Magnetic Rails and Pulleys

Easy Installation Into New or Existing Belted Conveyors

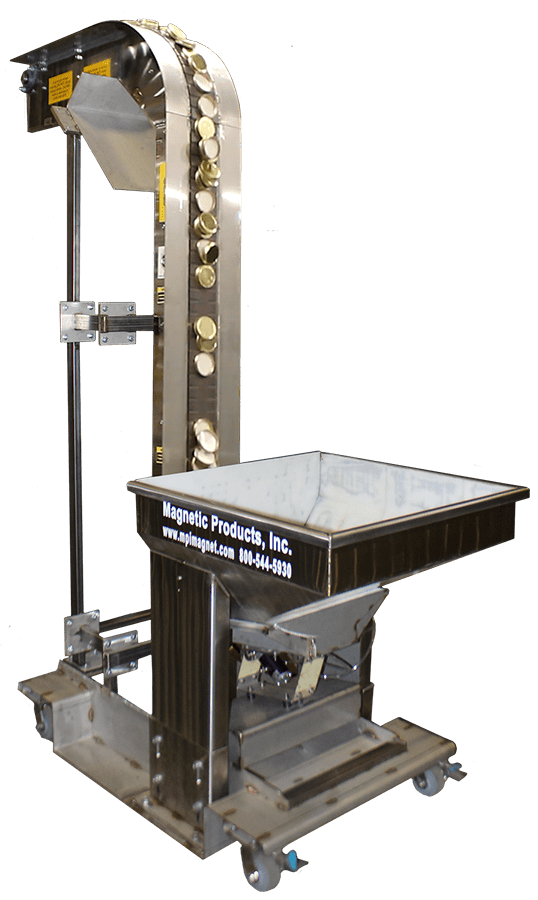

MPI’s Magnetic Rails and Pulleys are designed for easy installation into new or existing belted conveyors or other material handling equipment. Magnetic Box Rails are used to hold and position ferrous or partly ferrous parts. They are ideal for use in “can handling” conveyor systems. The rail’s strong magnetic field is completely contained within the working surface and is extremely effective in applications which require a high “reach out” magnetic field. Magnetic Box Rails are used to save floor space by elevating parts up steep inclines; vertically change the direction of moving parts quickly; control the speed of moving parts to accelerate or decelerate; stabilize and hold parts in position, or magnetically separate ferrous parts from non-ferrous materials in conveying and processing lines.

Benefits of Magnetic Rails and Pulleys From Magnetic Products, Inc

Magnetic Rails

- 100% stainless steel cover

- Powerful ceramic 8 magnet material

- Mild steel backing plate

- Heavy-duty welded construction

Pulleys

- Powerful Ceramic 8 permanent magnet material

- Stainless steel face

- Rugged, all-welded construction

- 3 different magnetic circuits available

- Face widths from 8” – 62”

- Roll diameters from 4” – 36”

Magnetic Rails and Pulleys Product Details

How It Works

Magnetic Box Rails and T Type Box Rails are usually mounted in tandem with magnetic pulleys and other rails beneath a conveyor’s belt. The standard design provides quick installation to a conveyor’s framework or table and can be custom designed and manufactured to fit your specifications.

Pulleys are typically used as transfer devices in belt conveyors. As metal nears the pulley’s magnetic field, it is attracted and held to the conveyor’s belt until it reaches the transfer point.

Product Options

- Rails

- Rigidized face-plate

- Angled infeed and discharge ends, to match pulley

- Tapering magnetic fields

- Curved rails for 30°, 45°, 60°, or 90° turns and inside or outside radii from 4” to 72”

- Custom face-plate flanges

- Custom mounting holes

- Non-standard magnetic polarities

- Multiple lane magnetic fields

- Pulleys

- Magnet Faces

- Flat Stainless Steel (FS): This is the most economical option offered and provides a durable non-magnetic stainless steel belt running surface.

- Flat Stainless Steel with Centering Track Bar (FSTB): This is an economical way to provide a degree of center belt tracking, without the expensive costs of crowning.

- Crowned Stainless Steel (CS): This is the most expensive option and offers a durable non-magnetic stainless steel-belt running surface with a belt centering crown.

- Crowned Vulcanized Rubber (CVR): This option offers both an economical way to provide a belt-centering crown design and improved belt traction.

- Crowned Vulcanized and Lagged Rubber (CVRL): This option can be added to any vulcanized rubber roll where belt traction is critical. It is available in a variety of standard patterns, such as herringbone, diamond, etc.

- Magnet Faces

Specifications

US Customary Units

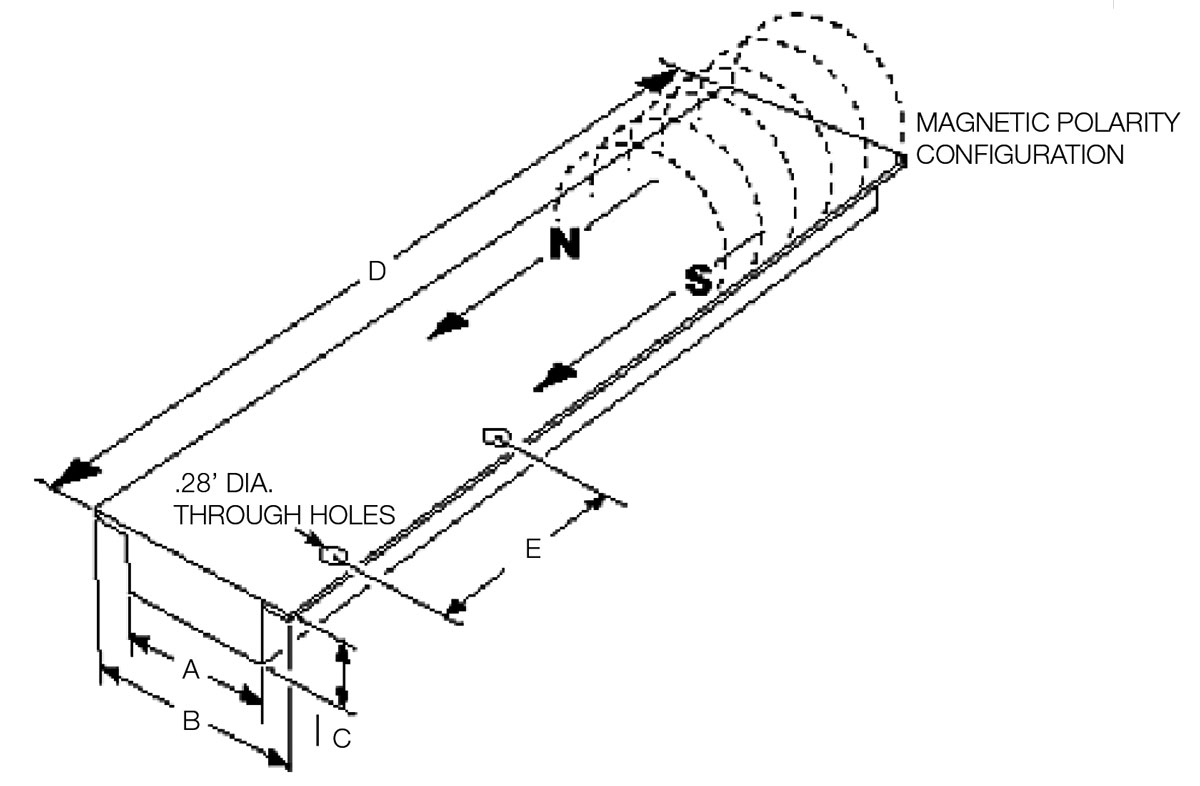

| Model # | Width (A) | Width (B) | Thickness (C) | Length (D) | Tap Distance (E) |

||

| Box Rail Series | |||||||

| BR-2 | 2.63″ | Built to customer’s specifications (1″ flange, standard) | 0.56″ | Built to customer specifications (up to 8″) | Built to customer specifications (12″ on-center in backplate standard) | ||

| BR-4 | 4.19″ | 0.81″ | |||||

| BR-6 | 4.19″ | 1.06″ | |||||

| BR-8 | 4.19″ | 1.31″ | |||||

| BR-12 | 4.19″ | 1.94″ | |||||

| BR-16 | 5.19″ | 2.56″ | |||||

| BR-24 | 8.19″ | 4.06″ | |||||

| T Type Box Rail Series | |||||||

| BRT-2 | 2.63″ | Built to customer’s specifications (1″ flange, standard) | 0.56″ | Built to customer specifications (up to 8″) | Built to customer specifications (12″ on-center in backplate standard) | ||

| BRT-4 | 4.19″ | 0.81″ | |||||

| BRT-6 | 4.19″ | 1.06″ | |||||

| BRT-8 | 4.19″ | 1.31″ | |||||

| BRT-12 | 4.19″ | 1.94″ | |||||

| BRT-16 | 5.19″ | 2.56″ | |||||

| BRT-24 | 8.19″ | 4.06″ | |||||

Metric Units

| Model # | Width (A) | Width (B) | Thickness (C) | Length (D) | Tap Distance (E) |

|

| Box Rail Series | ||||||

| BR-2 | 66mm | Built to customer’s specifications (25mm flange, standard) | 14mm | Built to customer specifications (up to 203mm) | Built to customer specifications (305mm on-center in backplate standard) | |

| BR-4 | 106mm | 21mm | ||||

| BR-6 | 106mm | 27mm | ||||

| BR-8 | 106mm | 33mm | ||||

| BR-12 | 106mm | 49mm | ||||

| BR-16 | 132mm | 65mm | ||||

| BR-24 | 208mm | 103mm | ||||

| T Type Box Rail Series | ||||||

| BRT-2 | 67mm | Built to customer’s specifications (25mm flange, standard) | 14mm | Built to customer specifications (up to 203mm) | Built to customer specifications (305mm on-center in backplate standard) | |

| BRT-4 | 106mm | 21mm | ||||

| BRT-6 | 106mm | 27mm | ||||

| BRT-8 | 106mm | 33mm | ||||

| BRT-12 | 106mm | 49mm | ||||

| BRT-16 | 132mm | 65mm | ||||

| BRT-24 | 208mm | 103mm | ||||