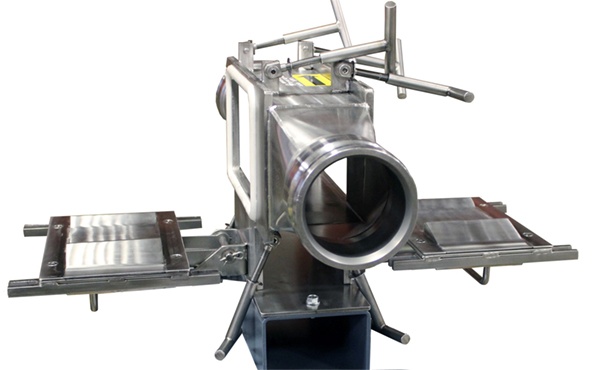

Inline Pneumatic Plate Magnet

Protect Product Purity

MPI’s Inline Pneumatic Plate Magnets are designed for use in gravity-fed chutes and pneumatic conveying systems, which convey low to medium volume product streams. These systems include stainless steel housings with custom connections for installation.

Benefits of the Inline Pneumatic Plate Magnet From Magnetic Products, Inc

- Rugged all-welded construction

- Permanent Ceramic 8 magnet material

- Dust-tight stainless steel construction

- Sanitary hinges & latches

- 1” uniform magnet sealing flanges

- Sani-TIGHT Seal™ Gasket

- Type: Compression style “O-ring” cord gasket

- 100% Positive seal, cannot be over-compressed

- Sanitary: Can be removed for wash-down, no adhesive required

Inline Pneumatic Plate Magnet Product Details

How It Works

The magnetic face consists of (2) 400 grade, stainless steel magnetic poles or steps for maximum holding value. ILPM series plate magnets are easy to install and the magnet’s hinged mount design permits quick, easy cleaning of the magnet’s surface. The strong magnetic field is effective in product streams up to 8” deep. Dual plate magnets configurations are recommended for pneumatic conveying systems.

Product Options

- Powerful rare earth magnet material

- Single & double step magnet face

- Replaceable abrasive resistant face plates

- Hinge mounted “quick-clean“ magnet face

- Self clean units with two pneumatic cylinders

- Food-grade finishes

- USDA finish

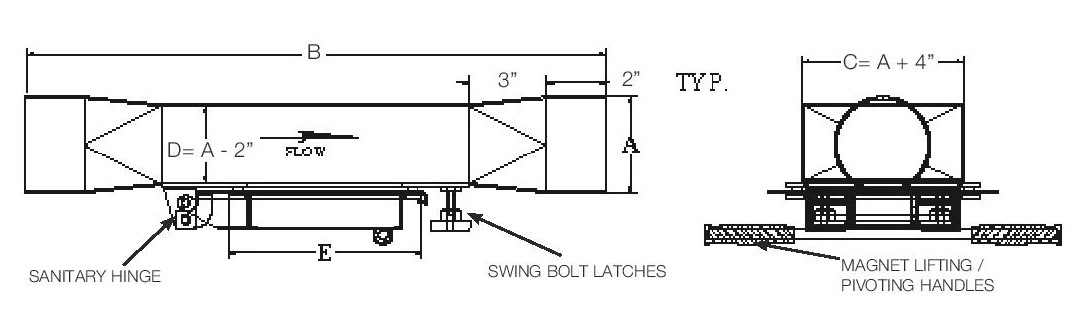

Specifications

US Customary Units

| Model # | Diameter (A) | Overall Length (B) |

|||||

| IN | IN | ||||||

| ILPM-100 | 4 | 5 | 6 | 8 | 10 | 12 | 28.5 |

| ILPM-200 | 4 | 5 | 6 | 8 | 10 | 12 | 28.5 |

| ILPM-300 | 4 | 5 | 6 | 8 | 10 | 12 | 30 |

| ILPM-400 | 4 | 5 | 6 | 8 | 10 | 12 | 32.5 |

| ILPM-500 | 4 | 5 | 6 | 8 | 10 | 12 | 35.5 |

| ILPM-600 | 4 | 5 | 6 | 8 | 10 | 12 | 35.5 |

Metric Units

| Model # | Diameter (A) | Overall Length (B) |

|||||

| MM | MM | ||||||

| ILPM-100 | 101 | 127 | 152 | 203 | 254 | 305 | 724 |

| ILPM-200 | 101 | 127 | 152 | 203 | 254 | 305 | 724 |

| ILPM-300 | 101 | 127 | 152 | 203 | 254 | 305 | 775 |

| ILPM-400 | 101 | 127 | 152 | 203 | 254 | 305 | 825 |

| ILPM-500 | 101 | 127 | 152 | 203 | 254 | 305 | 902 |

| ILPM-600 | 101 | 127 | 152 | 203 | 254 | 305 | 902 |

Diameters highlighted in blue are MPI recommended. The other diameters are not typically recommended though they may fit special needs.