ElectroPermanent Chuck Control Unit

Reliable Magnetization and Demagnetization

The ElectroPermanent power supply and control units are designed to magnetize and demagnetize all types of ElectroPermanent magnetic devices, depending on factory settings. MPI offers several control units, depending upon size and the number of chucks. In case of other magnetic device brands and models, consult MPI. EPCU control units are named by the number of output channels (i.e., number of electrical circuits to be energized in the magnetic clamping system): EPCU10: 1 channel, EPCU20: 2 channels, and EPCU40: 4 channels.

Benefits of the ElectroPermanent Chuck Control Unit From Magnetic Products, Inc

- EPCU control units come in two different versions:

- SW for single wave rectified output voltage

- DW for double-wave (full wave) rectified output voltage

- Operational safety – the machine cannot be started up at a low holding force

- Safe magnetization level setting

- Effective demagnetization of the chuck and the workpiece for easy removal

- Control of the chuck via remote controller available

- Control one or more magnets at the same time (depending on selected unit type)

- One (1) year warranty

- Models 10SW and 10DW use U19 Control style. All other models use RM control style.

- U19: No channel selection possible but it can be used with EP-CU20 and 40

- Mag and demag cycles will start for all channels

- RM : Channel selection possible

ElectroPermanent Chuck Control Unit Product Details

How It Works

The ElectroPermanent Chuck Control Units are designed to magnetize and demagnetize all types of ElectroPermanent magnetic devices depending on its factory settings. The magnetization cycles consist of one or several positive voltage pulses. The demagnetization cycles consist of a specific combination of alternating positive and negative voltage pulses. Note: The work piece material may retain some residual magnetism due to its chemical and magnetic properties.

Specifications

When to choose the ElectroPermanent Chuck Control Unit:

The ElectroPermanent power supply and control units are designed to magnetize and demagnetize all types of ElectroPermanent magnetic devices, depending on its factory settings. MPI offers several control units depending upon size and number of chucks. In case of other magnetic device brands and models, consult MPI.

EPCU control units are named by the number of output channels (i.e., number of electrical circuits to be energized in the magnetic clamping system):

- EPCU10: 1 channel

- EPCU20: 2 channels

- EPCU40: 4 channels

EPCU control units also come in two different versions:

- SW for single wave rectified output voltage.

- DW for double-wave (full wave) rectified output voltage.

| Model SW for Single-Wave Rectified Output Voltage | ||||||||||||

| Part Number | Description | Number of Chuck & Size | Main Operating Voltage (Vac) | Main Operating Frequency (Hz) | Operating Temperature (ºF) | Maximum Relative Humidity | Maximum Working Altitude (ft) | Cabinet Protection Class | Required Circuit Breaker | Required Power Cable (*) | Number of Output Channels | |

| EPCU-10SW | ElectroPermanent Chuck Control Remote Control (RC-EPC) included | 1 chuck sizes to 16” x 32” | 200-460 | 50/60 | 32-122 | 90% | 3,280 | IP66 | 32A-D | 3 G 4 | 1 | |

| EPCU-20SW | ElectroPermanent Chuck Control for 2 chuck sizes to 16” x 32” Remote Control (RC-EPC) included | 2 chuck sizes to 16” x 32” | 200-460 | 50/60 | 32-122 | 90% | 3,280 | IP66 | 40A-D | 3 G 6 | 4 | |

| EPCU-40SW | ElectroPermanent Chuck Control Remote Control (RC-EPC) included | 4 chuck sizes to 16” x 32” | 200-460 | 50/60 | 32-122 | 90% | 3,280 | IP66 | 40A-D | 3 G 6 | 2 | |

| *Cable between electrical grid and control unit is not supplied. Make sure to follow required cable specifications. |

||||||||||||

| Model SW for Double-Wave (Full Wave) Rectified Output Voltage | ||||||||||||

| Part Number | Description | Number of Chuck & Size | Main Operating Voltage (Vac) | Main Operating Frequency (Hz) | Operating Temperature (ºF) | Maximum Relative Humidity | Maximum Working Altitude (ft) | Cabinet Protection Class | Required Circuit Breaker | Required Power Cable (*) | Number of Output Channels | |

| EPCU-10DW | ElectroPermanent Chuck Control Remote Control (RC-EPC) included | 1 chuck sizes to 16” x 32” | 200-460 | 50/60 | 32-122 | 90% | 3,280 | IP66 | 40A-D | 3 G 6 | 2 | |

| EPCU-20DW | ElectroPermanent Chuck Control Remote Control (RC-EPC) included | 2 chuck sizes to 16” x 32” | 200-460 | 50/60 | 32-122 | 90% | 3,280 | IP66 | 40A-D | 3 G 6 | 1 | |

| EPCU-40DW | ElectroPermanent Chuck Control Remote Control (RC-EPC) included | 4 chuck sizes to 16” x 32” | 200-460 | 50/60 | 32-122 | 90% | 3,280 | IP66 | 50A-D | 3 G 10 | 4 | |

| *Cable between electrical grid and control unit is not supplied. Make sure to follow required cable specifications. |

||||||||||||

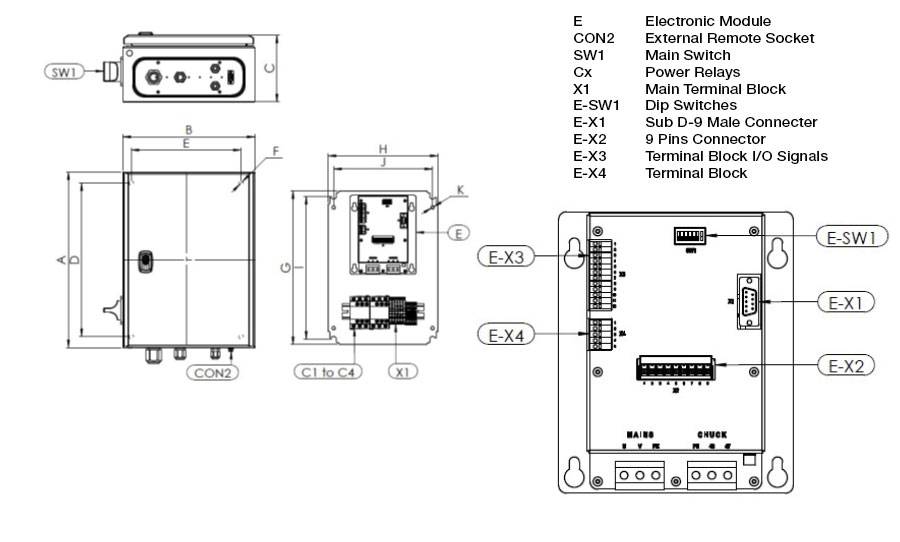

US Customary Units

| Part Number | Dimensions (Inches) |

||||||||||

| A | B | C | D | E | F | G | H | I | J | K | |

| EPCU-10SW | 12 | 10 | 6 | 9.8 | 7.9 | 0.4 | 9.8 | 7.9 | 8.9 | 6.9 | 0.4 |

| EPCU-10DW | 16 | 12 | 6 | 13.8 | 9.8 | 0.4 | 13.8 | 9.8 | 12.8 | 8.9 | 0.4 |

| EPCU-20SW | 16 | 16 | 8 | 13.8 | 13.8 | 0.4 | 13.8 | 13.8 | 12.8 | 12.8 | 0.4 |

| EPCU-20DW | 16 | 12 | 6 | 13.8 | 13.8 | 0.4 | 13.8 | 9.8 | 12.8 | 8.9 | 0.4 |

| EPCU-40SW | 16 | 16 | 8 | 13.8 | 13.8 | 0.4 | 13.8 | 13.8 | 12.8 | 12.8 | 0.4 |

| EPCU-40DW | 19.7 | 16 | 8 | 17.7 | 17.7 | 0.4 | 17.7 | 13.8 | 12.8 | 16.7 | 0.4 |

Metric Units

| Part Number | Dimensions (Millimeters) |

||||||||||

| A | B | C | D | E | F | G | H | I | J | K | |

| EPCU-10SW | 305 | 254 | 152 | 249 | 201 | 254 | 249 | 201 | 226 | 175 | 325 |

| EPCU-10DW | 406 | 305 | 152 | 351 | 249 | 325 | 351 | 249 | 325 | 226 | 325 |

| EPCU-20SW | 406 | 406 | 203 | 351 | 351 | 325 | 351 | 351 | 325 | 325 | 325 |

| EPCU-20DW | 406 | 305 | 152 | 351 | 351 | 325 | 351 | 249 | 325 | 226 | 325 |

| EPCU-40SW | 406 | 406 | 203 | 351 | 351 | 325 | 351 | 351 | 325 | 325 | 325 |

| EPCU-40DW | 500 | 406 | 203 | 450 | 450 | 325 | 450 | 351 | 325 | 242 | 325 |

Related Resources

Locate a Distributor

| Distributor Name | Distributor | Product Part Number | Product URL |

| EPCU-10SW |  |

EPCU-10SW | https://www.penntoolco.com/mpi-electropermanent-chuck-control-unit-single-wave-rectified-output-voltage-1-channel-epcu-10sw/ |

| EPCU-10DW |  |

EPCU-10DW | https://www.penntoolco.com/mpi-electropermanent-chuck-control-unit-double-wave-full-wave-rectified-output-voltage-1-channel-epcu-10dw/ |