Metal Detector R (Ring Sensor)

Applications in the Medical-Pharmaceutical Sector

The R types provide the highest performance in detecting magnetic and non-magnetic metals. Typically, applications are in the medical-pharmaceutical sector as well as sanitary items, foods, and chemical powders. The product falls through the R sensor head. An optional reject unit will promptly separate the smallest metal objects out of the goods stream. Reject Device for R Sensor Head: Metal particles are rejected automatically. Reject timing through the metal detector control box. Pneumatic drive system. The METAL SHARK® R is generally used for: Sanitary items Pharmaceuticals Chemical powders High-end plastic resins

Benefits of the Metal Detector R (Ring Sensor) From Magnetic Products, Inc

- Full 2 year warranty on complete system–giving you peace of mind

- Hygienic food industry design-ensures compliance with good manufacturing principles

- Semi-flexible aperture lining–resists thermal shock due to temperature change and protects the sensor for maximum operating life and minimum down time

- All solid state electronics housed on one main board–ensures years of reliable performance offering the lowest cost of ownership on the market

- Intuitive menu structure–simple operation for reliable performance, no expensive service calls to adjust settings

- Full HACCP compliance–demonstrates your due diligence, ensures you and your customers are protected

- Full pre-sale applications and custom design service–making sure we provide the right solution first time

- Satisfaction guarantee–put simply, the unit will perform as specified or we will take it back for a full refund

Metal Detector R (Ring Sensor) Product Details

Product Options

- SHARKNET® software

- Monitor real-time inspection results and actively manage product inspection equipment from a central computer

- Enables automatic downloading of data documentation to a Windows-based PC

- Support required compliance with: HACCP-SQF 2000-BRC-GMP-IFS5-FSSC 22000/PAS 220

- Remote maintenance capability by operators and Cassel technicians

- All data is stored in an SQL database for easy export or integration if needed

Specifications

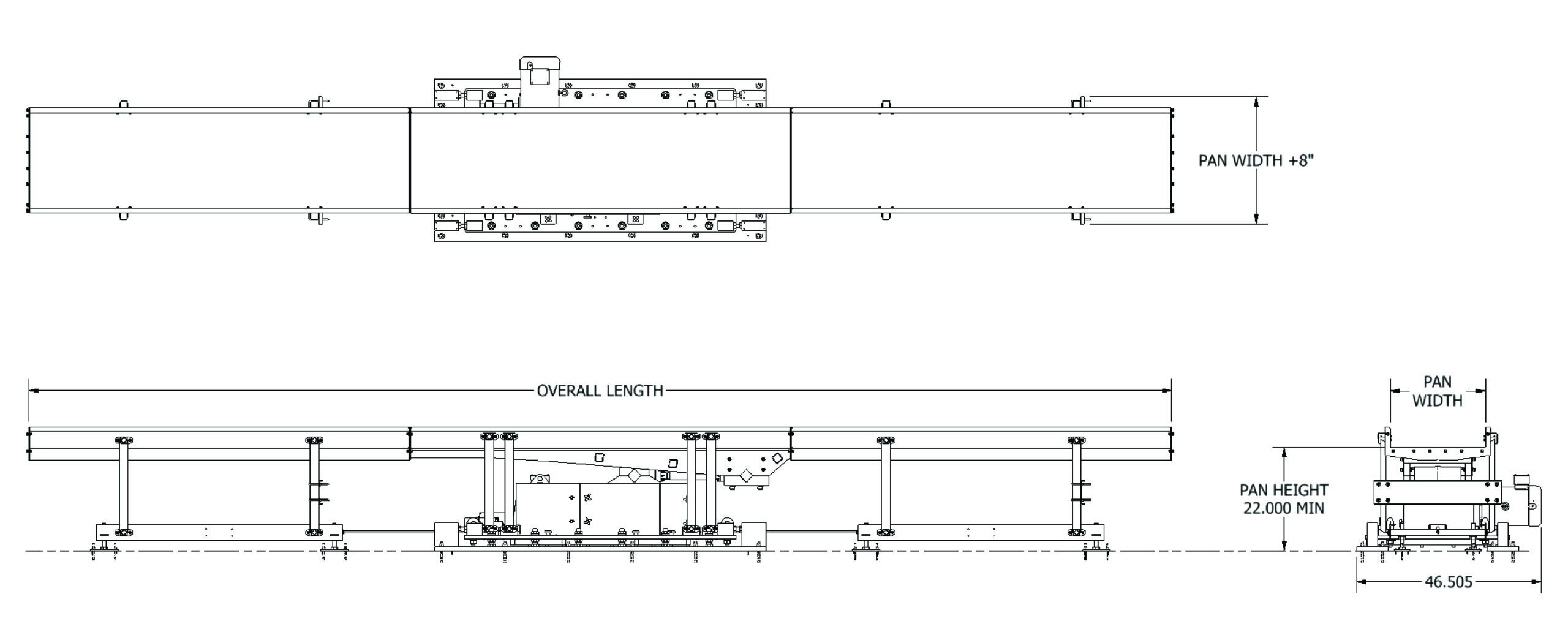

Most key dimensions called out in the above drawing are based on system configurations from the Options tab. During the assessment process, MPI will evaluate your plant system layout and help configure the system to fit into your installation location.

Most key dimensions called out in the above drawing are based on system configurations from the Options tab. During the assessment process, MPI will evaluate your plant system layout and help configure the system to fit into your installation location.