Plate magnetic separators are devices designed to remove ferrous contaminants from free-flowing materials, such as grains, powders, and recycled products, ensuring product purity and protecting equipment from damage. These separators utilize a strong permanent magnet to attract and retain iron-containing particles while allowing non-magnetic materials to pass through. They are crucial in various industries, including biomass, cement, pulp and paper, and food processing, where they safeguard processing machinery from tramp iron and enhance the safety and quality of the final products. Plate magnets can be easily installed in chutes, above conveyors, or other material handling systems to effectively extract ferrous debris and improve operational efficiency. By eliminating contaminants, they prevent potential equipment damage and play a vital role in maintaining the integrity of processed materials. All MPI Plate Magnets are Intell-I-Mag® Compatible.

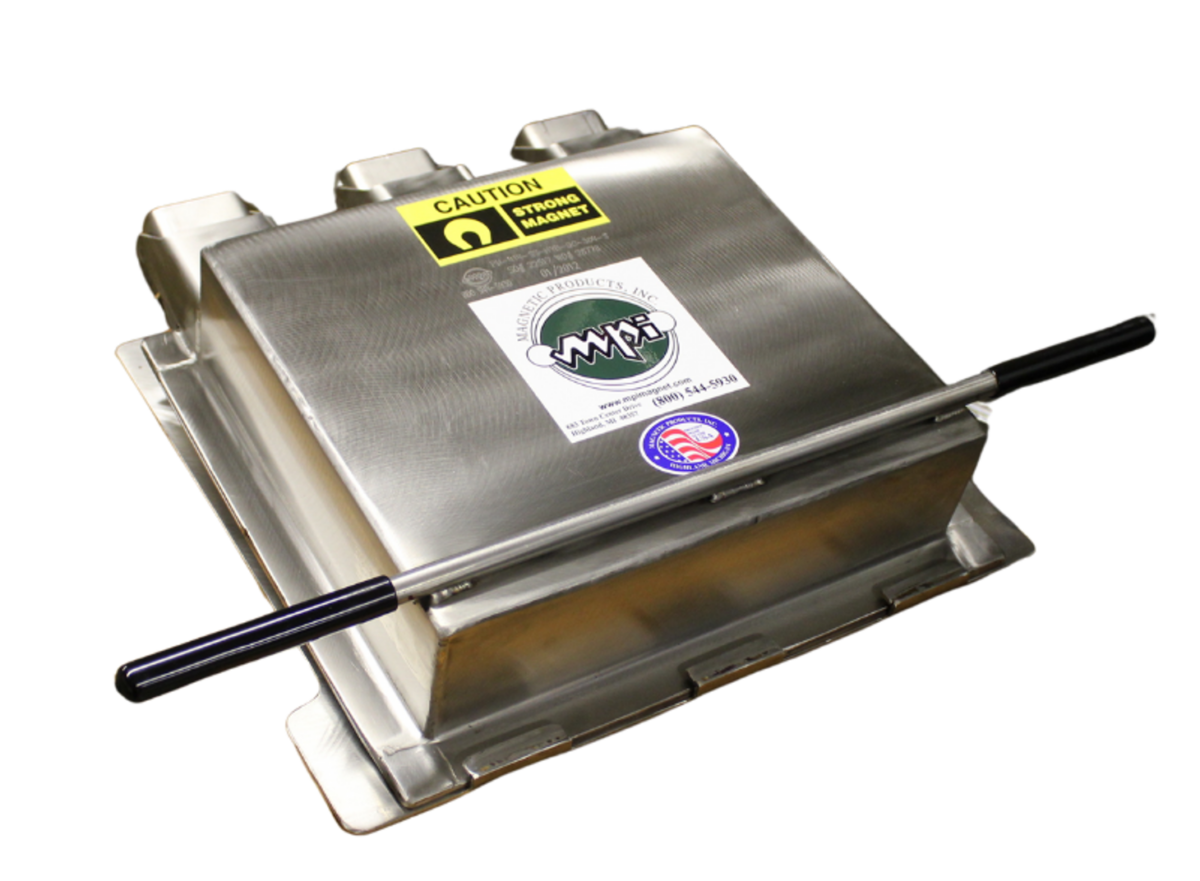

The MPI Manual Clean Plate Magnet offers an economical solution for separating ferrous metals in gravity-fed or conveyor systems. Installed above material flow areas, it effectively captures tramp metal like nails, bolts, and shavings. Operators must manually remove the collected contaminants to ensure ongoing protection for processing equipment. Options include abrasion-resistant and rare earth, ceramic, or hybrid magnet types.

Designed for applications requiring frequent cleaning with minimal downtime, the MPI Quick-Clean Plate Magnet features an easy-to-use cleaning mechanism. The hinged or sliding assembly allows operators to quickly wipe or remove captured ferrous debris without requiring extensive system shutdowns. MPI Quick-Clean Plate Magnets options include abrasion-resistant and rare earth, ceramic, or hybrid magnet types.

The MPI Self-Clean Plate Magnet provides fully automated metal separation for continuous operation in high-volume processing environments. Using a pneumatically controlled cleaning system, the self-cleaning plate magnet automatically removes collected contaminants at timed intervals, ensuring uninterrupted production and minimal maintenance. MPI Self-Clean Plate Magnet options include abrasion-resistant and rare earth, ceramic, or hybrid magnet types.

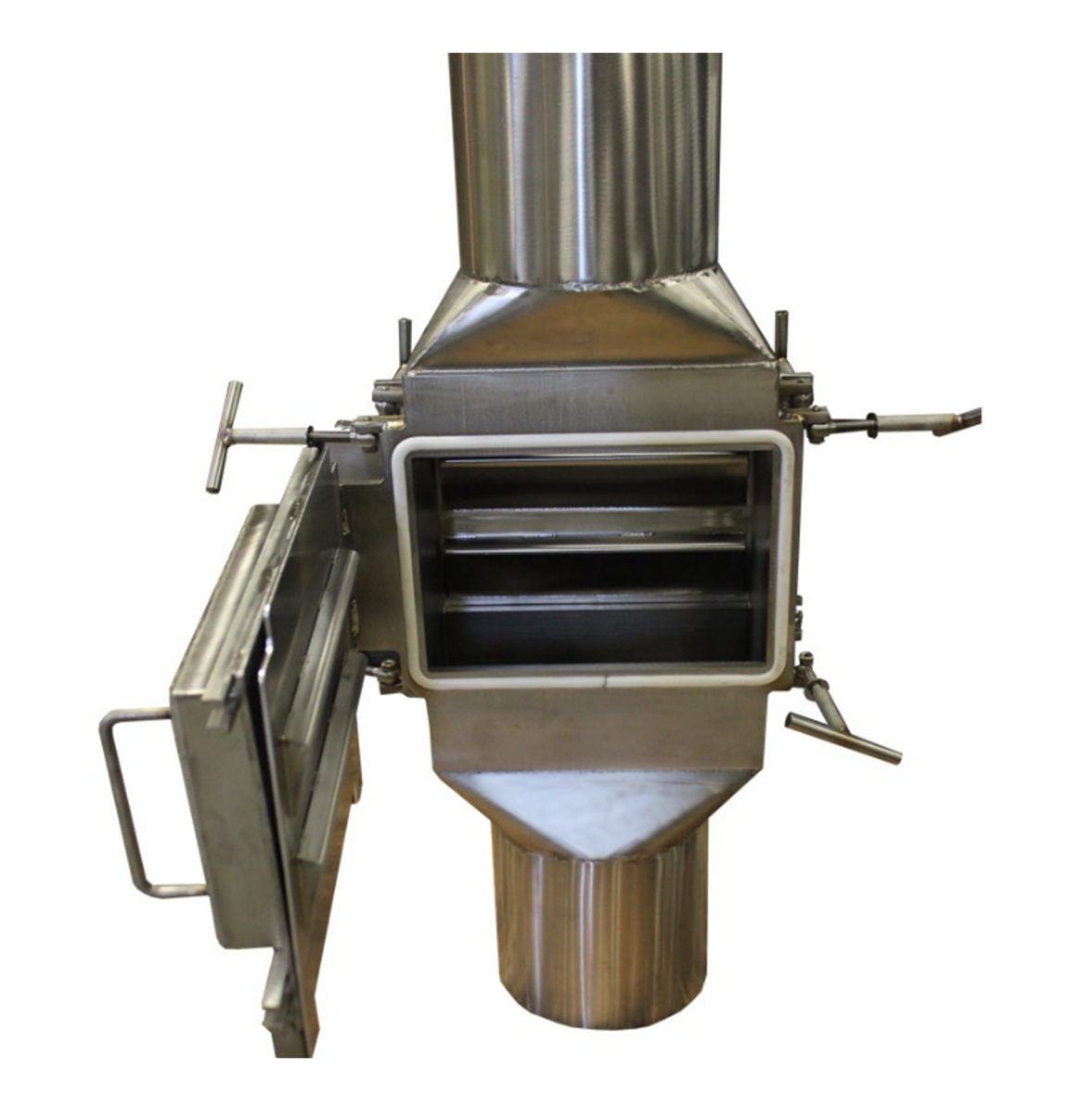

The MPI Manual-Clean Inline Plate is designed for efficient magnetic separation in gravity-fed chutes and pneumatic conveying systems, suitable for low to medium volume product streams. Made from durable stainless-steel, it offers customizable connections and dual plate configurations for easy integration and optimal performance in existing processes. Operators manually access and remove ferrous contaminants via a hinged mount. The separator effectively captures unwanted metal particles in product streams <8 in. deep, ensuring product purity and equipment safety.

MPI’s Quick-Clean Inline Plate Magnetic Separator is designed for effective magnetic separation in gravity-fed chutes and pneumatic systems. It features a quick-clean mechanism for easy removal of ferrous contaminants via a hinged plate magnet. Made from stainless steel with customizable connections, it seamlessly integrates into production lines and effectively captures contaminants in product streams up to eight inches deep. An optional dual magnet configuration is available to improve performance in pneumatic applications.

MPI’s Self-Clean Inline Plate Magnetic Separator automates metal separation, reducing manual cleaning and production downtime. Suitable for gravity-fed chutes and pneumatic systems, it features an automatic cleaning cycle that efficiently removes ferrous contaminants with minimal operator involvement. Its robust stainless-steel housing and customizable connections facilitate easy installation, while dual magnetic poles ensure strong holding capacity for product streams up to 8 in. deep.

The MPI Hump Plate Magnet is designed for use in vertical or sloped gravity-flow chutes to effectively remove tramp metal through two opposing angled plate magnets. This setup slows down material flow, improving metal capture efficiency while reducing wash-off, making it suitable for food, plastics, and chemical processing. Operators must manually remove the collected contaminants to ensure ongoing protection for processing equipment. The magnets come in various options, including Manual, Quick-Clean, Self-Clean, abrasion-resistant, and In-housing models.

MPI’s Suspended Plate Magnets provide efficient metal separation for recycling, mining, and bulk material handling applications. Designed for durability in demanding environments. The quick-clean feature provides hinged access, simplifying maintenance and minimizing downtime. Installed over conveyors, vibratory feeders, or gravity chutes, they provide a reliable, energy-free solution for removing tramp metal. Their focused magnetic circuit enhances separation efficiency, especially at discharge points, making them a cost-effective, high-performance choice for facilities requiring consistent, low-maintenance metal control.

Compatibility Check - Plate Magnet Comparison

Unique Benefits and Considerations

| Plate Magnet Type | Unique Benefits | Considerations |

|---|---|---|

| Manual-Clean Plate Magnet | Intell-I-Mag® Compatible. Cost-effective, no power needed. Low-contamination environments. Affordable, easy-to-install. | Requires manual cleaning; downtime involved. |

| Manual-Clean Plate Magnet In Housing (Inline Plate) | Intell-I-Mag® Compatible. Fully enclosed, dust-tight housing. Protects against external contamination. Cost-effective solution for gravity-fed systems. | Requires manual cleaning; periodic downtime for maintenance. Best for moderate contamination levels. |

| Quick-Clean Plate Magnet | Intell-I-Mag® Compatible. Quick-release cleaning mechanism. Frequent cleaning applications. Faster cleaning, less labor-intensive. | Still requires operator intervention. |

| Quick-Clean Plate Magnet In Housing (Inline Plate) | Intell-I-Mag® Compatible. Enclosed design ensures product purity. Quick-Clean feature minimizes labor time and improves workflow efficiency. Ideal for moderate-to-high contamination levels. | Operators must still manually trigger the cleaning mechanism. Slightly higher cost than manual-clean versions. |

| Self-Clean Plate Magnet | Intell-I-Mag® Compatible. Fully automated cleaning. High-volume, high-contamination applications. Reduces labor costs, maximizes efficiency. | Higher initial cost requires power. |

| Self-Clean Plate Magnet In Housing (Inline Plate) | Intell-I-Mag® Compatible. Enclosed design for dust-free, contaminant-free operation. Fully automated self-cleaning system ensures continuous separation with no manual intervention. Best for high-volume, high-contamination processing. | Higher initial investment; requires power supply. Most efficient option but may require system modifications for integration. |

| Hump Magnet | Available in Manual, Quick, and Self-Clean with Abrasion-Resistant and In-Housing options. Angled design for enhanced separation. Intell-I-Mag® Compatible. Hinged or sliding mechanism. Simple design, no power needed. | Requires some operator intervention periodic maintenance. Newer plate magnet designs and technology are available and offer better separation, more efficiency, and easier integration. |

| Quick-Clean Suspended Plate Magnet | Intell-I-Mag® Compatible. Suspended over conveyors for inline separation. Ideal for conveyor belt systems. No interruption in material flow. | Requires installation above conveyor. |

Industries, Applications and Regulations

For assistance in selecting the most suitable plate magnet for your application or for additional customization options, contact Magnetic Products Inc. today to speak with our team of experts!