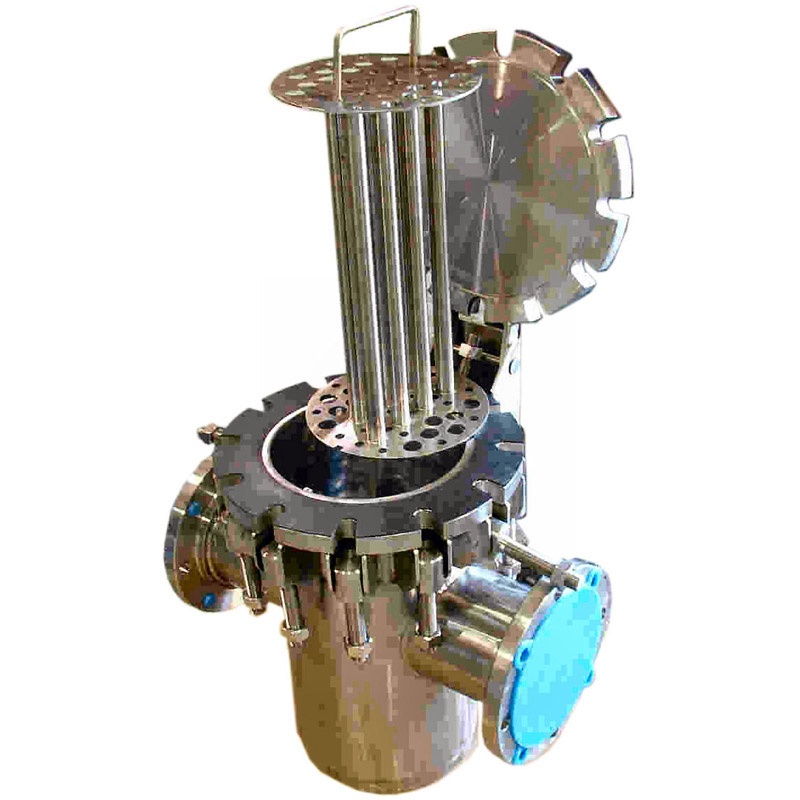

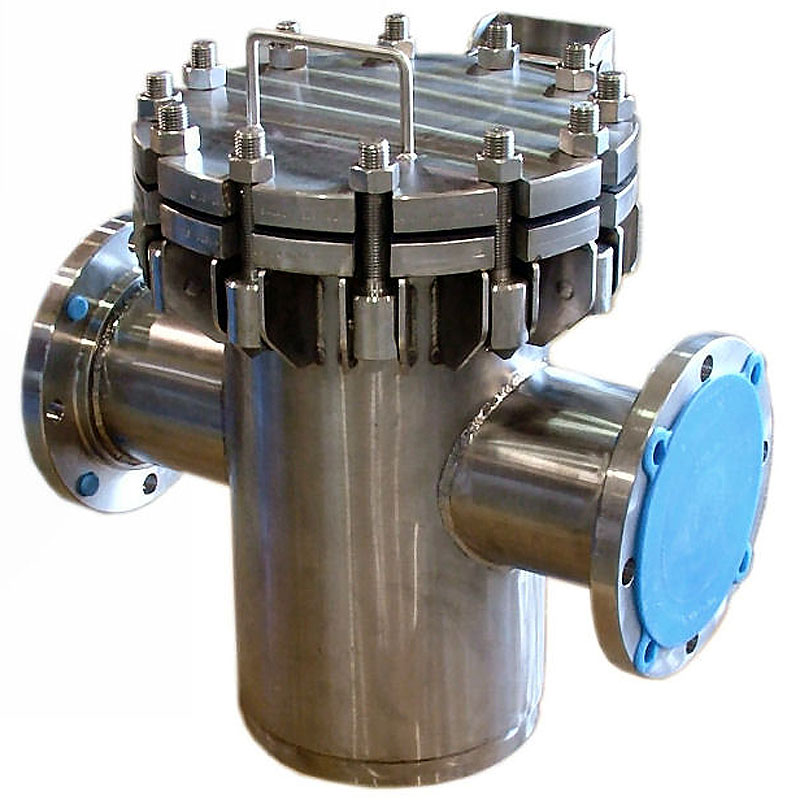

High Pressure Tube Liquid Trap Magnet

Protect Product Lines and Pumps

MPI’s High-Pressure Liquid Trap Magnet (Tube Design, High-Pressure) is designed to protect product lines and pumps by magnetically removing ferrous contaminants from the product stream. LFT-HP Series trap magnets provide purification of liquids and wet separation for a variety of industries; including but not limited to the chemical, food processing and paper milling.

At MPI, we help manufacturers control their metal. We provide peace of mind by manufacturing reliable industrial magnetitc and metal control equipment that removes contaminants, separates, or conveys metal in production processes.

Benefits of the High Pressure Tube Liquid Trap Magnet From Magnetic Products, Inc

- Powerful Ceramic magnet material

- 100% Stainless Steel construction

- 150 PSI max pressure, at 120°F

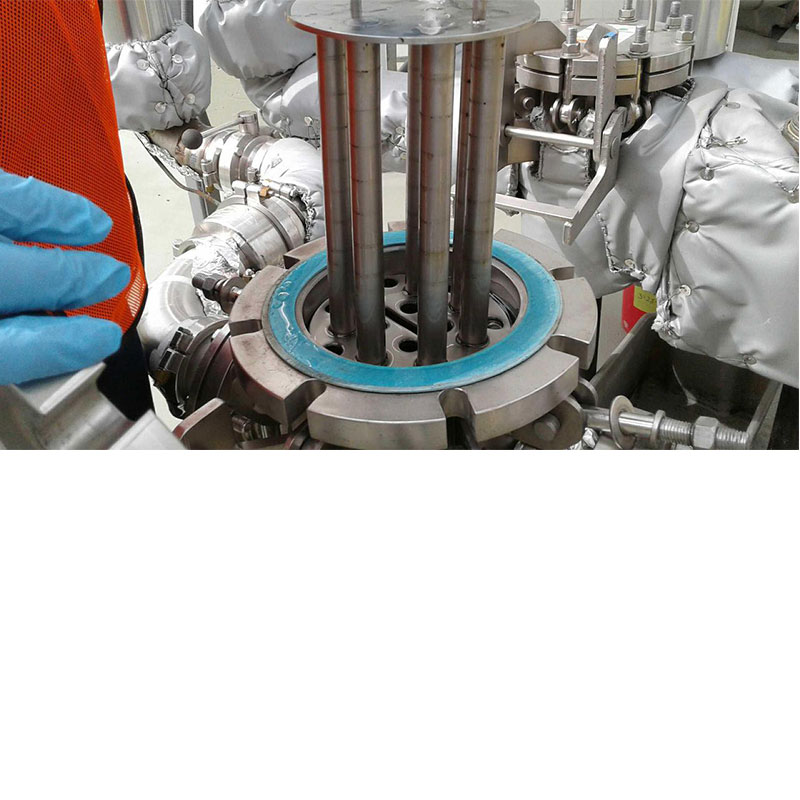

- Quick-release clamps provide easy removal for inspection and cleaning of magnetic element

High Pressure Tube Liquid Trap Magnet Product Details

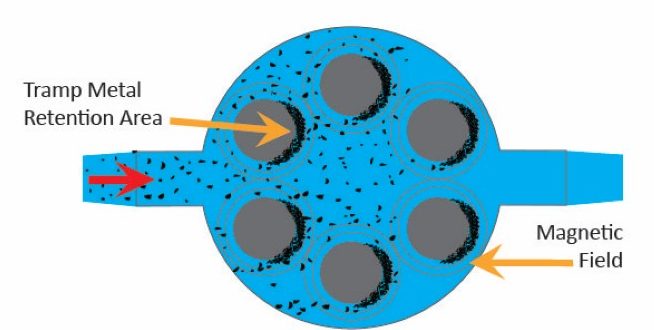

How It Works

The tramp metal collects at the downstream side of the magnetic tubes, preventing tramp metal “wash-off” during the continuous product flow around and through the magnetic field without restricting the product flow. Additionally, non-magnetic particles are trapped, by gravity, in a sump beneath the magnetic element.

Product Options

- Choice of magnet tube material:

- Ceramic 8 magnet material for less severe tramp metal applications

- Rare Earth magnet material for higher operating temperatures

- Hi-G material and Thin Wall designs for specialized applications

- Other line connection types available such as bevel seat, pipe thread, or weld ends

Specifications

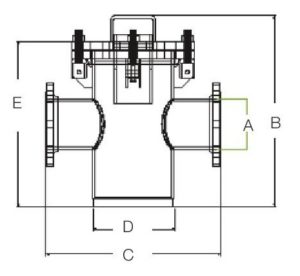

US Customary Units

| Model # | Inlet Pipe Diameter (A) |

Unit Height (B) |

Unit Diameter (D) |

Total Width (C) |

| IN | IN | IN | IN | |

| LFT-HP-3 | 3 | 24 | 10 | 23.188 |

| LFT-HP-4 | 4 | 24 | 10 | 23.188 |

| LFT-HP-5 | 5 | 26 | 10 | 23.188 |

| LFT-HP-6 | 6 | 26 | 10 | 23.188 |

| LFT-HP-8 | 8 | 32 | 16 | 26 |

| LFT-HP-10 | 10 | 32 | 18 | 29.812 |

Metric Units

| Model # | Inlet Pipe Diameter (A) |

Unit Height (B) |

Unit Diameter (D) |

Total Width (C) |

| MM | MM | MM | MM | |

| LFT-HP-3 | 76 | 610 | 254 | 589 |

| LFT-HP-4 | 102 | 610 | 254 | 589 |

| LFT-HP-5 | 127 | 610 | 254 | 589 |

| LFT-HP-6 | 152 | 610 | 254 | 589 |

| LFT-HP-8 | 203 | 813 | 406 | 660 |

| LFT-HP-10 | 254 | 813 | 457 | 757 |