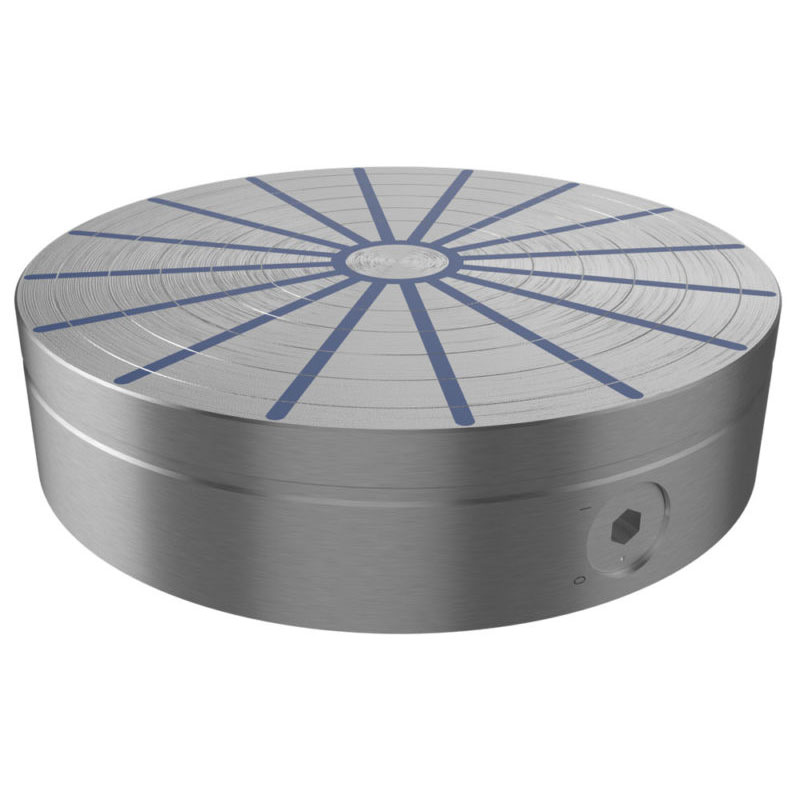

Double Rare Earth Round Chuck

Achieve More Efficient Machining

The MPI Double Rare Earth Round Chuck is primarily designed for turning and grinding round and ring-shaped workpieces. The top plate with radial poles offers the possibility to machine the front, inner and outer diameter of the workpiece in one operation.

Benefits of the Double Rare Earth Round Chuck From Magnetic Products, Inc

- Compact top plate made of one piece of steel with radial poles

- Very powerful double magnetic system with neodymium magnets

- Regrind limit: 0.20in

- Suitable for turning and circular grinding

- Steel base

- One (1) year warranty for the magnetic system

- Manufactured in Europe to the highest quality standards

- Included with Each Magnet: Allen Key and instructions for use

- Optional: Auxiliary top plate and Top plate with T-slots

Double Rare Earth Round Chuck Product Details

How It Works

Due to the top plate with radial poles, the MPI Double Rare Earth permanent chuck is primarily designed for turning and grinding round and ring-shaped workpieces. The advantage is the possibility to machine the front, inner and outer diameter of the workpiece in one operation.

Product Options

Drive System: Patented M-10000 Series shaker drive system module including motor, gear case and cam mounted to base plate to drive system, as configured below.

Assembled Pan Length: The maximum length of the shaker pan is dependent on the size, shape, material, and scrap rate being transferred on the pan. Below are general guidelines for maximum lengths.

- Up to 250 ft. based on pan width of 24”

- Up to 200 ft. based on pan width of 36”

Pan Size: Pan sizes and shapes can be configured for the application as required. Below are the standard shaker pan sizes and shapes available. Overall pan section / width of the system is pan width + 8”. MPI recommends an OSHA compliant 18” walkway on one side of the shaker pan system. Minimum recommended pit width = pan width + 8” + 18”. Note that drive section will always require a minimum 48” width.

- Troughed pan shape 24” wide pan x 6” deep

- Troughed pan shape 24” wide pan x 12” deep

- Troughed pan shape 36” wide pan x 6” deep

- Troughed pan shape 36” wide pan x 12” deep

- Rectangular pan shape 24” wide x 6” tall side guides for low profile installation

- Rectangular pan shape 36” wide x 6” tall side guides for low profile installation

- Custom pan shape as required for application

Pan Material: MPI offers different pan materials and configurations to ensure reliable scrap transfer rates and abrasion resistance as required by the application.

- Manufactured from 10-gauge carbon steel (standard)

- Manufactured from 10-gauge stainless steel

- Manufactured from 7-gauge manganese steel for increased impact and wear resistance

- Manufactured from 10-gauge carbon steel with replaceable wear liner manufactured from optional material such as rigidized sheet, AR sheet or composite materials as required for the application

Bearings: Bearings support the shaker pan and are installed on the top and bottom of a support arm that connects at the pan and subframe. Maintenance free Rubber Suspension Technology (RST) bearings (included).

Conveyor Speed: The horizontal motion of the conveyor system has a maximum design speed but can run at lower speeds if needed. Maximum design speed is 15 FPM.

Pan Height: Shaker conveyor pan height is flexible based on the configuration required and stack-up height of multiple systems.

- 22” complete with subframe (standard)

- Low profile custom design without subframe available

- Raised pan height to accommodate customer specified pan height with additional subframe supports

Motor Installation Location: MPI offers multiple drive motor installation locations for flexibility of installation into existing plants.

Motor: Motor horsepower ratings are sized for the application and available in multiple input voltages as required by the installation location.

Grease System: Installed on main drive for maintenance free lubrication.

- 2-year auto lube grease pack to reduce maintenance requirements

Paint:

- Carbon steel components painted MPI Green, guards paint safety yellow (standard)

- Carbon steel components painted grey, guards paint safety yellow

- Customer specified color, RAL # required

Controls: MPI offers standard control packages for the shaker system. Controls can be customized if required for the application.

Safety Devices: For added safety, MPI recommends installing an E-stop pull cord system around the accessible sides of the shaker system.

Motion Control Monitoring: Motion control systems are integrated into the control system to ensure movement to the shaker system.

Specifications

When to choose the MPI Double Rare Earth Round Chuck:

The MPI Double Rare Earth Round Chuck is primarily designed for turning and grinding round and ring-shaped workpieces. The top plate with radial poles offers the possibility to machine the front, inner and outer diameter of the workpiece in one operation.

Important parameters:

- Application: Turning

- Technology: Permanent

- Chuck dimensions: from 5in

- Holding force: 140N/cm² / 203lbs/in²

- Minimum workpiece limit: 35mm / 1.377”

- Regrinding limit: 0.2 in

- Poles: Radial

Use:

- turning and grinding of round and ring-shaped workpieces

- facing work, internal and external diameter machining is possible separately or in one operation

US Customary Units

| Part Number | D | H | D1 | E | F | Weight | |

| IN | IN | IN | IN | IN | LBS | ||

| RC-130-REN | 5 | 2.2 | 0.59 | – | 3.9 | 11 | |

| RC-150-REN | 6 | 2.2 | 0.59 | 3.15 | 4.7 | 16 | |

| RC-200-REN | 8 | 2.2 | 0.787 | 4.33 | 7.1 | 29 | |

| RC-250-REN | 10 | 2.8 | 1.18 | 5.51 | 8.7 | 55 | |

| RC-300-REN | 12 | 2.9 | 1.49 | 7.09 | 10.24 | 82 | |

| RC-350-REN | 14 | 2.9 | 1.57 | 8.66 | 11.81 | 108.03 | |

| RC-400-REN | 16 | 3 | 1.57 | 10.24 | 13.39 | 149.91 | |

| RC-500-REN | 20 | 3 | 1.96 | 11.81 | 15.75 | 240.30 | |

| RC-600-REN | 24 | 3 | 3.54 | 13.78 | 17.72 | 379.20 | |

| RC-700-REN | 28 | 3 | 3.54 | 13.78 | 17.72 | 515.88 | |

| RC-800-REN | 32 | 4.3 | 3.93 | 15.75 | 27.56 | 925.94 |

Metric Units

| Part Number | D | H | D1 | E | F | Weight | |

| MM | MM | MM | MM | MM | KG | ||

| RC-130-REN | 130 | 57 | 15 | – | 100 | 5 | |

| RC-150-REN | 150 | 57 | 15 | 80 | 120 | 7.3 | |

| RC-200-REN | 203 | 57 | 20 | 110 | 180 | 13 | |

| RC-250-REN | 250 | 70 | 30 | 140 | 220 | 25 | |

| RC-300-REN | 300 | 73 | 38 | 180 | 260 | 37 | |

| RC-350-REN | 350 | 73 | 40 | 220 | 300 | 49 | |

| RC-400-REN | 400 | 74 | 40 | 260 | 340 | 68 | |

| RC-500-REN | 500 | 78 | 50 | 300 | 400 | 109 | |

| RC-600-REN | 600 | 78 | 90 | 350 | 450 | 172 | |

| RC-700-REN | 700 | 78 | 90 | 350 | 450 | 234 | |

| RC-800-REN | 800 | 110 | 100 | 400 | 700 | 420 |