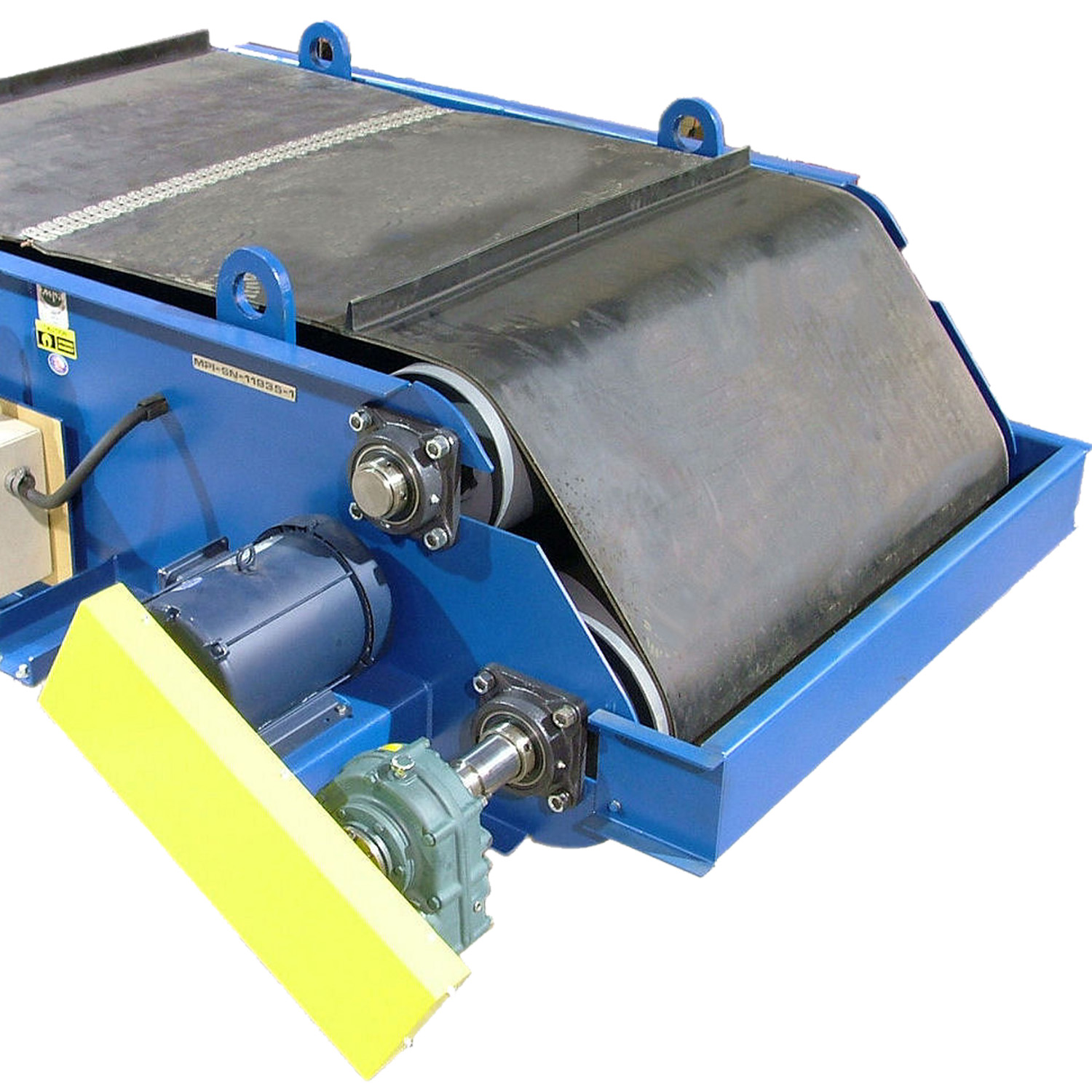

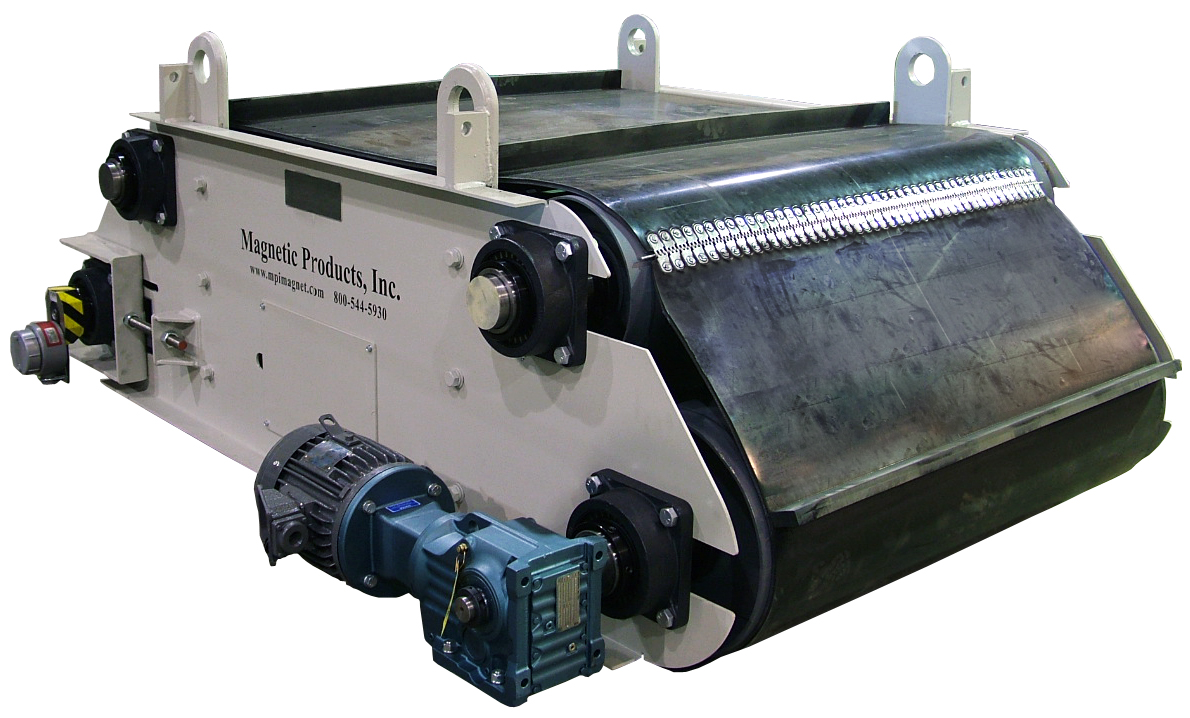

Self-Clean Suspended Electromagnet

Effective for Fast-Moving Conveyor Belts

MPI’s Self-Clean Suspended Electromagnets feature effective removal of unwanted tramp metal from heavy burden depths of material being conveyed by fast-moving conveyor belts. The Self-Clean Suspended Electromagnet has a conveyor belt moving across the magnet to automatically remove the collected tramp metal from the magnet face.

The powerful oil-cooled electromagnets are designed to remove large and medium tramp metal from conveyed product with large burden depths. Self-cleaning belt automatically removes captured tramp metal from magnets working surface.

Benefits of the Self-Clean Suspended Electromagnet From Magnetic Products, Inc

- 3-ply non-endless rubber belts with vulcanized rubber cleats

- 3 – 5 HP drive motors

- Shaft mounted speed reducer

- Self-aligning re-reaseable bearings

- Nonmagnetic belt fasteners

- Texaco (ASTM D3487) transformer cooling oil (specification sheet available upon request)

- Extremely powerful; manufactured with a high gradient balanced magnetic circuit

- Coils manufactured with Class “H” (or better) anodized aluminum strap for the “best in class” coil insulation performance

- Breather valve allows expansion and contraction without external expansion tank

- Durable Nomex and Glastic materials extend coil life

- Extra wide belt helps prevent tramp metal damage under the belt, extending belt and component life

- Crowned pulleys for accurate belt tracking

Self-Clean Suspended Electromagnet Product Details

How It Works

MPI’s Self-Clean Suspended Electromagnets feature effective removal of unwanted tramp metal from heavy burden depths of material being conveyed by fast-moving conveyor belts. The Self-Clean Suspended Electromagnet has a conveyor belt moving across the magnet to automatically remove the collected tramp metal from the magnet face.

Product Options

- Steel dust enclosures

- Zero-speed switches

- Special belts for abrasive, hot, or special applications

- Nonflammable coolant

- Static-conducting belts

- Belt sheave drive

- NEMA 4x enclosure

- Non-tandard motor voltage

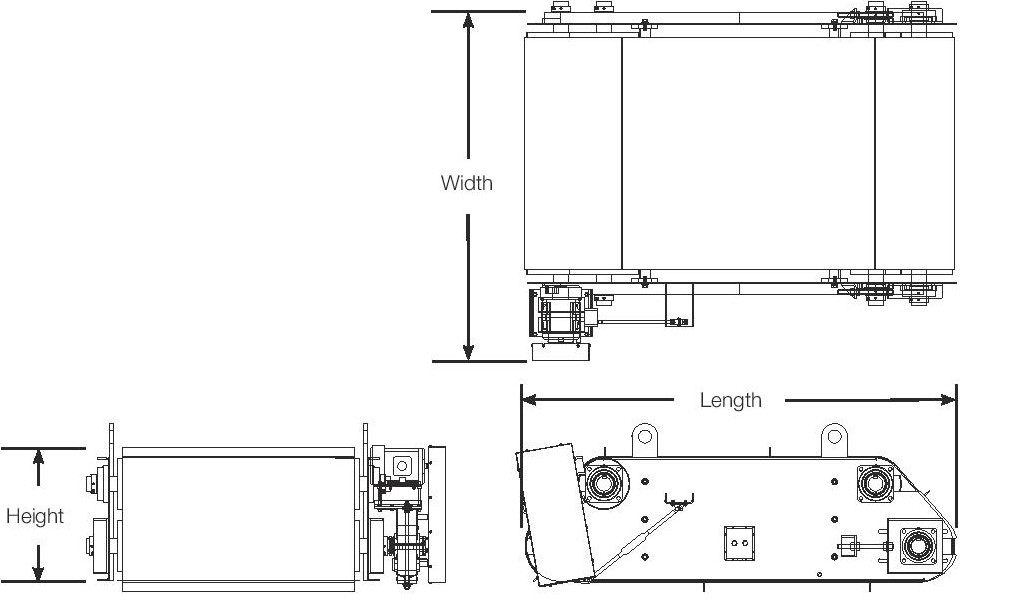

Specifications

US Customary Units

| ECBS Model # | Length | Width | Height | Belt Width | Weight | Voltage | Wattage | Motor |

| IN | IN | IN | IN | LBS | HP | |||

| ECBS-24 | 82 | 53 | 22 | 36 | 1,700 | 115 | 1300 | 3 |

| ECBS-30 | 88 | 59 | 29 | 42 | 2,800 | 115 | 4061 | 3 |

| ECBS-36 | 84 | 65 | 29 | 48 | 3,800 | 115 | 5150 | 3 |

| ECBS-42 | 100 | 71 | 33 | 54 | 5,100 | 115 | 6844 | 3 |

| ECBS-48 | 112 | 83 | 34 | 60 | 7,000 | 115 | 7885 | 3 |

| ECBS-54 | 112 | 83 | 34 | 66 | 9,300 | 115 | 9975 | 5 |

| ECBS-60 | 118 | 89 | 38 | 72 | 12,500 | 230 | 14436 | 5 |

Metric Units

| ECBS Model # | Length | Width | Height | Belt Width | Weight | Voltage | Wattage | Motor |

| CM | CM | CM | CM | KG | HP | |||

| ECBS-24 | 208.3 | 134.6 | 55.9 | 91.4 | 771.1 | 115 | 1300 | 3 |

| ECBS-30 | 223.5 | 149.9 | 73.7 | 106.7 | 1,270.1 | 115 | 4061 | 3 |

| ECBS-36 | 213.4 | 165.1 | 73.7 | 121.9 | 1,723.7 | 115 | 5150 | 3 |

| ECBS-42 | 254.0 | 180.3 | 83.8 | 137.1 | 2,313.3 | 115 | 6844 | 3 |

| ECBS-48 | 248.5 | 210.8 | 86.4 | 152.4 | 3,175.1 | 115 | 7885 | 3 |

| ECBS-54 | 248.5 | 210.8 | 86.4 | 167.6 | 4,218.4 | 115 | 9975 | 5 |

| ECBS-60 | 299.7 | 226.1 | 96.5 | 182.9 | 5,669.9 | 230 | 14436 | 5 |

Related Resources

- Video - Magnetic and Metal Detector Sorting System Magnetic and Metal Detector Sorting System

- Warranty