Packaged Goods (BD) Detector

Extreme Equipment Sensitivity

The METAL SHARK® Belt Style Metal Detector is often used to detect contaminants in meat, poultry and seafood. Typically integrated onto a conveyor belt, the METAL SHARK® BD readily adjusts settings to ensure extreme equipment sensitivity, stability and reliability. A variety of reject mechanisms (pusher, belt stop, alarm, etc.) are available to alert operators of a “find” or to divert contaminated product. The conveyor belt, framing and controls are available in sanitary design for food grade process applications. Metal Detectors can be easily adjusted to accommodate multi-system processing and environmental product effect changes. Metal detectors offer the latest features in metal detector design to deliver the highest performance systems for your process, reducing the risk of product contamination and protecting your brand. We stand behind our products and offer this satisfaction guarantee – put simply, the unit will perform as specified or we will take it back for a full refund.

Benefits of the Packaged Goods (BD) Detector From Magnetic Products, Inc

- Intuitive Design

- Multiple languages available

- Four-level password: operator, manager, technician and service

- Easy-to-follow, step-by-step, high-graphic screens help users set standards for product testing

- Simple operation means no expensive service calls to adjust settings

- Four Quadrant Technology

- 360° analysis of the product signature

- Metal threshold follows the signature so metal detection occurs in the whole product

- The detector adjusts settings to detect metals in the most “difficult” products such as cheese or high salt content foods

- Zero Maintenance Electronics

- All-solid-state electronics housed on one mainboard – ensures years of reliable performance offering the lowest cost of ownership on the market

- Digital Balance Control adjusts for temperature and humidity fluctuations by monitoring coil balance more than 200 times per second

- 2-year standard warranty

- Documentation and Traceability

Metal detectors are considered a critical control point, and continuous checking is required to meet standards. Cassel metal detectors can be programmed to automatically remind the operator to test equipment performance at pre-set intervals. A list of metal contaminant detections, changes in parameter settings, etc., is stored with both date and time. This list can be viewed on-screen or the data can be downloaded to a Windows-based PC.- Performance validation system (PVS) automatically prompts the operator to test Metal Detector performance at pre-set intervals

- Operational history: events are recorded with the date and time and can be viewed on the control panel or export the log via a serial port

- Data will not be lost during a power outage

Packaged Goods (BD) Detector Product Details

How It Works

- HACCP and IFS Compliance

- Per HACCP principles, Metal Detectors are classified as critical control points and continuous checking is required to meet standards. If requested, Cassel can add a performance validation system (PVS) which automatically prompts the operator to test Metal Detector performance at pre-set intervals.

- Zero Maintenance Electronics

- All-solid-state electronics housed on one mainboard – ensures years of reliable performance offering the lowest cost of ownership on the market. Digital Balance Control adjusts for temperature and humidity fluctuations by monitoring coil balance more than 200 times per second. Cassel units also come with a 2-year standard warranty.

- Operational History

- Metal contaminant event or history, metal report, changes in parameter settings and other events are recorded with the date and time. Users can view the list of “incidents” on the control panel or export the log via a serial port.

- Ready for SHARKNET® Software

- To comply with HACCP and IFS standards, SHARKNET® enables automatic downloading of data documentation to a Windows-based PC.

Product Options

- SHARKNET® software

- Monitor real-time inspection results and actively manage product inspection equipment from a central computer

- Enables automatic downloading of data documentation to a Windows-based PC

- Support required compliance with: HACCP-SQF 2000-BRC-GMP-IFS5-FSSC 22000/PAS 220

- Remote maintenance capability by operators and Cassel technicians

- All data is stored in an SQL database for easy export or integration if needed

- Low-pressure wash-down (IP67)

- METAL SHARK® controller is be housed in a double-thick stainless steel enclosure

- Can be washed down with a pressure hose

- High-pressure wash-down (IP69k)

- Aperture is specially sealed to prevent leaks

- METAL SHARK® controller is housed in a double-thick stainless steel enclosure

- Daily wash-ups with a steam hose at a maximum pressure of 60 bar/900 psi can be conducted

- Sausage processors and other manufacturers who conduct frequent wash-ups have found this feature very beneficial

Specifications

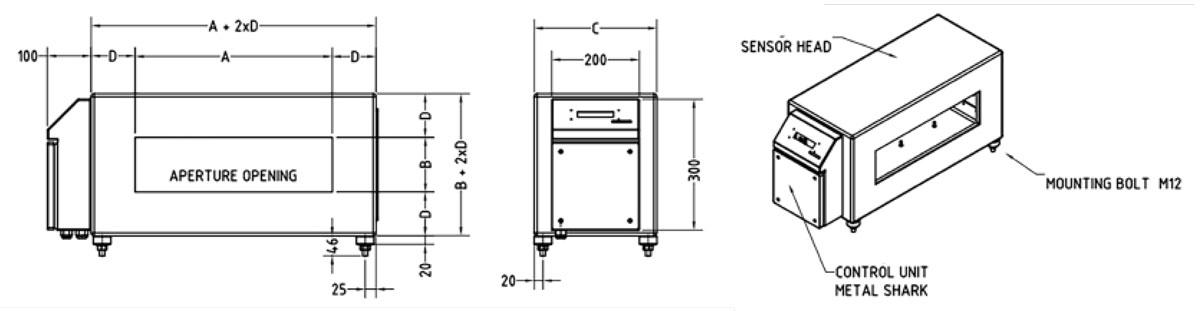

| MD-BD Model | Metal Detector for Conveyor Installations |

| Housing | Stainless steel |

| Control Electronics | Digital signal processor, digital noise filter, digital balance control, digital frequency control with a synthesizer, digital temperature shift control, continuous self-monitoring, maintenance-free, no need for calibration, PowerDrive circuit |

| Output Signal | Metal alarm with potential-free changeover contact, metal alarm for 24V DC SPS activation, metal alarm for activation of 24V pusher magnetic valve, operating state/disturbance with potential-free changeover contact (230V/5 A), performance validation upon request, visual and acoustic alarm |

| Input Signal | All 24V DC reject trigger, e.g., photosensor, monitoring of compressed air, reject affirmation, metal alarm confirmation, keyboard interlock, conveyor belt control, change of product, teaching mode |

| Measuring Method | Inductive, multi-channel operation, balanced receiver coil |

| Metal Detention | Ferrous, nonferrous (e.g., aluminum or copper) and stainless steel |

| Product Library | 120 storage spaces |

| Product Compensation | Performed automatically with a teaching mode |

| Ambiance | Temperature -10 to +50 degrees C, humidity 30 to 85% |

| Product Temperature | -30 degrees C to +80 degrees C |

| Power Supply | One phase 85 – 264V AC, 50/60 Hz, 100 watt |

| Interface | RS232, RS485, provides documentation per HACCP and IFS standards |