Compact Gravity Feed Metal Detector

Highest Performance Technology

For free falling powder and bulk products. Gravity feed type metal detectors are used in gravity feed pipes and provide the highest performance in detecting magnetic and non-magnetic metals. The bulk material falls through the metal detector. With the reject flap, even the smallest metal objects are separated out of the product stream promptly. The GF Compact has a low assembly height and is specially designed for limited space applications. Due to the ultra-compact sensor head, the metal detection performance is slightly lower compared to the full-size model.

Benefits of the Gravity Feed Compact Metal Detector From Magnetic Products, Inc

- Full 2 year warranty on complete system–giving you peace of mind

- Hygienic food industry design-ensures compliance with good manufacturing principles

- Harsh environment rating as standard on sensor head–ensures the unit remains stable whatever the environment

- Semi-flexible aperture lining–resists thermal shock due to temperature change and protects the sensor for maximum operating life and minimum down time

- All solid state electronics housed on one main board–ensures years of reliable performance offering the lowest cost of ownership on the market

- Intuitive menu structure–simple operation for reliable performance, no expensive service calls to adjust settings

- Full HACCP compliance–demonstrates your due diligence, ensures you and your customers are protected

- Full pre-sale applications and custom design service–making sure we provide the right solution first time

- Satisfaction guarantee–put simply, the unit will perform as specified or we will take it back for a full refund

Gravity Feed Compact Metal Detector Product Details

How It Works

Once installed in a gravity feed pipeline, bulk material falls through the metal detector. If any metallic contaminant, magnetic or non-magnetic is detected, the reject flap engages to promptly separate and exit the contaminant from the product stream.

Gravity Feed Metal Detector

For free falling powder and bulk products.

Once installed in a gravity feed pipeline, bulk material falls through the metal detector. If any metallic contaminant, magnetic or non-magnetic is detected, the reject flap engages to promptly separate and exit the contaminant from the product stream.

METAL SHARK® Gravity Feed (GF) Metal Detectors, available in both standard and compact models, are used in gravity feed pipelines to monitor for unwanted metal contaminants in continuous flowing granules or powders, such as sugar, flour, cornmeal, and spices.

Product touching parts are made according to FDA food-grade quality standards. As bulk material flows through the metal detector, reject flaps promptly separate even the smallest metal contaminants from the product stream.

Maintenance-free design and high-quality construction ensure reliable operation in the most challenging industrial environments. Pipe diameters are available from 1/2″ to 24″. ATEX Zone 21 and 22 versions are available.

The Metal Detector GF is commonly used for:

- Powdered milk

- Sugar

- Cereal

- Proteins

- Spices

- Granules

The Metal Detector GF is enclosed in 100% stainless steel housing and is specifically designed for use in the food industry.

Available digital controller: METAL SHARK® 2A

Features & Benefits of Metal Detector GF

Compact design: The Metal Detector GF boasts the industry′s shortest installation height.

A mounting frame with an integrated metal-free zone allows for exceptionally quick and easy installation.

Sturdy design: A rock-solid sensor head and mounting frame design ensure consistent reliability and performance. The METAL SHARK® Gravity Feed can be located even near machines that vibrate.

Multiple reject options: The EX-P reject system with dust sealing is recommended for powders. The EX-S reject system is best suited for applications with fast-flowing products. The EX-K reject system is built to withstand the challenges of abrasive products and will not wear out.

Various downpipe types: white PVDF (with FDA), black antistatic pipes (with FDA), nylon, ceramic and others.

Product Options

- SHARKNET® software

- Monitor real-time inspection results and actively manage product inspection equipment from a central computer

- Enables automatic downloading of data documentation to a Windows-based PC

- Support required compliance with: HACCP-SQF 2000-BRC-GMP-IFS5-FSSC 22000/PAS 220

- Remote maintenance capability by operators and Cassel technicians

- All data is stored in an SQL database for easy export or integration if needed

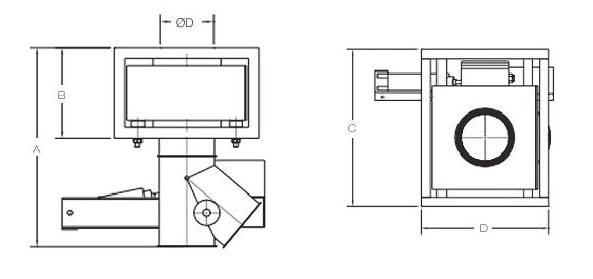

Specifications

Gravity Feed Compact MD Model

US Customary Units

| Model # |

Flow Opening (OD) |

Overall Height (A) |

MD Height (B) |

MD Width (C) |

MD Depth (D) |

Typical Material Flow |

Approximate Sensitivity (mm) | ||

| IN | IN | IN | IN | IN | FT3/HR | FE | AI | SS | |

| GF0100C | 4 | 17.7 | 7.9 | 17.7 | 12.5 | 700 | 0.7 | 1.0 | 1.1 |

| GF0120C | 5 | 20.9 | 9.8 | 17.7 | 13.3 | 1000 | 1.0 | 1.2 | 1.4 |

| GF0150C | 6 | 23.6 | 9.8 | 19.8 | 15.8 | 1500 | 1.1 | 1.5 | 1.8 |

| GF0200C | 8 | 35.8 | 11.8 | 24.2 | 20 | 2600 | 1.6 | 2.2 | 2.4 |

| GF0250C | 10 | 41.3 | 15.4 | 31.5 | 26 | 4000 | 2.0 | 2.7 | 3.1 |

| GF0300C | 12 | 43.1 | 15.4 | 37 | 31.5 | 5800 | 2.6 | 3.2 | 4.1 |

Metric Units

| Model # |

Flow Opening (OD) |

Overall Height (A) |

MD Height (B) |

MD Width (C) |

MD Depth (D) |

Typical Material Flow |

Approximate Sensitivity (mm) | ||

| MM | MM | MM | MM | MM | M3/HR | FE | AI | SS | |

| GF0100C | 100 | 450 | 200 | 450 | 318 | 19.8 | 0.7 | 1.0 | 1.1 |

| GF0120C | 120 | 530 | 250 | 450 | 338 | 28.3 | 1.0 | 1.2 | 1.4 |

| GF0150C | 150 | 600 | 250 | 502 | 400 | 42.5 | 1.1 | 1.5 | 1.8 |

| GF0200C | 200 | 910 | 300 | 615 | 508 | 73.6 | 1.6 | 2.2 | 2.4 |

| GF0250C | 250 | 1050 | 390 | 800 | 641 | 113.3 | 2.0 | 2.7 | 3.1 |

| GF0300C | 300 | 1095 | 390 | 940 | 800 | 164.2 | 2.6 | 3.2 | 4.1 |