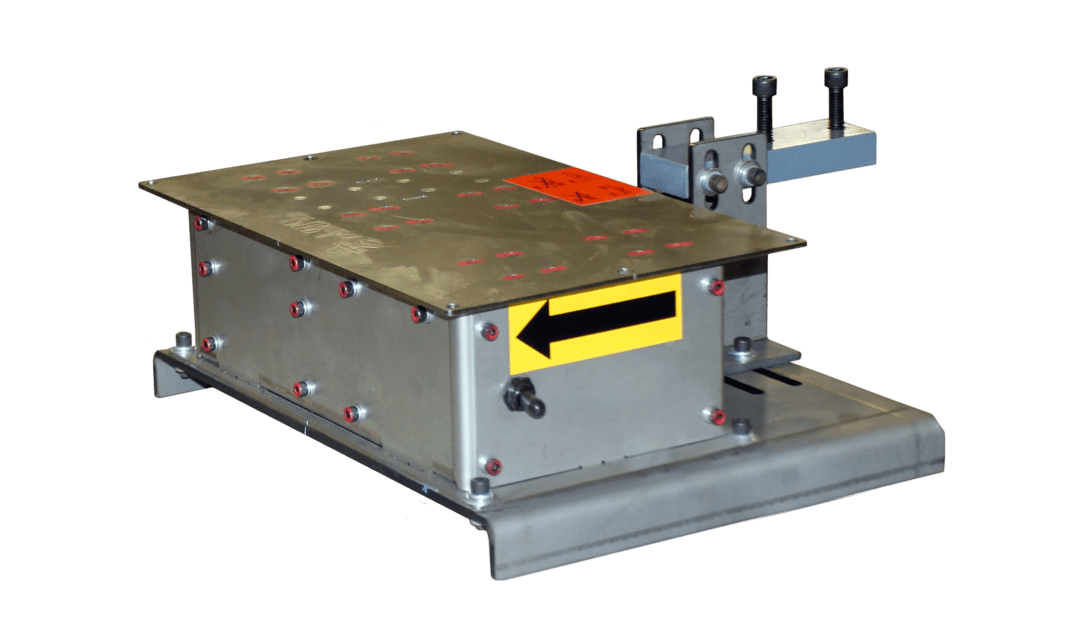

Description

The patented M-10 Electric Shaker Conveyor is designed to remove scrap metal from smaller stamping presses that require up to an 18” crossbar. This scrap removal conveyor makes scrap management simple. The turnkey scrap handling system is designed to start handling scrap right out of the box. Simply mount the unit to the presses T-slots, connect it to 110V power and attach your pans (supplied by MPI or end user), then power on the unit. The system is designed to run without the need for maintenance, air, or lubrication. The scrap conveyor runs at a fixed speed (factory preset at the optimal setting). Items that can be tampered with and may slow production, such as buttons, controls or dials, have been eliminated.

Patent: #US-008,752,695-B2