Protecting and Moving the World Through Innovation

Protecting and Moving the World Through Innovation

Shakers | Toledo Tool & Die

MPI Electric Shaker

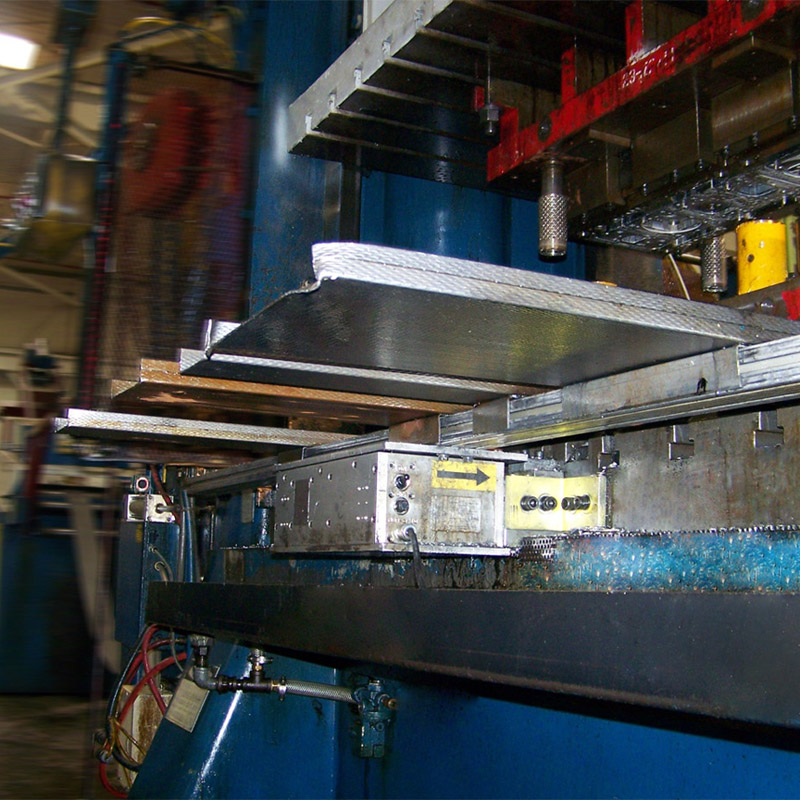

Toledo Tool and Die (TTD), of Toledo OH, approached MPI looking for an improved method to remove scrap from their stamping press. MPI recommended that TTD consider MPI’s M-50 electric shaker. The M-50 is maintenance free and runs on simple, plug-and-play 120 vac. Moreover, the M-50 runs at less than .5 amp draw, making it the most economical shaker in the world to operate.

MPI loaned TDD an M-50 for a free trial in its facility. Once in place, TDD staff quickly realized that the M-50 was the perfect solution and determined that several more units were needed immediately.

TTD had been using air-powered shakers for a number of years, with normal, limited success. Air shakers are known to require frequent maintenance, to be noisy and to perform inconsistently. TTD’s current air shaker was known for being extremely inefficient and consuming vast quantities of air. In comparison, the M-50 was a big hit.

“The M-50 electric shaker from MPI has already proven to be more reliable than any other shaker we’ve seen.”

Larry Kubiak, TTD production manager, said, “The M-50 electric shaker from MPI has already proven to be more reliable than any other shaker we’ve seen. We don’t intend to buy air shakers ever again, and will continue to replace them with MPI’s electric shakers, until we have one on every press.”

MPI’s patent-pending electric shakers are not new to the industry. Thousands of units have been sold since their introduction in 2005. As MPI’s electric shakers boast a near zero failure record in the stamping market, a number of similar success stories exist.