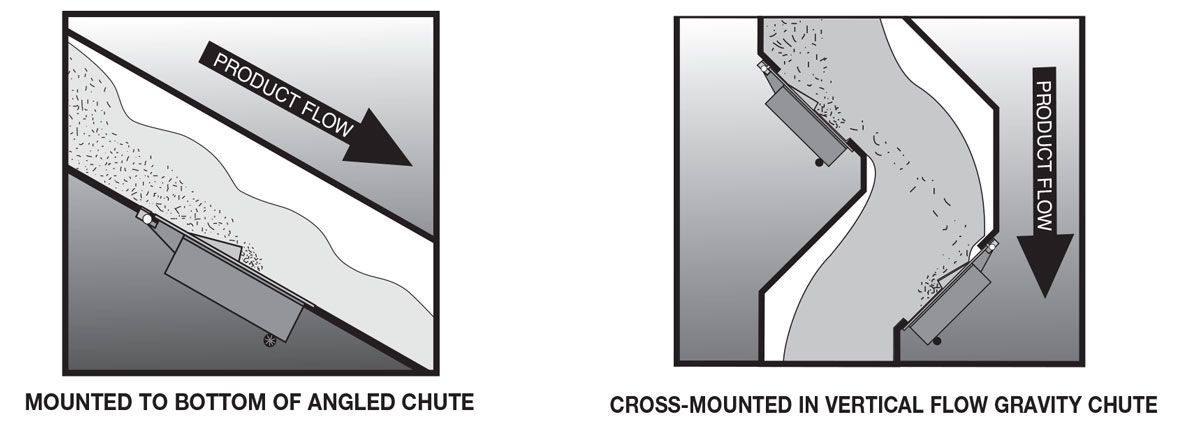

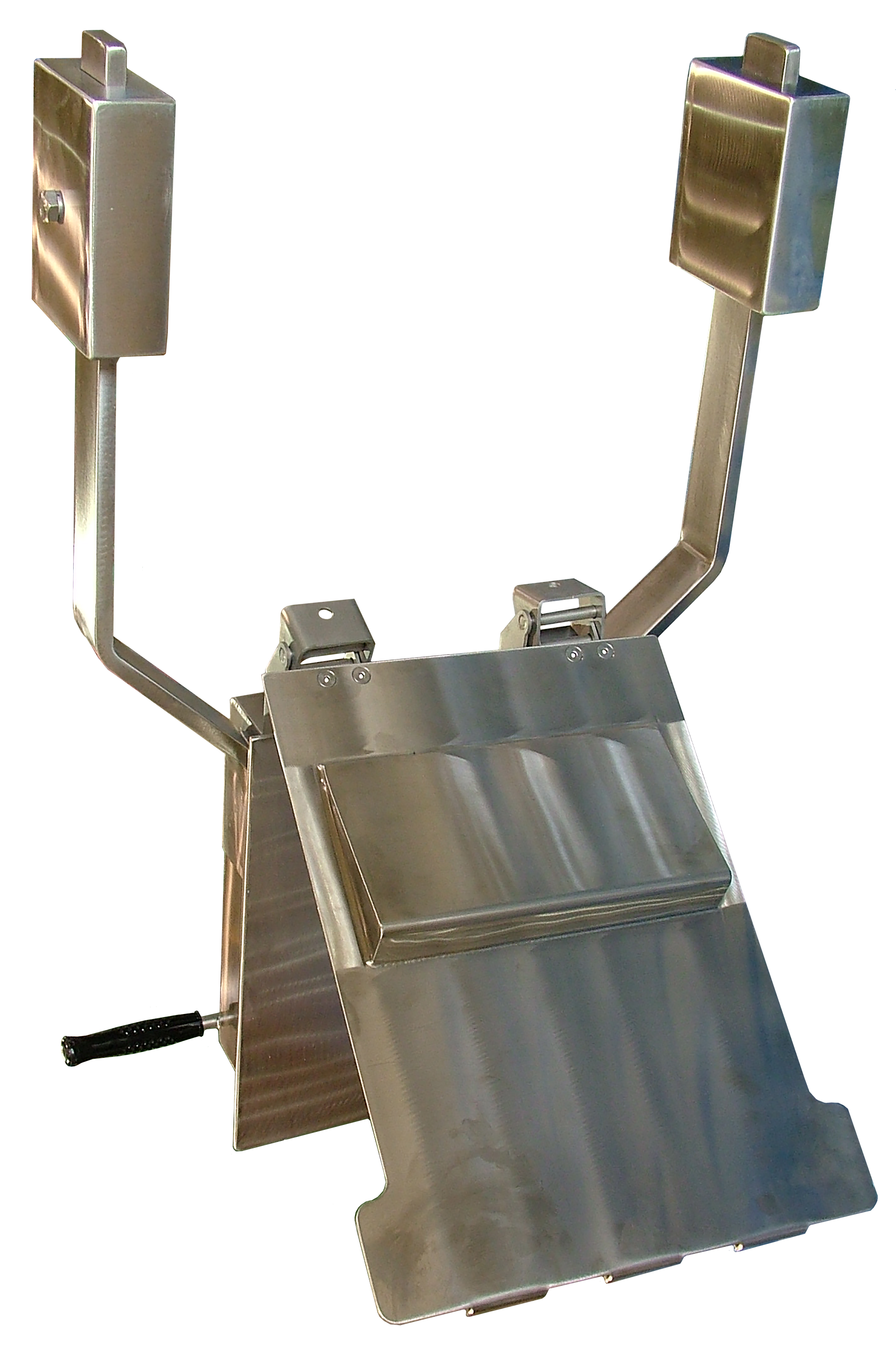

MPI’s Rare Earth Plate Magnets are designed for use in gravity-fed angled chutes up to 60 degrees, which convey low to high volume product streams. Typical installations are below-the-flow, where product flows over the magnetic face, providing optimum ferrous tramp metal retention in a wide variety of chute applications.

Benefits of the Rare Earth Plate Magnet From Magnetic Products, Inc

- 100% Stainless steel enclosed design

- Permanent magnet material – will not demagnetize

- Maximum separation magnetic circuit

- 1” wide uniform sealing flange to prevent product leakage

- Waterproof, weather-resistant enclosure

- Rugged all-welded construction

Rare Earth Plate Magnet Product Details

How It Works

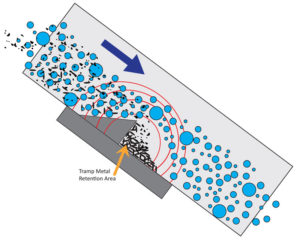

MPI’s Single Step and Double Step Ceramic Plate Magnets are designed to divert the product stream away from the magnet surface while allowing tramp metal to be magnetically attracted to the magnet’s surface behind the collection steps. Magnetic 400 series stainless steel pole areas maximize the holding power of the magnets. These Plate Magnets are easily installed and are supplied complete with sanitary hinges, latches, and mounting hardware. The hinged mounting design permits quick, easy cleaning of the magnet surface. The strong magnetic field is effective in product streams up to 8” deep.

MPI’s Single Step and Double Step Ceramic Plate Magnets are designed to divert the product stream away from the magnet surface while allowing tramp metal to be magnetically attracted to the magnet’s surface behind the collection steps. Magnetic 400 series stainless steel pole areas maximize the holding power of the magnets. These Plate Magnets are easily installed and are supplied complete with sanitary hinges, latches, and mounting hardware. The hinged mounting design permits quick, easy cleaning of the magnet surface. The strong magnetic field is effective in product streams up to 8” deep.

Product Options

| Powerful Rare Earth magnet material | |

| Quick-clean designs available | |

| Self-Clean designs available |  |

| Replaceable abrasive resistant faceplates |  |

| USDA finish |  |

Specifications

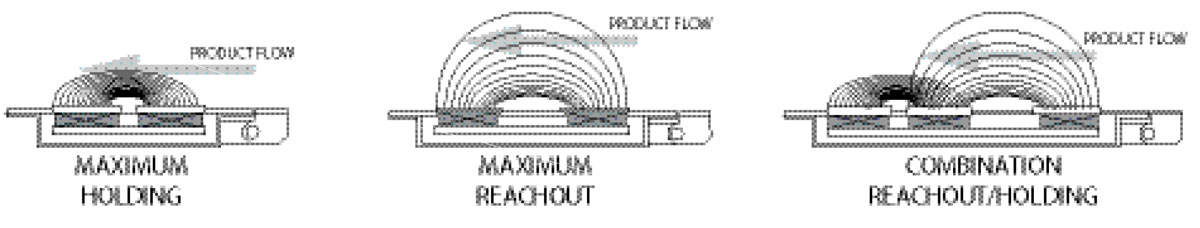

Magnetic Polarity For:

US Customary Units

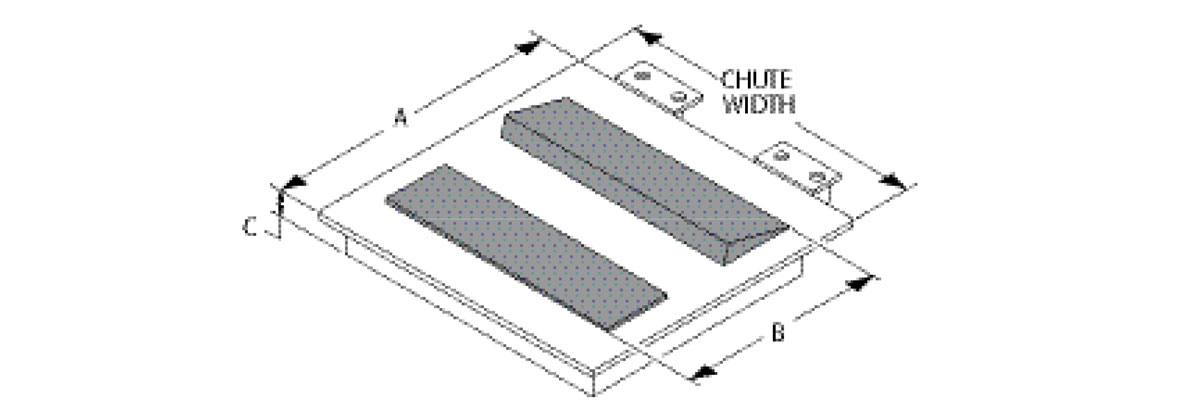

| Magnet Series | NP Model | Single Step Model | Double Step Model | Triple Step Model | Overall Length (A) | Magnetic Face Length (B) |

Thickness (C) |

Effecting Magnetic Field Depth |

Approx. Weight | |||

| IN | IN | IN | IN | LB | ||||||||

| 100- Holding |

NP-H110 | NP-H110-SS | NP-H110-DS | N/A | 8.0 | 6.0 | 1.25 | 2.0 | 14 | |||

| 100-Reachout |

NP-R110 | NP-R110-SS | NP-R110-DS | N/A | 10.0 | 8.0 | 1.25 | 4.0 | 14 | |||

| 200-Holding | NP-H210 | NP-H210-SS | NP-H210-DS | N/A | 8.0 | 6.0 | 2.25 | 3.0 | 30 | |||

| 200-Reachout | NP-R210 | NP-R210-SS | NP-R210-DS | N/A | 10.0 | 8.0 | 2.25 | 5.0 | 30 | |||

| 300-Holding | NP-H310 | NP-H310-SS | NP-H310-DS | NP-H310-TS | 10.0 | 8.0 | 1.25 | 2.0 | 55 | |||

| 300-Reachout | NP-R310 | NP-R310-SS | NP-R310-DS | NP-R310-TS | 14.0 | 12.0 | 1.25 | 4.0 | 55 | |||

| 300-Combination | NP-C310 | NP-C310-SS | NP-C310-DS | NP-C310-TS | 12.5 | 10.5 | 1.25 | 4.0 | 55 | |||

| 400-Holding | NP-H410 | NP-H410-SS | NP-H410-DS | NP-H410-TS | 10.0 | 8.0 | 2.25 | 3.0 | 90 | |||

| 400-Reachout | NP-R410 | NP-R410-SS | NP-R410-DS | NP-R410-TS | 14.0 | 12.0 | 2.25 | 5.0 | 90 | |||

| 400-Combination | NP-C410 | NP-C410-SS | NP-C410-DS | NP-C410-TS | 12.5 | 10.5 | 2.25 | 5.0 | 90 | |||

Metric Units

| Magnet Series | NP Model | Single Step Model | Double Step Model | Triple Step Model | Overall Length (A) | Magnetic Face Length (B) |

Thickness (C) |

Effecting Magnetic Field Depth |

Approx. Weight | |||

| MM | MM | MM | MM | KG | ||||||||

| 100- Holding |

NP-H110 | NP-H110-SS | NP-H110-DS | N/A | 203.2 | 152.4 | 31.75 | 50.8 | 6.3 | |||

| 100-Reachout |

NP-R110 | NP-R110-SS | NP-R110-DS | N/A | 254.0 | 203.2 | 31.75 | 101.6 | 6.3 | |||

| 200-Holding | NP-H210 | NP-H210-SS | NP-H210-DS | N/A | 203.2 | 152.4 | 57.15 | 76.2 | 16.6 | |||

| 200-Reachout | NP-R210 | NP-R210-SS | NP-R210-DS | N/A | 254.0 | 203.2 | 57.15 | 127.0 | 13.6 | |||

| 300-Holding | NP-H310 | NP-H310-SS | NP-H310-DS | NP-H310-TS | 254.0 | 203.2 | 31.75 | 50.8 | 24.9 | |||

| 300-Reachout | NP-R310 | NP-R310-SS | NP-R310-DS | NP-R310-TS | 355.6 | 304.8 | 31.75 | 101.6 | 24.9 | |||

| 300-Combination | NP-C310 | NP-C310-SS | NP-C310-DS | NP-C310-TS | 304.8 | 254.0 | 31.75 | 101.6 | 24.9 | |||

| 400-Holding | NP-H410 | NP-H410-SS | NP-H410-DS | NP-H410-TS | 254.0 | 203.2 | 57.15 | 76.2 | 40.8 | |||

| 400-Reachout | NP-R410 | NP-R410-SS | NP-R410-DS | NP-R410-TS | 355.6 | 304.8 | 57.15 | 127.0 | 40.8 | |||

| 400-Combination | NP-C410 | NP-C410-SS | NP-C410-DS | NP-C410-TS | 304.8 | 254.0 | 57.15 | 127.0 | 40.8 | |||