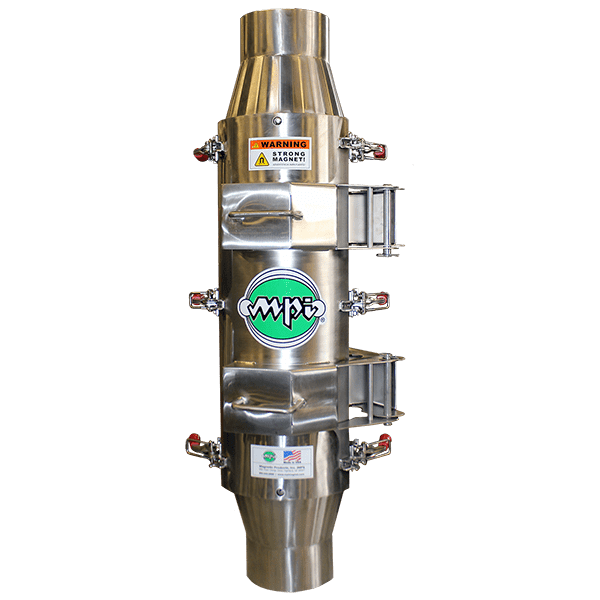

Pneumatic Line Magnet

Commonly Referred to as Bullet Magnet or Torpedo Magnet

Used to remove fine metal contaminants in dilute-phase pneumatic conveying, MPI Pneumatic Line Magnets boast a sanitary design in all product contact areas, quick-release DE-STA-CO clamps for easy opening and closing, 100% stainless steel construction, and powerful Rare Earth magnet material. A new and improved food-grade silicone gasket offers a positive seal which virtually eliminates the need to replace gaskets. MPI provides a seam-welded magnetic stainless steel “raised” pole design that improves tramp metal retention between cleaning as compared to similar units.

Note: Based on their overall shape, these units are commonly referred to as Bullet Magnet style or Torpedo Magnet style.

Benefits of the Pneumatic Line Magnet From Magnetic Products, Inc

- Maximum tramp metal retention:

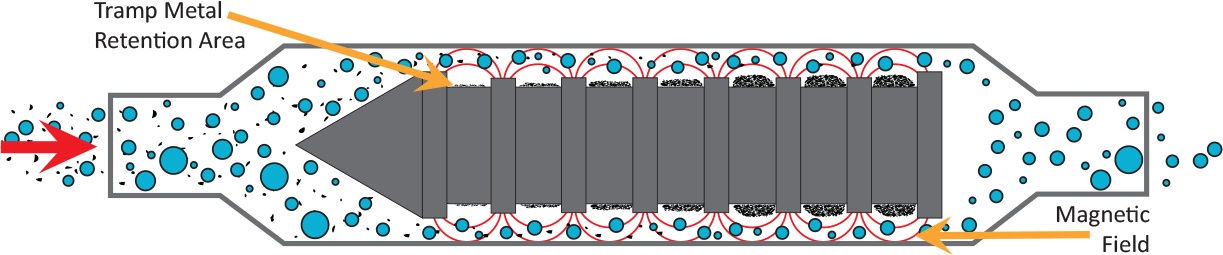

- Seven (7) magnetic poles ensure maximum product exposure to a magnetic field and tramp metal holding surface area

- Poles are raised to ensure that captured tramp metal is retained between cleanings holding it outside of direct product flow eliminating potential “wash off”

- 52-55 MGOe rare earth magnetic cartridge

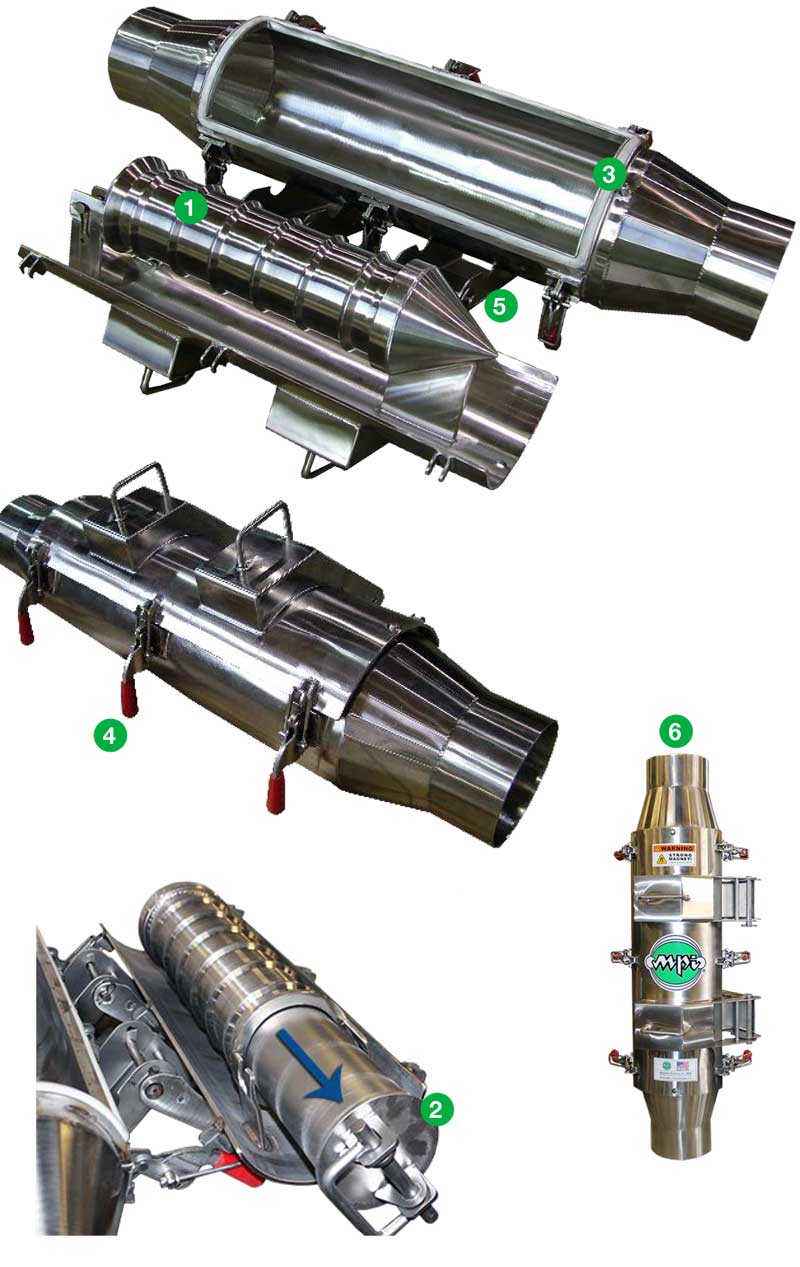

- Easy clean design with removable magnetic core allows the magnet to operate at maximum performance between cleanings. To clean:

- Unlatch clamps, open door and turn magnet 90 degrees

- Pull magnet cartridge towards operator until removed from the housing. With magnet removed, tramp metal will fall onto the housing door for collection.

- Replace magnet cartridge, turn 90 degrees to lock back into place and clamp system closed

- Sani-TIGHT Seal™ Gasket:

- Type: Compression style “O-ring” cord gasket (Optional metal detectable)

- Sealing plate: ½” thick machined stainless channel

- 100% Positive seal, cannot be over-compressed

- Sanitary: Gasket can be removed and replaced for wash-down, no adhesive required

- DE-STA-CO clamps:

- Quick and easy access to inspect and clean magnet

- Maintains positive seal during operation and does not allow for over tightening

Designed for operating pressures of 15 PSI

- Hinged access door:

- Support provides safe and lightweight inspection for operators

- Various cart and connection systems available:

- Available in various cart and connection designs to fit any application

Pneumatic Line Magnet Product Details

How It Works

MPI Pneumatic Line Magnets are easy to install in vertical or horizontal piping. A quick-clean removable magnet element allows for rapid and easy removal of tramp metal. Its raised pole design prevents metal “wash-off” contrary to other smooth surface models. Typical applications include powder or granular food products, pharmaceuticals, plastics and chemicals conveyed at high speeds in low density, high-air systems.

Product Options

- Pipe Size: Available in diameters from 2” to 10” in any increment.

- Cleaning Method:

- Manual clean

- Manual quick-clean with removable magnetic core (standard)

- Magnet Element:

- 7 raised poles (standard on sizes up to 6”)

- 5 raised poles (standard on sizes 7” and larger)

- Material Construction:

- 304 Stainless steel with 430 stainless steel raised poles (standard)

- 316 Stainless steel, including raised poles (reduces pull value on contact compared to 430 stainless poles)

- Magnet Material & Temperature:

- 400°F (204°C) @ 3.5 MGO (ceramic)

- 176°F (80°C) @ 52+ MGOe (rare earth) (standard)

- 248°F (120°C) @ 48 MGO (rare earth)

- 356°F (180°C) @ 38 MGO (rare earth)

- 662°F (350°C) @ 30 MGO (rare earth)

- Gasket Material:

- White silicone, FDA approved (standard)

- Buna, FDA approved

- Metal detectable blue silicone, FDA approved

- Customer specified

- Inlet Flange Design:

- 3” plain end for compression coupling installation (standard)

- Cam Lock: male adapter

- Cam Lock: female adapter

- ANSI 150-pound flange

- Customer specified

- Outlet Flange Design:

- 3” plain end for compression coupling installation (standard)

- Cam Lock: male adapter

- Cam Lock: female adapter

- ANSI 150-pound flange

- Customer specified

- Position Switch: For unit closed confirmation or safety interlock

- Not included (standard)

- Proximity switch for unit closed confirmation (MPI Standard model and mount)

- Mechanical safety switch for unit closed confirmation and safety (MPI Standard model and mount)

- Switch mounting bracket only (customer supplied switch)

- Customer specified model

- Cart: MPI can provide a cart for the separator so it can be transported easily, commonly used for bulk unloading and/or loading areas.

- Not included (standard)

- Included

Specifications

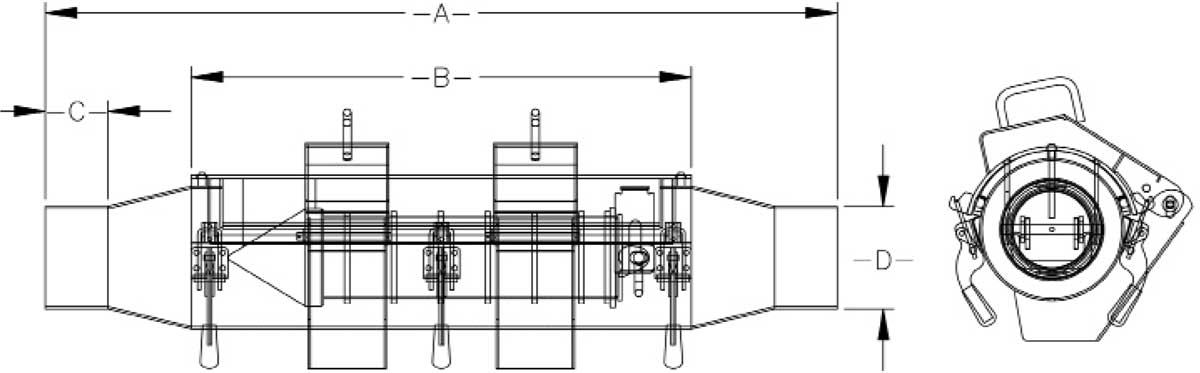

US Customary Units

| Model # | Overall Length (A) |

Door Length (B) |

Tube Length (C) |

Tube Diameter (D) |

Approx. Unit Weight |

| IN | IN | IN | IN | LBS | |

| PLM-3-REN-QC | 38 | 24 | 3 | 3 | 85 |

| PLM-4-REN-QC | 38 | 24 | 3 | 4 | 88 |

| PLM-5-REN-QC | 38 | 24 | 3 | 5 | 92 |

| PLM-6-REN-QC | 38 | 24 | 3 | 6 | 98 |

| PLM-7-REN-QC | 38 | 24 | 3 | 7 | 137 |

| PLM-8-REN-QC | 50 | 36 | 4.5 | 8 | 170 |

Metric Units

| Model # | Overall Length (A) |

Door Length (B) |

Tube Length (C) |

Tube Diameter (D) |

Approx. Unit Weight |

| MM | MM | MM | MM | KG | |

| PLM-3-REN-QC | 965 | 610 | 76 | 76 | 39 |

| PLM-4-REN-QC | 965 | 610 | 76 | 102 | 40 |

| PLM-5-REN-QC | 965 | 610 | 76 | 127 | 42 |

| PLM-6-REN-QC | 965 | 610 | 76 | 152 | 44 |

| PLM-7-REN-QC | 965 | 610 | 76 | 178 | 62 |

| PLM-8-REN-QC | 1270 | 914 | 114 | 203 | 77 |