Electric Shaker Conveyors

MPI’s patented Electric Shaker is the safest and most efficient way to convey scrap metal, parts, or other bulk materials in a smooth linear motion. The electric shaker motors are attached to a metal pan where the material is conveyed. MPI offers several different variations of the shaker drives designed to convey materials in different application, over varying distances, and transfer rates.

Simple in design, yet extremely rugged and tough, Electric Shakers convey anything from fine metal to the most destructive scrap metal pieces. The patented design allows for silent operation, an efficient electric drive and a modular, scalable system that delivers reduced downtime. These shakers commonly replace belt conveyors, such as steel belt conveyors or rubber belt conveyors, resulting in a quick ROI due to increased uptime and lower changeover costs. Common applications include scrap systems for scrap management or scrap handling and bulk material handling, conveying scrap metal or bulk materials.

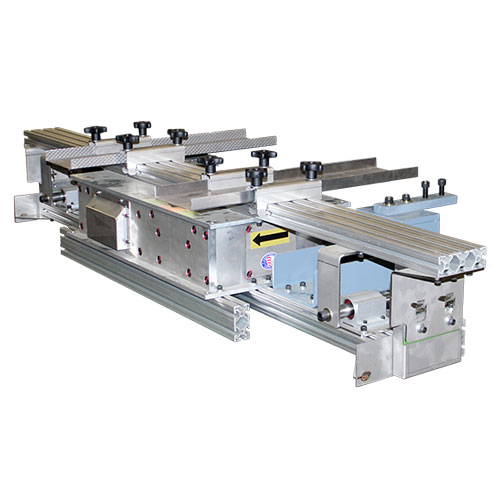

Press Mounted Multi Pan Systems

Press mounted electric shaker conveyors are designed specifically for metal stamping applications where they are mounted to the stamping press using T-slot mounts on the bolster. The systems range in size depending on the width of the required cross bar for the press. In general, the size is matched to the overall width of the press or what is needed for all the different sizes of dies that will be run on the press. The different scrap shaker models are available below based on their maximum crossbar width.

M-10 - 18” Max. Crossbar

For small presses more

M-50 - 36” Max. Crossbar

For medium presses more

M-200 Rack and Pinion System - 168” Max. Crossbar

For large presses more

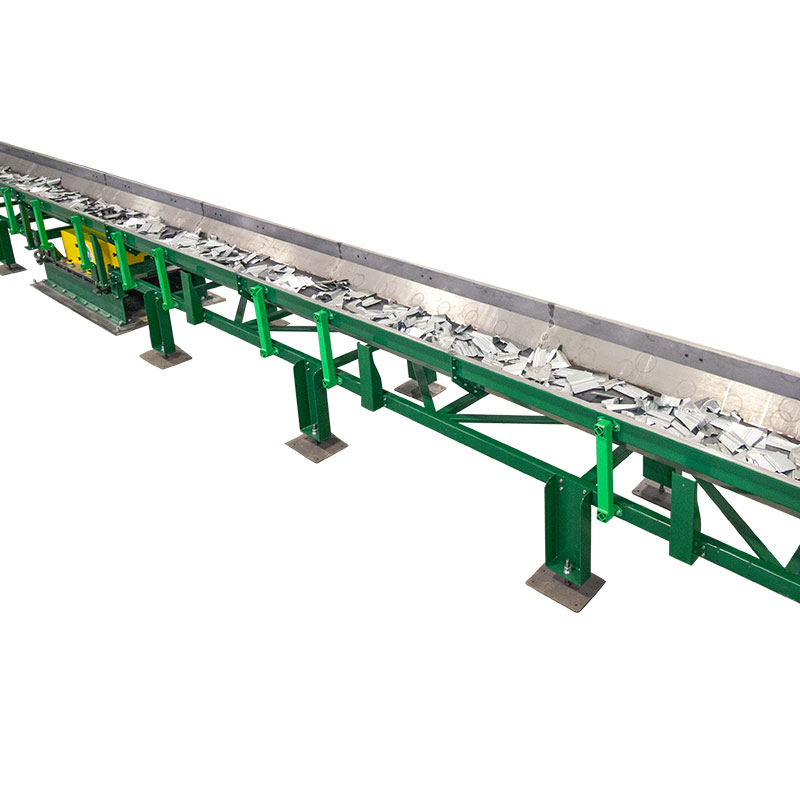

High Capacity Floor Mounted Systems

High-Capacity Floor Mounted Electric Shaker Conveyors are designed to transfer scrap metal, bulk products, or bulk materials reliably over long horizontal distances. The horizontal motion conveyor is designed to transfer at rates of over 10,000 pounds per hour and distances of hundreds of feet. The shaker conveyor features a single formed metal pan that is driven by a single drive at a smooth, low frequency to convey materials in a horizontal motion.