Plate Liquid Trap Magnet

Protect Liquid and Slurry Lines

MPI’s Trap Magnet — Plate Design — is designed to protect liquid and slurry lines and pumps by magnetically removing ferrous contaminants from liquid and slurry product streams. LPT Series Trap Magnets provide purification of liquids and tramp metal separation for a variety of wet food processing industries, from fluid and strained products to viscous and heavy fibrous products.

Benefits of the Plate Liquid Trap Magnet From Magnetic Products, Inc

- Type 304 stainless steel sanitary design and liquid-tight construction

- Quick-release tri-clover clamp for easy inspection and cleaning

- For use in product streams up to 75 psi

- Available for line sizes from 1 ½ ” to 3” dia. in ¼” increments

Plate Liquid Trap Magnet Product Details

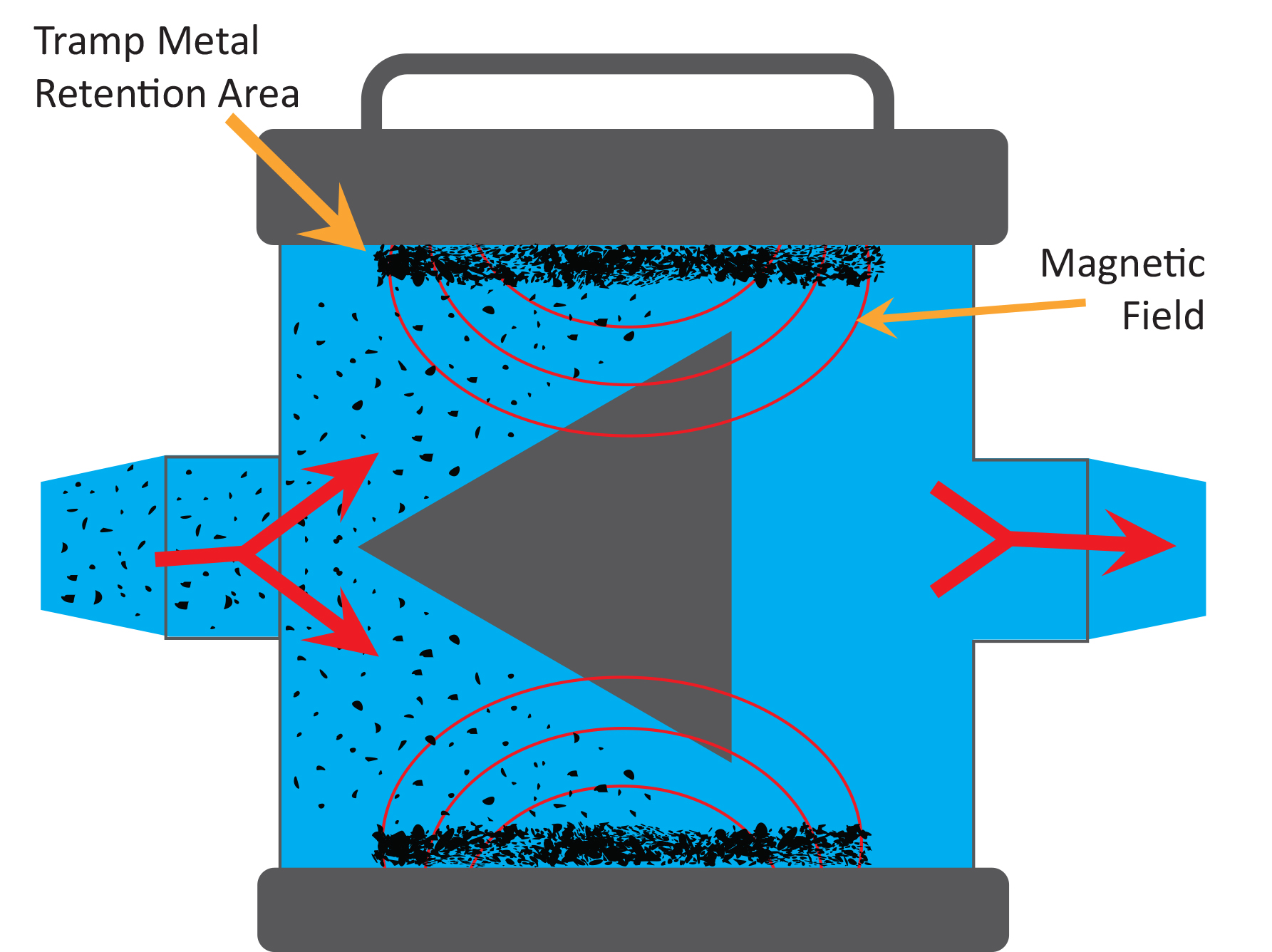

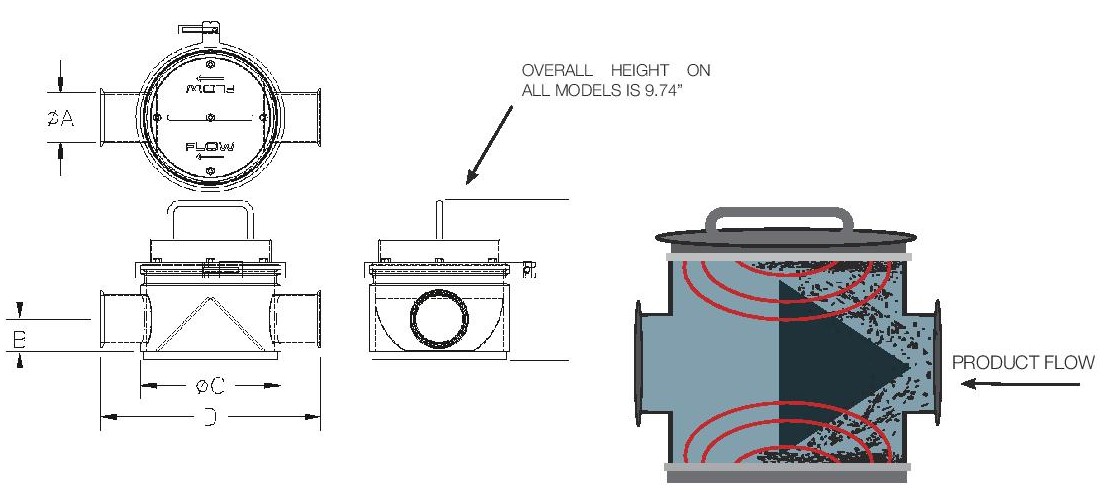

How It Works

Liquid Trap Magnet — Plate Design

Liquid Trap Magnet — Plate Design

A baffle within the trap line directs the product flow toward the magnetic field, assuring that ferrous contaminants come into contact with the powerful magnet. The area within the trap is enlarged to slow the product stream and allow increased exposure to the entire magnetic surface. The suggested placement of the trap is in horizontal lines, with the magnet element facing “up” to simplify cleaning. After product flow is terminated, the magnet is easily cleaned by removing the tri-clover clamp, lifting the magnetic element and hand-cleaning the surface.

Product Options

- Other line connection types available: bevel seat, pipe thread, or weld ends

- 316 stainless steel

- USDA model available

Specifications

US Customary Units

| LPT Model # | Inlet Pipe Diameter (A) | Centerline Height (B) |

Unit Diameter (C) | Total Width (D) | Unit Weight |

| IN | IN | IN | IN | LBS | |

| LPT-15 | 1.5 | 2.0 | 7.78 | 11.5 | 17 |

| LPT-20 | 2.0 | 2.0 | 7.78 | 11.5 | 17 |

| LPT-25 | 2.5 | 2.0 | 7.78 | 13.5 | 30 |

| LPT-30 | 3.0 | 2.0 | 7.78 | 13.5 | 30 |

| CAPACITIES IN GALLONS/MINUTE | ||||

| LPT Trap Size | PRODUCT CLASSIFICATION | |||

| FLUID & STRAINED | FIBROUS & CRUSHED | VISCOUS or HEAVY | VISCOUS & FIBROUS | |

| IN | GPM | GPM | GPM | GPM |

| 1.5 | 65 | 50 | 25 | 15 |

| 2.0 | 65 | 50 | 25 | 15 |

| 2.5 | 140 | 90 | 60 | 35 |

| 3.0 | 140 | 90 | 60 | 35 |

Metric Units

| LPT Model # | Inlet Pipe Diameter (A) | Centerline Height (B) |

Unit Diameter (C) | Total Width (D) | Unit Weight |

| MM | MM | MM | MM | KGS | |

| LPT-15 | 38 | 51 | 198 | 292 | 8 |

| LPT-20 | 51 | 51 | 198 | 292 | 8 |

| LPT-25 | 64 | 51 | 198 | 343 | 14 |

| LPT-30 | 76 | 51 | 198 | 343 | 14 |

| CAPACITIES IN LITERS/MINUTE | ||||

| LPT Trap Size | PRODUCT CLASSIFICATION | |||

| FLUID & STRAINED | FIBROUS & CRUSHED | VISCOUS or HEAVY | VISCOUS & FIBROUS | |

| MM | LPM | LPM | LPM | LPM |

| 38 | 245 | 189 | 94 | 57 |

| 51 | 245 | 189 | 94 | 57 |

| 64 | 528 | 339 | 226 | 132 |

| 76 | 528 | 339 | 226 | 132 |