Separation Roll

Continuous, 24/7 Automatic Removal of Tramp Iron

MPI’s Magnetic Head Pulley Separation Roll Magnets are designed to remove both large and small ferrous tramp iron contaminants from product streams in belt conveyor systems. SR-series separators provide a continuous, 24/7 automatic removal of tramp iron from the material’s flow.

Benefits of the Separation Roll From Magnetic Products, Inc

- Powerful Ceramic 8 permanent magnet material

- Stainless steel face

- Rugged, all-welded construction

- 3 different magnetic circuits available

- Face widths from 8” – 62”

- Roll diameters from 4” – 36”

Separation Roll Product Details

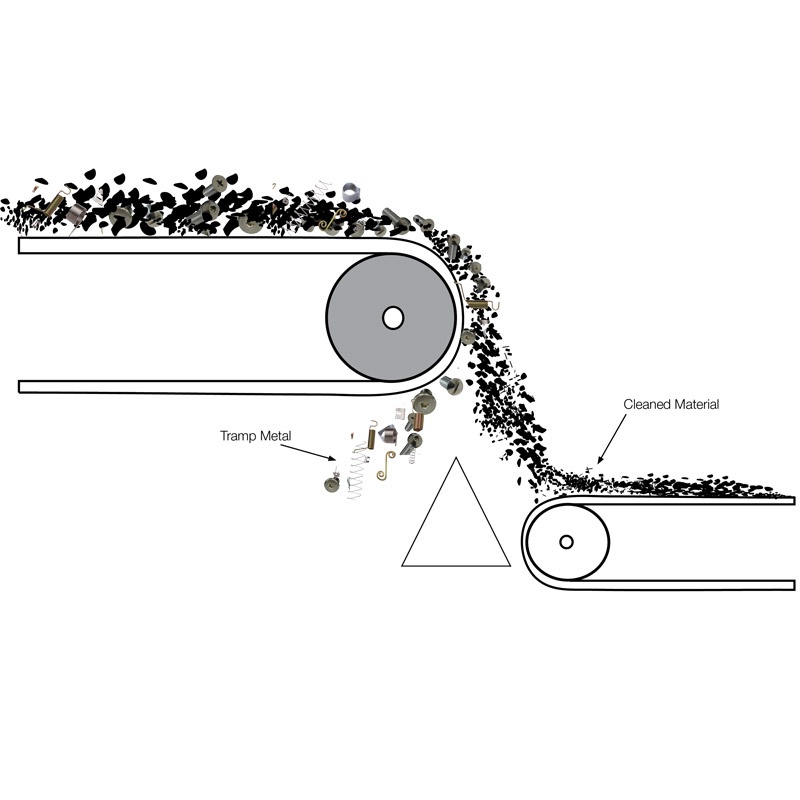

How It Works

SR separators are typically used as head pulleys in belt conveyors. As tramp metal nears the separator’s magnetic field, it is attracted and held to the conveyor’s belt until it reaches the underside of the conveyor, where it passes out of the magnetic field and discharges into a chute or bin. The cleaned, contaminant-free material discharges from the top of the conveyor, away from the tramp metal.

Product Options

- High energy Rare Earth magnetic material

- 4 crowned face styles available

- 2 hub styles available

- Carbon or stainless steel shaft

Specifications

Magnet Circuits:

Axial (A)

This magnet circuit provides alternating north and south magnetic poles around the roll diameter, providing optimum magnetic field “reach-out” and a consistent magnetic pole across the roll width. This magnet design is ideal for capturing medium to larger types of tramp metal in moderate to deep product flows on the conveyer belt.

Salient (S)

This magnet circuit provides a large number of highly concentrated magnetic poles at intervals across the roll width and a consistent magnetic pole around the roll diameter. This magnet design is ideal for capturing small to fine types of tramp metal in shallow product flows on the conveyer belt.

Radial (R)

This magnet circuit provides a lower number of highly concentrated magnetic poles at intervals across the roll width as compared to a SALIENT design, improving magnetic field “reach-out” and a consistent magnetic pole around the roll diameter. This magnet design is ideal for capturing small to larger types of tramp metal in shallow to moderate flows on the conveyer belt.

Magnet Face Options:

Flat Stainless Steel (FS)

This is the most economical option offered and provides a durable non-magnetic stainless steel belt running surface.

Flat Stainless Steel with Centering Track Bar (FSTB)

This is an economical way to provide a degree of center belt tracking, without the expensive costs of crowning.

Crowned Stainless Steel (CS)

This is the most expensive option and offers a durable non-magnetic stainless steel-belt running surface with a belt centering crown.

Crowned Vulcanized Rubber (CVR)

This option offers both an economical way to provide a belt-centering crown design and improved belt traction.

Crowned Vulcanized and Lagged Rubber (CVRL)

This option can be added to any vulcanized rubber roll where belt traction is critical. It is available in a variety of standard patterns, such as herringbone, diamond, etc.