Sharknet Software Controller

Simplified Reporting

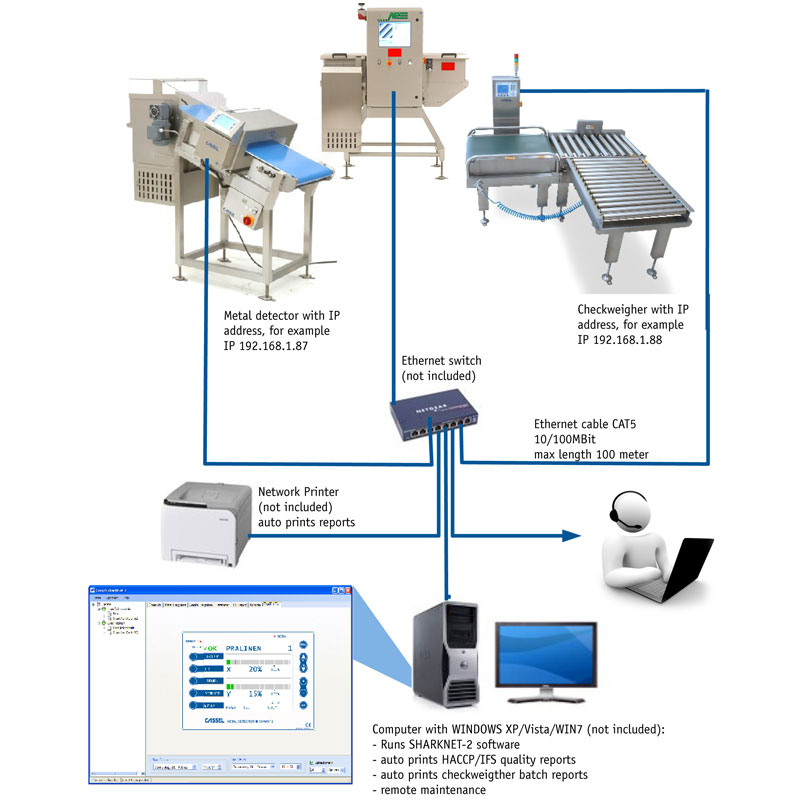

SHARKNET provides automatic documentation of operational data for metal detectors. The SHARKNET®-2 Software networks all METAL SHARK® metal detector machines with one Windows computer. SHARKNET®-2 simplifies reporting for HACCP, GMP, BRC and IFS compliance. The software collects all the required data and prints out any user-defined report requests.

Benefits of the Sharknet Software Controller From Magnetic Products, Inc

- Sharknet Sofware

- Managers can monitor real-time inspection results and actively manage multiple product inspection equipment from a central computer

- Remote maintenance capability by operators and Cassel technicians

- Traceability of all operational data including metal alerts, batch and average weight reports, parameter changes, PVS results, errors, and product passes

- All data is stored in an SQL database for easy export

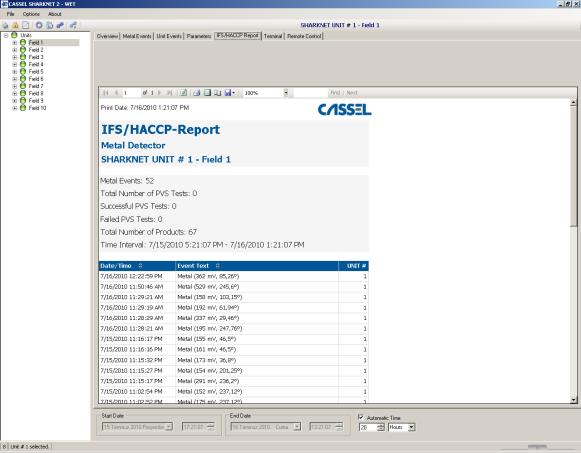

- Auto report printing for simple HACCP-SQF 2000-BRC-GMP-IFS5-FSSC 22000/PAS 220 compliance

- Backup of all stored parameters

- Enhanced features include:

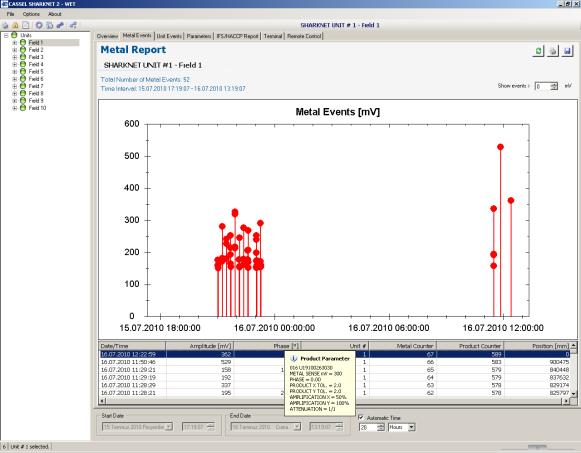

- Quick, easy viewing and printing of HACCP reports

- Backup and restoring of metal detector parameters

- Software password protection

Sharknet Software Controller Product Details

How It Works

SHARKNET® 2 is easy to use and intuitive. The operation is simple with installation into the familiar Windows environment. All functions are called up by a mouse click. All metal detector data will be displayed by point-and-click on the particular icons.

The database and the archive function enable the recall of any previous time span. For instance, it is possible to prove that metal detection was active during any historical production batch.

Report functions in Windows and Printing: IFS/HACCP/GMP/BRC Report, parameter sheet, graphic and text report of metal findings with metal detectors.

Specifications

| Shark-1 | Shark-2 | SharkNET | |

| Technology | 2-Channel analysis | 4-Quadrant Technology | Same as controller |

| Display | Alphanumeric LCD | 5.4″ color screen | Computer LCD |

| Frequencies | 1, 2 or 4 | 1, 2 or 4 | Same as controller |

| Sensitivity | Normal user achieves 80% of metal detectors maximum performance without expert optimization | Normal user achieves 90% of metal detectors maximum performance without expert optimization | Same as controller |

| Teach | 8 to 14 samples | 3 to 7 samples | Same as controller |

| Interface | Strong digital filters | Excellent digital filters | Same as controller |

| Outputs | (2) Potential Free (4) Programmable |

(2) Potential Free (8) Programmable |

Same as controller |

| Inputs | (4) Programmable | (8) Programmable | Same as controller |

| Language | Latin characters only | Global languages available | Same as controller |

| Memory | Integrated flash for 50 events | Integrated flash for 1000 events | Unlimited data logging capabilities in SQL database |

| Parameter Backup | No | No | To computer hard drive |

| # of Custom Products | 120 | 120 | Same as controller |

| Temperature | Standard: temp. -10 to + 50 °C humidity 30 to 85% not condensing |

Standard: temp. -10°C to +40°C, rel. humidity 30 to 85% not condensing; Options: -40°C or +55°C |

Same as computer |

| Power Input | 85-264 V AC,,50/60 Hz, 1P, self selecting | 85-264 V AC,,50/60 Hz, 1P, self selecting | Same as computer |

| Communication Interface | RS232, RS485 | RS232, Ethernet and optional WLAN | Same as computer |

| Password Protection | 1 Level | 4 Levels | Software is password protected |

| Multiple System Control | No | No | Yes |

| Remote Maintenance | No | No | Yes |

| Auto Report Printing | Metal event only to industrial printer | Yes, any report to network printer | Any report to PDF or network printer |

| Validation Software | Yes | Yes | Yes |