M-200 Electric Scrap Shaker

Simple Scrap Management

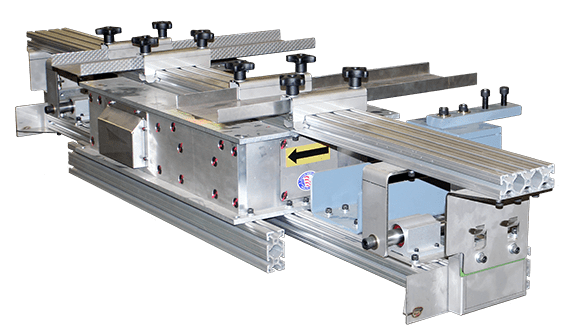

The patented M-200 Electric Shaker Conveyor is designed to remove scrap metal from medium to large stamping presses that require up to a 180” (15’) crossbar or larger using dual systems. This scrap removal conveyor makes scrap management simple. The turnkey scrap handling system is designed to start handling scrap right out of the crate. Simply mount it to the presses T-slots, connect it to 110v power and attach your pans (supplied by MPI or end user), then power on the unit. The system is designed to run without the need for maintenance, air, or lubrication. The scrap conveyor runs at a fixed speed (factory preset at the optimal setting). Items that can be tampered with and may slow production, such as buttons, controls or dials, have been eliminated.

Patent: #US-008,752,695-B2

Benefits of the M-200 Electric Scrap Shaker From Magnetic Products, Inc

The Most Reliable Solution to Stay Up and Running

- MPI patented electric shakers are the most reliable scrap removal conveyor available. They deliver years of dependable service and have a modular design, so if something does go wrong, you can get back up and running quickly.

Exclusive Rack & Pinion Design

- Most large electric scrap shakers fail because they cannot handle the uneven pan loads, which are required for stamping applications. MPI’s exclusive rack and pinion design delivers an even load to the drive no matter how lopsided your pan setup needs to be for your die. This results in years of reliable service without downtime, even on the largest press applications. (Note: for any press applications over 180” wide, MPI will supply two evenly sized systems that cover the width required.)

Easy Installation

- Plug and play design slides into 2 or 4 t-slots on the press, locks down by tightening a bolt and plug into a standard 110V plug.

Optional Cart for Quick Changeover

- An optional cart with casters and adjustable height enable to system to be easily moved around the pressroom and adapt to different die heights.

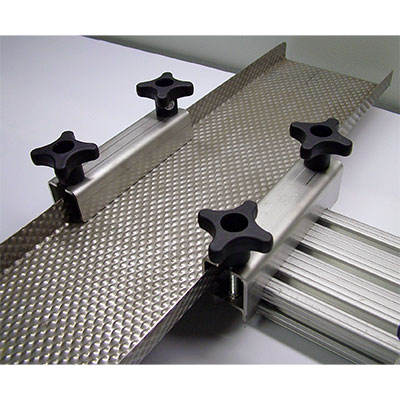

Quick-Release Pan Mount Brackets

- Optional Quick-Release Pan Mount Bracket Accessory make it easy to add, remove and slide pans on the extrusion when setting up for a new die.

Extremely Efficient

- A compact electric motor drives the scrap conveyor. Compared to previously used pneumatic designs, the electric design can reduce operating costs by 71%.

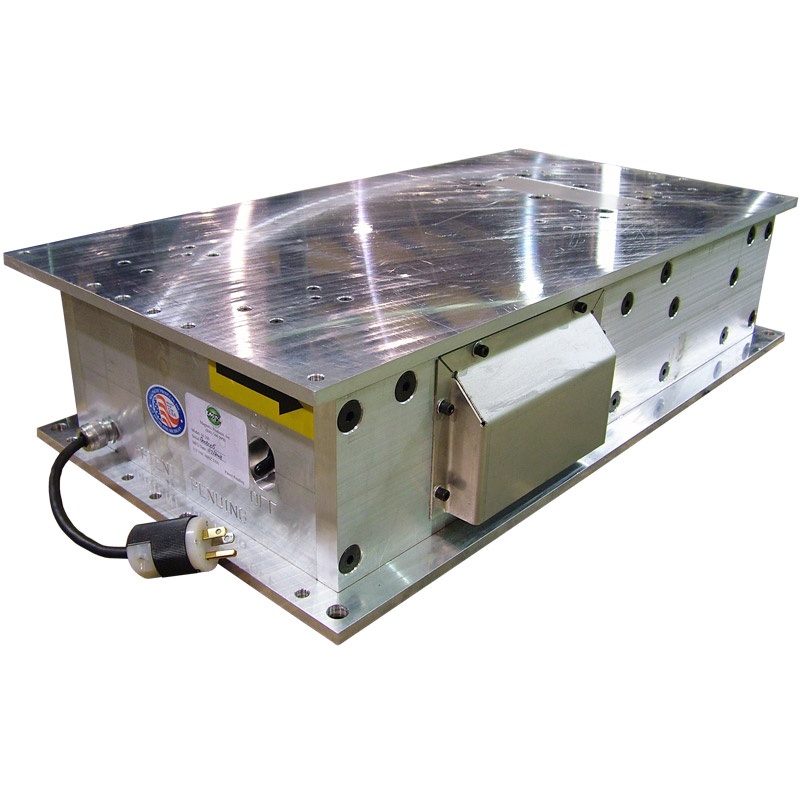

Heavy-Duty Billet Aluminum Construction

- The press room can be an abusive environment for equipment. Our electric scrap shakers are built with heavy duty 1” thick aluminum billet construction that is lightweight for the drive, but strong enough to stand up to anything in the press room, except a die being dropped on it.

Easy to Reverse Direction of Travel

- The scrap shaker can easily reverse direction of travel for the scrap by unmounting, turning 180 degrees and remounting.

Quiet Operation

- Noise compounds in the press room, and you do not need your scrap system adding to the overall noise. The electric shaker runs almost silently, allowing operators to focus on their work.

No Air or Lubrication Required

- The electric drive saves on maintenance and compressor operating costs when compared to pneumatic design.

Simple On/Off Switch to Operate

- The scrap shaker features a simple on/off switch located on the side of the unit to turn it on and off.

Excellent Service and Support

- MPI understands that if these systems are not running, you cannot run your press. Should the unexpected occur, MPI has spare units on the shelf, a repair program and a 24/7 number so you can know you can reach us even if it is 2am on a Sunday.

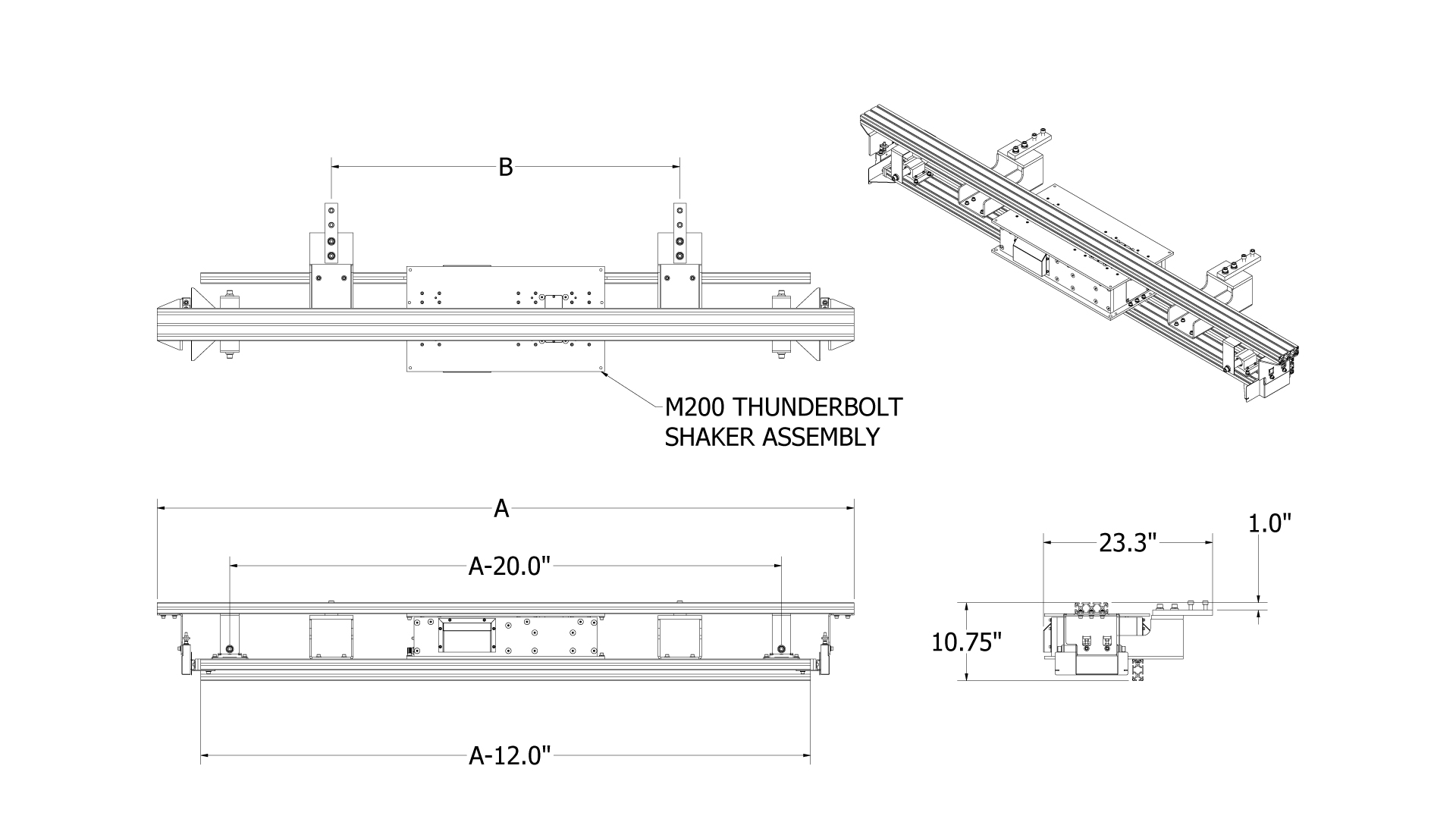

M-200 Electric Scrap Shaker Product Details

How It Works

The M Series press mounted scrap conveyor moves scrap metal by driving metal pans using our patented electric shaker motor. This motor creates a slow, low frequency movement with a quick return that drives stamping scrap forward. The motor is attached to the bolster through one or more T-slot mounts. The tongue of the mounts will fit into any standard T-slot. Once in place, the tongue can be tightened down and then the scrap systems motor is securely attached to the bolster.

A crossbar made from extruded aluminum is attached to the top plate of the electric shaker conveyor, perpendicular to the part movement. The crossbar allows the operator to attach a metal pan to convey the scrap with the use of a set of Quick Release Pan Mount Bracket Accessory. One set is required for each pan that is attached to the electric shaker. Once attached, the pan can be slid forward and backward in the brackets, left and right on the crossbar, to properly position the pan between the uprights on the die where the scrap will fall. Once the metal pans are properly positioned, they can be hand tightened to lock them into place while the press is in operation.

Multiple pans of varying sizes can be attached to a single crossbar as needed for the setup of the die that is being run. MPI suggests running a balanced load across the width of the crossbar for models M-10 and M-50 scrap removal systems. The M-200 Rack and Pinion System does not require an even pan load.

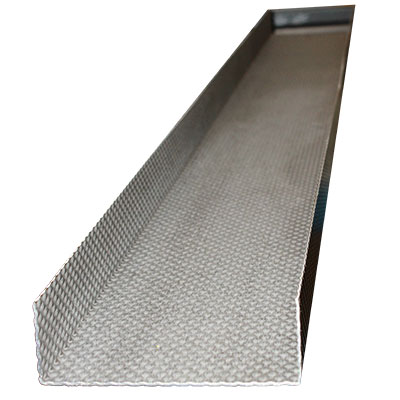

Shaker pans can be manufactured by MPI or by the customer and of from any type of steel construction. Rigidized pans are recommended for applications that are heavy in oil to help break surface tension for part movement. They can be manufactured in any shape or size that is required by the application to capture all the scrap from coming from the die. Generally, the pan width matches the width between the uprights leaving a small amount of room for clearance and has a side height of 1-2” tall. When the shaker conveyor is installed, it should be installed so that the top of the crossbar is level with the height of the bolster. Then when the pan is attached, it can be supported by the bolster.

With the scrap removal conveyors setup, it is ready to be powered on. There is a manual switch on the electric shaker used to power on the unit. If operators prefer to operate the unit remotely, this can be done this by leaving the shaker motor in the powered-on position and adding a switch closer to the press controls or integrating it with the press controls.

The scrap handling equipment operates almost silently and uses a high efficiency motor to reduce operating costs. Compared to pneumatic scrap shaker designs, the MPI electric scrap shakers can operating costs by up to 71% and requires no maintenance. It is designed to reliably convey scrap metal at a rate of 20 FPM.

The MPI M-200 Rack and Pinion Electric Scrap Shaker Conveyor is often integrated with a Steel Belt Conveyor, Beltless Magnetic Conveyor or underground scrap shaker for a complete scrap handling system.

Product Options

Scrap Shaker Trays or Scrap Shaker Pans

- MPI can provide new or replacement shaker pans for your electric shaker for scrap conveying. These can be manufactured from carbon steel, stainless steel, or rigidized carbon steel. Each pan is made to the size required for the specified application or die that is being run.

|

|

| Rigidized Pan | Smooth Pan |

Quick Release Pan Mount Bracket Accessory (QRPMB)

- Shaker pan should always be securely mounted to the crossbar to ensure proper scrap transfer and protect the pans and motor from damage. MPI Quick Release Pan Mount Bracket Accessory are designed to make adding, removing or moving shaker pan quick and easy for operators in between die changes. Once tightened by hand, the mounting system securely attaches the pan to the crossbar. This metal mounting system does not use any plastic that wears out over time and is lightweight so it does not impact the long term performance of the shaker system. One set is required for each pan. A set includes a left and right hand pan attachment.

- The bracket sizing is based on your mounting cross bar, width of the crossbar correlates to size.

- The M-200 Rack and Pinion Electric Scrap Shaker Conveyor uses the Model Number QRPMB-1.5X3.0 for the 3″ extrusion size.

|

| Quick Release Pan Mount Brackets |

Wear Pad Kits

- When pans are installed, they can be supported by the bolster. If there are any concerns for wear, uneven surfaces, or insufficient pan support. MPI offers wear pad kits that can be attached to the bottom of the pans. These raise the pan off the bolster and make the wear pad the wear item that can be replaced as needed.

Carts

- Depending on the setup of the press, the shaker system may need to be moved during die changes or to the opposite side for a different setup. Carts make it easy to roll the press mounted shaker system without the use of a forklift. This also protects the system from any damage that could be caused from the forklift or impacts that may occur during transfer. Carts are designed for each application to match the bolster height required. The shaker system carts can be adjustable in height to adapt as needed for different dies. Typically, these cart systems use the standard T-slot mounts on the rack and pinion system to attach it to the bolster, but quick connect and release systems can be used for quicker changeover when needed.

|

| Example M-200 Electric Scrap Shaker Conveyor with Cart |

Specifications

| M-200 Scrap Conveyor Specifications |

||||||||

| Model Number | Crossbar Width | Power Input | Design Capacity (Pans and Scrap) |

System Weight | T-Slot Sizes | Rack and Pinion System Included | Number of Bolster Mounts | Quick Release Pan Mount Brackets |

| M-200 Motor Only | Not Included | 110 VAC, single phase | 200 lbs | 165 | Not Included | No | Not Included | Not Included |

| M-200-MP4 | 48″ | 110 VAC, single phase | 200 lbs | 175 | 3/4″ Thick x 1.75″ wide | No | 2 | Not Included |

| M-200-MP5 | 60″ | 110 VAC, single phase | 200 lbs | 188 | 3/4″ Thick x 1.75″ wide | No | 2 | Not Included |

| M-200-MP6-RP | 72″ | 110 VAC, single phase | 200 lbs | 236 | 3/4″ Thick x 1.75″ wide | Yes | 2 | Not Included |

| M-200-MP7-RP | 84″ | 110 VAC, single phase | 200 lbs | 245 | 3/4″ Thick x 1.75″ wide | Yes | 2 | Not Included |

| M-200-MP8-RP | 96″ | 110 VAC, single phase | 200 lbs | 254 | 3/4″ Thick x 1.75″ wide | Yes | 2 | Not Included |

| M-200-MP9-RP | 108″ | 110 VAC, single phase | 200 lbs | 264 | 3/4″ Thick x 1.75″ wide | Yes | 2 | Not Included |

| M-200-MP10-RP | 120″ | 110 VAC, single phase | 200 lbs | 313 | 3/4″ Thick x 1.75″ wide | Yes | 2 | Not Included |

| M-200-MP11-RP | 132″ | 110 VAC, single phase | 200 lbs | 322 | 3/4″ Thick x 1.75″ wide | Yes | 2 | Not Included |

| M-200-MP12-RP | 144″ | 110 VAC, single phase | 200 lbs | 331 | 3/4″ Thick x 1.75″ wide | Yes | 4 | Not Included |

| M-200-MP13-RP | 156″ | 110 VAC, single phase | 200 lbs | 340 | 3/4″ Thick x 1.75″ wide | Yes | 4 | Not Included |

| M-200-MP14-RP | 168″ | 110 VAC, single phase | 200 lbs | 350 | 3/4″ Thick x 1.75″ wide | Yes | 4 | Not Included |

| M-200-MP15-RP | 180″ | 110 VAC, single phase | 200 lbs | 360 | 3/4″ Thick x 1.75″ wide | Yes | 4 | Not Included |