Magnetic Belt Feeder

High-Intensity Rare Earth Magnetic Design

Magnetic Belt Feeders are designed for applications where weakly ferrous material, such as stainless steel or embedded contamination, need to automatically be removed from a product stream. The system uses a high-intensity rare earth magnetic design that increases the gauss on the surface of the belt compared to a magnetic head pulley design.

Benefits of the Magnetic Belt Feeder From Magnetic Products, Inc

- Standard belt widths from 10” to 60”

- Ultra thin belt designs to reduce airgap, increases magnetic performance on the surface of the belt

- Adjustable splitter gate to fine tune separation

- Optional feeders available to ensure full product distribution across the belt, optimizing separation rates

Magnetic Belt Feeder Product Details

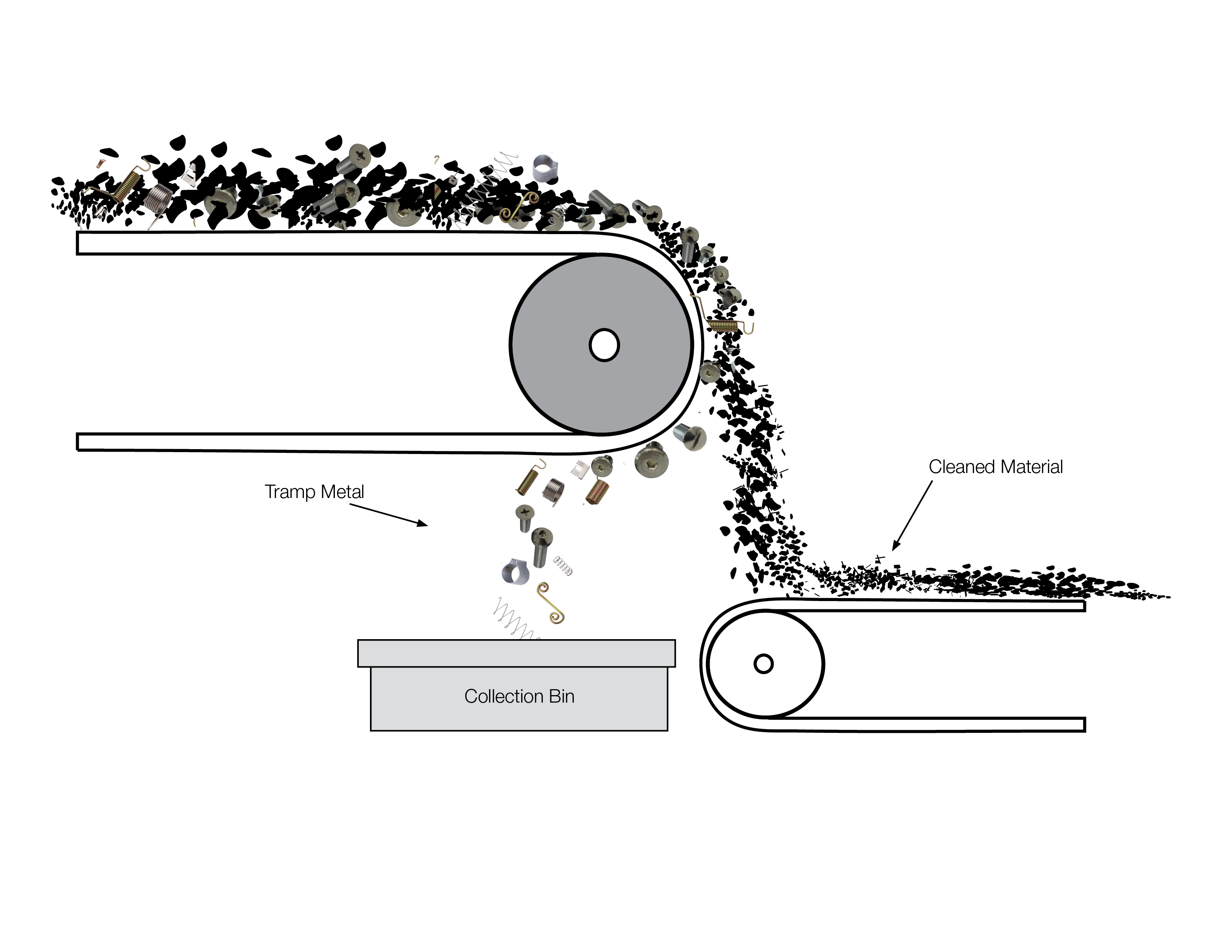

How It Works

Magnetic Belt Feeders

As the product reaches the end of the feeder’s conveyor, it passes through a magnetic field. Gravity causes clean, non-ferrous materials to exit and fall away from the MBF system. Ferrous metals are carried around the head pulley and are transported away from the magnetic field where they fall from the conveyor belt typically into a metal collections area.

Product Options

- Custom motor voltages, belt speed, delivery/discharge transitions

- Ceramic or rare earth magnet material

- Welded or bolt-on legs

- Magnetic roll circuitry: Axial, Radial

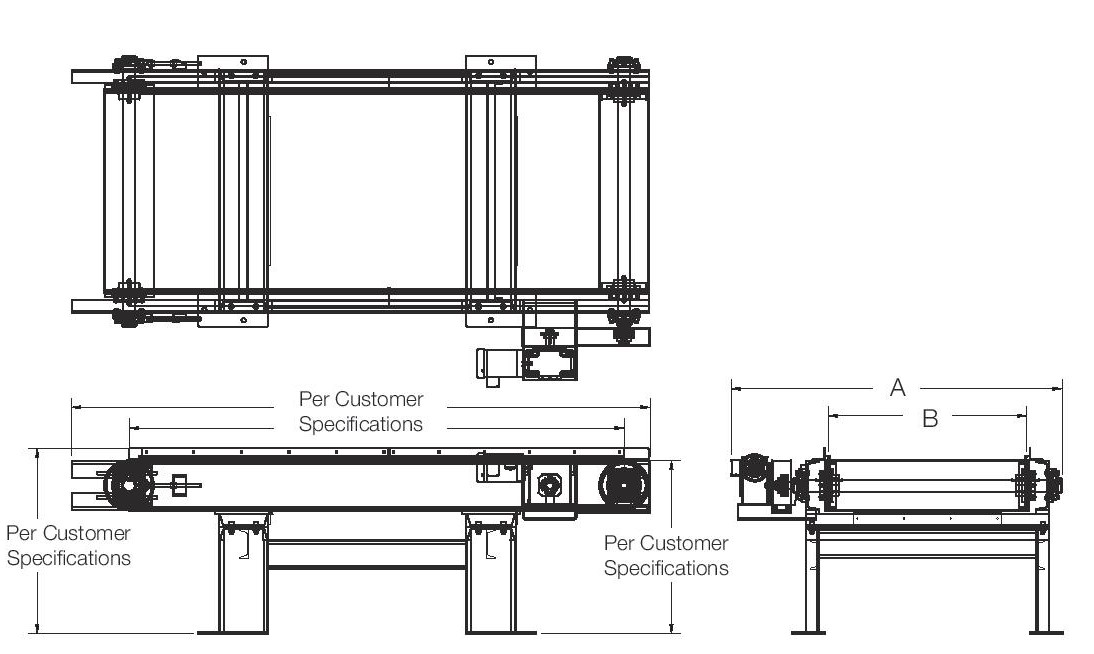

Specifications

US Customary Units

| Model # | Unit Width (A) |

Belt Width (B) |

Magnetic Roll Diameter |

| IN | IN | IN | |

| MBF-1220 | 52.20 | 20 | 12 |

| MBF-1230 | 62.20 | 30 | 12 |

| MBF-1248 | 80.20 | 48 | 12 |

Metric Units

| Model # | Unit Width (A) |

Belt Width (B) |

Magnetic Roll Diameter |

| MM | MM | MM | |

| MBF-1220 | 133 | 51 | 30 |

| MBF-1230 | 158 | 76 | 30 |

| MBF-1248 | 204 | 122 | 30 |

Related Resources

- Video - Magnetic and Metal Detector Sorting System Magnetic and Metal Detector Sorting System

- Warranty