Sheet Separator

Improve Productivity and Employee Safety

MPI sheet separators are designed to improve productivity and employee safety in sheet handling operations. These magnets can also provide significant benefits in reducing costs by eliminating “doubles” when handling oily, sticky, or prefinished sheet stock in an automated stamping, forming, or blanking operation. Sheet separators utilize the basic laws of magnetic “like poles” repelling characteristics in their use and operation. By inducing “like” magnetic fields into a stack of steel sheets or plates, repelling forces are created from sheet to sheet, forcing them to separate from each other.

Benefits of the Sheet Separator From Magnetic Products, Inc

- Rugged all-welded construction

- Powerful Ceramic 8 Permanent magnet material

- 100% Stainless Steel housing

Sheet Separator Product Details

How It Works

SS-Series Sheet Separators utilize the basic laws of magnetic “like poles” repelling characteristics in their use and operation. By inducing “like” magnetic fields into a stack of steel sheets or plates, repelling forces are created from sheet to sheet, forcing them to separate from each other.

- Rugged all-welded construction

- Ceramic 8 magnet material

- 100% Stainless Steel housing

Product Options

- Special mounting brackets

- Removable wear strips

- Optional sizes

- Powerful Rare Earth magnet material

Specifications

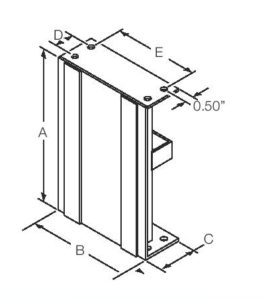

| Four series of Standard Sheet Separators, each with their own specific advantages, so you can create a design solution that fits your application needs and still save you money. It is recommended that the sheet separator be at least 2 inches taller than the stacked steel height, for optimum operation. |  |

US Customary Units

| Sheet Size (Inches) |

Sheet Metal Thickness | |||

| 22 Gage | 16 Gage | 11 Gage | 1/4″ Plate | |

| 6 x 12 | Use SS-600 | Use SS-600 | Use SS-800 | Use SS-800 |

| 12 x 12 | Use SS-600 | Use SS-800 | Use SS-800 | Use SS-800 |

| 12 x 24 | Use SS-600 | Use SS-1000 | Use SS-1000 | Use SS-1200 |

| 24 x 24 | Use SS-800 | Use SS-1000 | Use SS-1000 | Use SS-1200 |

| 24 x 36 | Use SS-800 | Use SS-1200 | Use SS-1200 | Use SS-1200 |

| 36 x 36 | Use SS-800 | Use SS-1200 | Use SS-1200 | Use (2) SS-1200 |

| 600 Series Sheet Separator | ||

| Model # | Height (A) | Width (B) |

| IN | IN | |

| SS-605 | 5 | 6 |

| SS-609 | 9 | 6 |

| SS-612 | 12 | 6 |

| SS-618 | 18 | 6 |

| 800 Series Sheet Separator | ||

| Model # | Height | Width |

| IN | IN | |

| SS-809 | 9 | 8 |

| SS-812 | 12 | 8 |

| SS-818 | 18 | 8 |

| SS-824 | 24 | 8 |

| 1000 Series Sheet Separator | ||

| Model # | Height (A) | Width (B) |

| IN | IN | |

| SS-1009 | 9 | 10 |

| SS-1012 | 12 | 10 |

| SS-1018 | 18 | 10 |

| SS-1024 | 24 | 10 |

| 1200 Series Sheet Separator | ||

| Model # | Height (A) | Width (B) |

| IN | IN | |

| SS-1209 | 9 | 12 |

| SS-1212 | 12 | 12 |

| SS-1218 | 18 | 12 |

| SS-1224 | 24 | 12 |

Metric Units

| Sheet Size (CM) |

Sheet Metal Thickness | |||

| 22 Gage | 16 Gage | 11 Gage | 6.4mm Plate | |

| 15.2 x 30.5 | Use SS-600 | Use SS-600 | Use SS-800 | Use SS-800 |

| 30.5 x 30.5 | Use SS-600 | Use SS-800 | Use SS-800 | Use SS-800 |

| 30.5 x 61 | Use SS-600 | Use SS-1000 | Use SS-1000 | Use SS-1200 |

| 61 x 61 | Use SS-800 | Use SS-1000 | Use SS-1000 | Use SS-1200 |

| 61 x 91.4 | Use SS-800 | Use SS-1200 | Use SS-1200 | Use SS-1200 |

| 91.4 x 91.4 | Use SS-800 | Use SS-1200 | Use SS-1200 | Use (2) SS-1200 |

| 600 Series Sheet Separator | ||

| Model # | Height (A) | Width (B) |

| MM | MM | |

| SS-605 | 127 | 152 |

| SS-609 | 229 | 152 |

| SS-612 | 395 | 152 |

| SS-618 | 457 | 152 |

| 800 Series Sheet Separator | ||

| Model # | Height | Width |

| MM | MM | |

| SS-809 | 229 | 203 |

| SS-812 | 305 | 203 |

| SS-818 | 457 | 203 |

| SS-824 | 610 | 203 |

| 1000 Series Sheet Separator | ||

| Model # | Height (A) | Width (B) |

| CM | CM | |

| SS-1009 | 229 | 254 |

| SS-1012 | 395 | 254 |

| SS-1018 | 457 | 254 |

| SS-1024 | 610 | 254 |

| 1200 Series Sheet Separator | ||

| Model # | Height (A) | Width (B) |

| MM | MM | |

| SS-1209 | 229 | 304 |

| SS-1212 | 305 | 304 |

| SS-1218 | 457 | 304 |

| SS-1224 | 610 | 304 |