Battery Lifting Magnet BMP

Versatile Workplace Tool

The MPI Battery Lifting Magnet BMP series feature a pole shape to handle round, angle sheet piles and flat materials – tubes, bars, I-, H- T- and Z shaped profile sections. The MPI BMP Battery Lifting Magnet, complete with remote control, is an ideal tool for handling situations where it is difficult to manually operate a lifting device. The versatility of the battery-powered lifting magnet makes it an essential workshop tool for steel stockist receiving and shipping areas, and accessories of transportation cranes, burning tables, machine tools, and/or sawing applications.

The BMP model manages flat loads from 3,968 lbs. to 7,936 lbs. and round loads from 2,425 lbs. to 4,850 lbs. which make the lifters capable of handling big format steel sheets, heavy blocks, various flame cuts, machine components, smooth castings or forgings.

All BMP battery-powered lifting magnets offer the highest level of safety. The synoptic display with battery level LED indicator features shutdown blocking during the lifting process (lifting eye sensor) plus audible and visual warning signals to indicate a low battery level. A user engages the lifter by the controls on the magnet body or the IR remote control from up to 33’ away.

All BMP battery powered lifting magnets are self-contained with a battery capacity of at least eight hours of operation (with 50% duty cycle). MPI’s BM series feature Variable Force and Tip-Off functions. This serves as a universal tool for handling various steel plates – thinner or thicker, single or multiple at once with subsequent dropping. Controllable force is convenient for picking up thin metal sheet from metal supports such as machine tables, pallets, benches etc.

Benefits of the Battery Lifting Magnet BMP From Magnetic Products, Inc

- Universal large steel lifting eye with safety bail sensor makes it impossible to disengage magnet during lifting

- Compact LED safety display with battery status indicator provides audio and visual warning of low battery level – magnet will not activate once the battery voltage drops below the safety level lifting

- Pole shape makes it possible to handle round, angle sheet piles and flat materials – tubes, bars, I-, H- T- and Z shaped profile sections

- Powered by built-in 12V battery – includes battery charger, battery and remote

- IR remote controller operates from up to 33’ to handle loads with poor accessibility to stay clear of dangerous situations

- Variable Force adjusts holding force when handling a particular quantity of sheet-metals from a stack – magnetic field strong enough for loads with variable, uneven surfaces and air gaps

- One (1) year warranty for the magnetic system

- Manufactured in Europe to the highest quality standards

- Meets all the requirements of ANSI/ASME B30.20 (safety standard)

Battery Lifting Magnet BMP Product Details

How It Works

Our MPI Battery-Powered Lifting Magnets (BMP) are a series of lifting magnets with a built-in battery power supply and high lifting capacities. The magnet is conformable with a safety factor of 2:1, i.e. it can carry more than double its maximum allowed lifting capacity in the tear-away test. Power is provided by a 12V built-in battery allowing up to eight hours of operating time at 50% duty cycle also included is a remote control allowing safe operation up to 33′ away. There is a safety switch under the lifting eye to prevent switching off during lifting. It is not possible to activate the magnet once the battery voltage drops below the safety level. Additionally, low battery is indicated by visual and audible alarms.

Product Options

Currently no options available for this product.

Specifications

When to choose battery-powered MPI Lifting Magnet BMP:

The MPI Battery Lifting Magnet BMP series feature a pole shape to handle round, angle sheet piles and flat materials – tubes, bars, I-, H- T- and Z shaped profile sections. The BMP, complete with remote control, is an ideal tool for handling situations where it is difficult to manually operate a lifting device. The BMP model manages flat loads from 3,968 lbs. to 7,936 lbs. and round loads from 2,425 lbs. to 4,850 lbs. which make the lifters capable of handling big format steel sheets, heavy blocks, various flame cuts, machine components, smooth castings or forgings.

Download the Lifting Magnet Workload Limit Instructions.

|

|

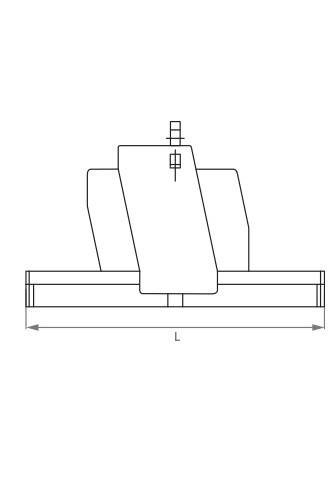

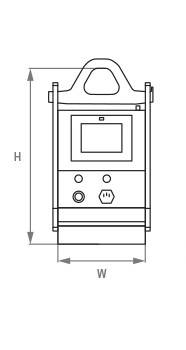

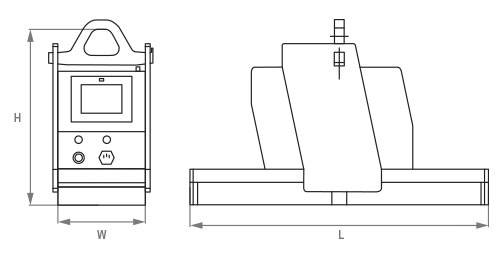

US Customary Units

| Part Number | Lifting Capacity for Flat Materials (LBS) | Lifting Capacity for Round Materials (LBS) | Minimum/Maximum Diameter (IN) | Testing Lifting Capacity LBS) | W x L of Base IN) | Height up to Crane Hook (IN) | Weight (LBS) | Built in Battery | |

| BMP-3968 | 3,968 | 2,425 | 1.57/17.32 | 7,936 | 9.5 x 18.5 | 24 | 368 | 12V/75Ah | |

| BMP-7936 | 7,936 | 4,850 | 1.77/19.69 | 15,873 | 10.3×30 | 24 | 926 | 12V/75Ah |

Metric Units

| Part Number | Lifting Capacity for Flat Materials (kg) | Lifting Capacity for Round Materials (kg) | Minimum/Maximum Diameter (mm) | Testing Lifting Capacity (lbs) | W x L of Base (mm) | Height up to Crane Hook (mm) | Weight (kg) | Built in Battery | |

| BMP-3968 | 1,800 | 1,100 | 40/440 | 3,600 | 241 x 470 | 610 | 167 | 12V/75Ah | |

| BMP-7936 | 3,600 | 2,200 | 45/500 | 7,200 | 262 x 760 | 610 | 420 | 12V/75Ah |

Related Resources

Locate a Distributor

|

Distributor Name |

Distributor | Product Part Number | Product Link |

| BMP-3968 |  |

BMP-3968 | https://www.mscdirect.com/product/details/14505333 |

| BMP-3968 |  |

BMP-3968 | https://www.penntoolco.com/mpi-battery-powered-lifting-magnet-bmp-3-968-lbs-lifting-capacity-flat-material-bmp-3968/ |

| BMP-7936 |  |

BMP-7936 | https://www.mscdirect.com/product/details/14504567?orderedAs=BMP-7936&pxno=75370049 |

| BMP-7936 |  |

BMP-7936 | https://www.penntoolco.com/mpi-battery-powered-lifting-magnet-bmp-7-936-lbs-lifting-capacity-flat-material-bmp-7936/ |