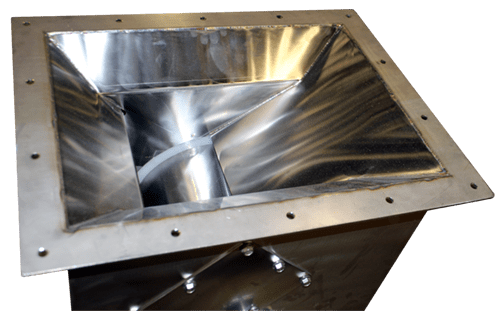

Magnetic Drum Separator and Housing

Trouble-Free Automatic Extraction of Tramp Iron

MPI’s Magnetic Drum Separator and Housing is designed to provide trouble-free automatic extraction of tramp iron from heavy flows of large size and abrasive materials such as coal, aggregates, ores, sugarcane, wheat etc. When the product stream enters the drum magnet, the powerful permanent magnetic field reaches out and retains ferrous particles on the revolving shell.

Benefits of the Magnetic Drum Separator and Housing From Magnetic Products, Inc

- Industry Leading Magnetic Performance:

- High performance Hi-G rare earth neodymium magnetic circuit generates 5400 gauss on the surface of the drum resulting in the highest separation rates (optional)

- High Separation Rates:

- 220 Degrees of magnet material around the surface of the drum increases magnetic field exposure for better separation rates and less good product carry over

- Oversized drivetrain for exponential service factor for reliable long term performance

- Minimize Carryover:

- Adjustable pant leg distribution system for fine tuning the drum separator to minimize carryover

- Adjustable Flow Rate:

- Adjustable feed gate for fine tuning feed into the system to optimize magnetic separation for flow rates

- Hassle Free Maintenance:

- Inspection doors for easy access into the drum for maintenance

- Easy removal of drum from drive side access panel for service and maintenance without removing housing from line (required for abrasive products shell replacement)

- Reinforced Seals:

- Fully sealed design features double sealed bearings with external shield and sealed magnetic drum design to prevent damage from product ingress

- Flexible Positioning:

- Adjustable magnetic arc position for fine tuning drum performance

- Made in the USA:

- American manufacturing

Magnetic Drum Separator and Housing Product Details

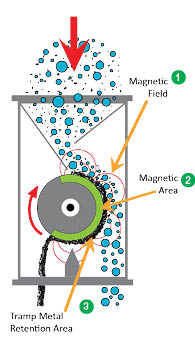

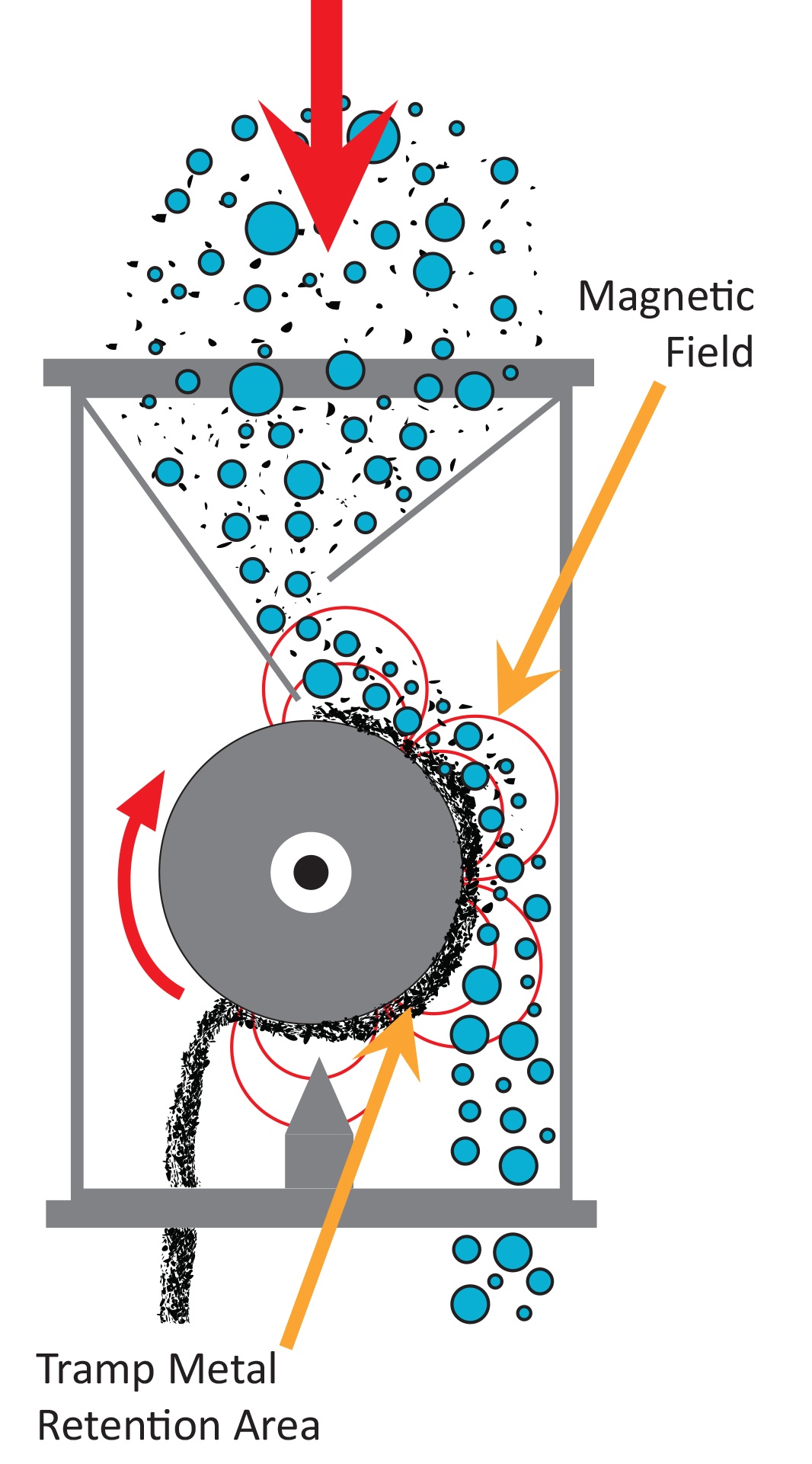

How It Works

When the product stream enters the drum magnet, the powerful permanent magnetic field reaches out and retains ferrous particles on the revolving shell. As the product stream flows by the shell, any non-ferrous product falls unhindered from the shell, while tramp iron particles are solidly retained and carried away from the product stream, out of the magnetic field, past a divider and deposited into a tramp metal collection container. These DSH-Series magnets are available in standard diameters

When the product stream enters the drum magnet, the powerful permanent magnetic field reaches out and retains ferrous particles on the revolving shell. As the product stream flows by the shell, any non-ferrous product falls unhindered from the shell, while tramp iron particles are solidly retained and carried away from the product stream, out of the magnetic field, past a divider and deposited into a tramp metal collection container. These DSH-Series magnets are available in standard diameters

Product Options

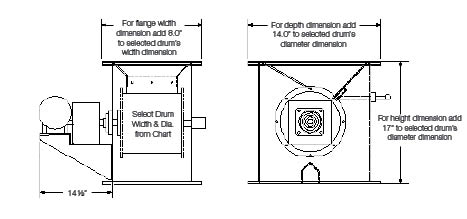

- Drum Diameter: Available diameters are 12”, 15” 18”, 24”, 30” and 36”

- Drum Width: Sizes available from 12” to 60” wide in 2” increments

- Housing:

- Drum and shaft only

- Drum with 304 stainless steel housing (Standard)

- Magnetic Circuit Design:

- Axial pole ceramic magnet (400° @ 3.5 MGO) measuring 1200 gauss on surface of drum for large and medium target tramp metal

- Axial pole rare earth magnet (176 F @ 52-55 MGOe) measuring 3300 gauss on surface of the drum

- Axial pole rare earth magnet (176 F @ 52-55 MGOe) measuring 5400 gauss on surface of the drum

- Checkerboard pole, agitator design, with rare earth magnet (176 F @ 52-55 MGOe) for highly commingled materials

- Shell Material:

- 12 gauge stainless steel (Standard)

- 7 gauge manganese for high abrasion and large tramp metal applications. Extra shell thickness reduces gauss on surface of drum. Also includes manganese wipers, diverter and inlet.

- Drum Wipers:

- Single drum wiper for applications with low ferrous metal content and reduced product carryover

- 3 evenly spaces wipers for applications with medium to high ferrous metal content (Standard)

- Drive Design:

- Chain drive with torque limiter at fixed RPM

- Chain drive with torque limiter XP motor at fixed RPM

- Chain drive with torque limiter and VFD for adjustable RPM for fine tuning system

- Input Voltage:

- 230/460 Volts, 3 Phase, 60 Hz (Standard)

- 575 Volts, 3 Phase, 60 Hz for Canada

Specifications

US Customary Units

| Drum Diameter (Inches) | Drum Width | Capacity |

| IN | FT³/HR | |

12″ Drum 45 RPM |

12 | 1000 |

| 14 | 1200 | |

| 16 | 1400 | |

| 18 | 1600 | |

| 20 | 1800 | |

| 24 | 2200 | |

| 30 | 2800 | |

| 36 | 3300 | |

| 42 | 3900 | |

15″ Drum 40 RPM |

12 | 1250 |

| 14 | 1500 | |

| 16 | 1750 | |

| 18 | 2000 | |

| 20 | 2200 | |

| 24 | 2700 | |

| 30 | 3400 | |

| 36 | 4100 | |

| 42 | 4800 | |

| 48 | 5500 | |

18″ Drum 35 RPM |

12 | 1600 |

| 14 | 1900 | |

| 16 | 2200 | |

| 18 | 2500 | |

| 20 | 2800 | |

| 24 | 3400 | |

| 30 | 4300 | |

| 36 | 5200 | |

| 42 | 6100 | |

| 48 | 7000 | |

24″ Drum 30 RPM |

18 | 3700 |

| 20 | 4200 | |

| 24 | 5100 | |

| 30 | 6500 | |

| 36 | 7800 | |

| 42 | 9200 | |

| 48 | 10500 | |

| 54 | 11900 | |

| 60 | 13200 | |

30″ Drum 25 RPM |

24 | 7200 |

| 30 | 9200 | |

| 36 | 11100 | |

| 42 | 13000 | |

| 48 | 14900 | |

| 54 | 16800 | |

| 60 | 18700 | |

36″ Drum 20 RPM |

24 | 9800 |

| 30 | 12500 | |

| 36 | 15200 | |

| 42 | 17800 | |

| 48 | 20400 | |

| 54 | 23000 | |

| 60 | 25600 |

Metric Units

Drum Diameter (Inches) |

Drum Width | Capacity |

| MM | M³/HR | |

12″ Drum 45 RPM |

305 | 28 |

| 356 | 34 | |

| 406 | 40 | |

| 457 | 45 | |

| 508 | 50 | |

| 610 | 62 | |

| 762 | 80 | |

| 915 | 93 | |

| 1067 | 110 | |

15″ Drum 40 RPM |

305 | 35 |

| 356 | 42 | |

| 406 | 50 | |

| 457 | 57 | |

| 508 | 62 | |

| 610 | 76 | |

| 762 | 96 | |

| 915 | 116 | |

| 1067 | 136 | |

| 1219 | 156 | |

18″ Drum 35 RPM |

305 | 45 |

| 356 | 54 | |

| 406 | 62 | |

| 457 | 71 | |

| 508 | 79 | |

| 610 | 96 | |

| 762 | 122 | |

| 915 | 147 | |

| 1067 | 173 | |

| 1219 | 198 | |

24″ Drum 30 RPM |

457 | 105 |

| 508 | 119 | |

| 610 | 145 | |

| 762 | 185 | |

| 915 | 220 | |

| 1067 | 260 | |

| 1219 | 300 | |

| 1372 | 340 | |

| 1524 | 375 | |

30″ Drum 25 RPM |

610 | 205 |

| 762 | 260 | |

| 915 | 315 | |

| 1067 | 370 | |

| 1219 | 420 | |

| 1372 | 475 | |

| 1524 | 530 | |

36″ Drum 20 RPM |

610 | 280 |

| 762 | 350 | |

| 915 | 430 | |

| 1067 | 500 | |

| 1219 | 580 | |

| 1372 | 650 | |

| 1524 | 725 |