Protecting and Moving the World Through Innovation

Protecting and Moving the World Through Innovation

Shakers | Radar Industries

MPI Electric Shakers Stamp Out Downtime

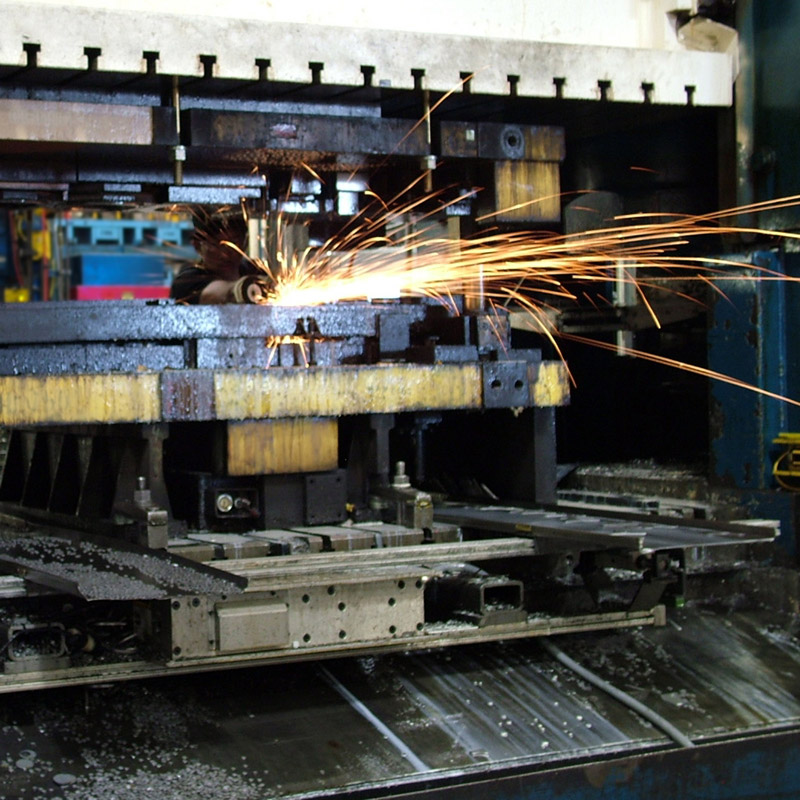

Like any maintenance supervisor at a busy stamping plant, 30-year manufacturing veteran Mike DeWitt’s goal at Radar Industries in Warren, Michigan, is to keep his presses up and running. With per-press downtime costing $250 – $1000 an hour, keeping production running is critical to profitability. So, when the pneumatic shakers used to move scrap away from Radar’s presses began to cause downtimes of 50% – 60% per shift, DeWitt knew he needed a better equipment solution.

“The reliability of the pneumatic shakers was horrendous,” explained DeWitt. “I was faced with mounting downtime costs and mountains of scrap.”

As Radar explored new options, one of MPI’s Regional Sales Managers visited Radar’s Warren plant and listened to DeWitt’s concerns. MPI suggested the electric shaker. DeWitt was immediately impressed by its design and the shaker was lent to Radar Industries.

It wasn’t long before DeWitt retrofitted an MPI electric shaker on each of the 17 presses in Radar’s Michigan and Mexico plants. “The electric shakers totally eliminated the downtime issue and slashed the costs caused by our old pneumatics.”

Unlike pneumatic shakers, MPI’s patent-pending electric shakers require no maintenance, produce little noise, and perform reliably — even under the harshest factory conditions. They do not rely on costly plant air, resulting in less expensive operation. MPI electric shakers are green, they handle low-to-very-heavy (10,000 pounds) scrap volumes, and they leave the factory floor ready to fit nearly all press bed T-slot configurations.

“These shakers have done everything that has been asked of them and then some.”

Radar Industries deals with scrap of varying sizes and shapes, making it difficult to find one system that solves the overall scrap issue. But, according to DeWitt, MPI’s electric shakers handle nearly everything. “The electric shakers are nearly as maintenance-free as any equipment could be. We inspect them periodically to make sure scrap isn’t jammed. Other than that, there really isn’t any maintenance.”

“The better my presses operate, the more scrap they produce,” said DeWitt. And his presses produce a lot of it — some 2000 pounds of scrap per hour. “These shakers have done everything that has been asked of them and then some.”

These days, when DeWitt arrives at Radar Industries, he knows that his scrap-removal problem has been permanently solved. With MPI’s electric shakers in place, the presses keep on running and downtime is now a rare concern.