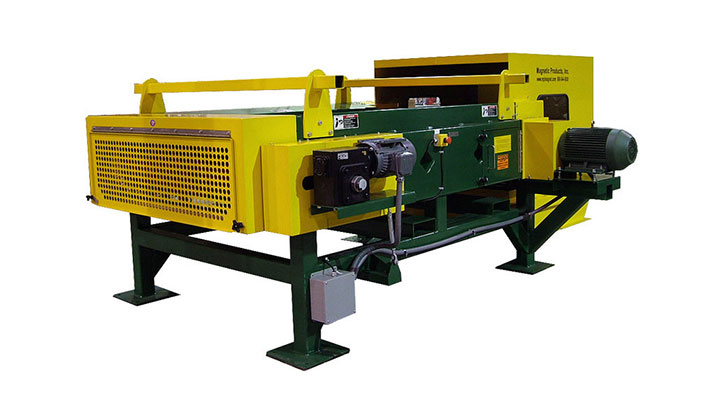

Magnetic Rotary Feeder

|

- Premium Upgraded Magnetic Rotary Feeder:

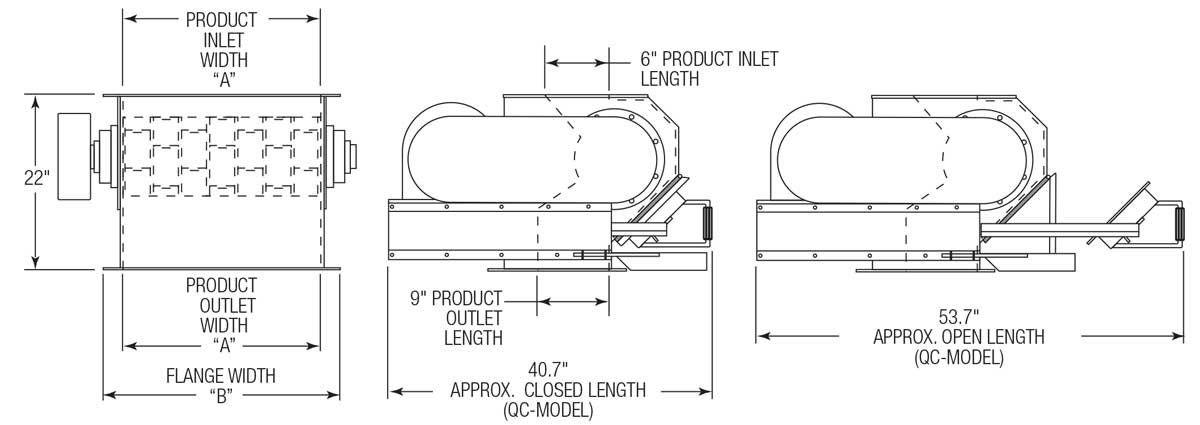

- Direct OEM replacement

- Bolt-on design, built to match the inlet

- Magnet installation is strategically located where the feed of material is most consistently dispersed providing superior magnetic separation before the product enters the mill

- Effortless Magnet Cleaning System:

- Exclusive safe, easy-clean magnetic roller glide system properly protects mill from tramp metal

- The magnet weight rolls on ‘V’ guided roller bearings so that there is virtually no effort needed for magnet cleaning Step 1: Unlatch the plate and pull the handle towards the operator. Stripping mechanism will deposit tramp metal into the collection tray. Step 2: Push handles towards the feeder and re-clamp latches.

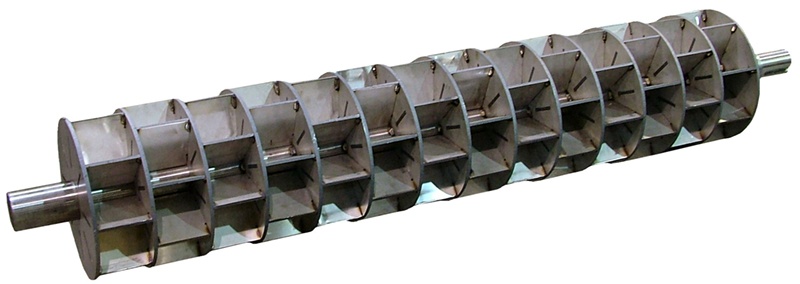

- Stainless Steel Segmented Cup Feeder:

- Delivers even product distribution to mill for increased operation life between replacements

- Fabricated from heavy gauge stainless steel for increased wear resistance

- Powerful 400 Series Ceramic Magnet:

- Optional rare earth or exclusive hybrid magnet options for increased tramp metal protection

- Stepped magnet face maximizes tramp metal removal and minimizes tramp metal “wash-off” between magnet cleanings

- Sani-TIGHT Seal™ Gasket:

- Type: Compression style “O-ring” cord gasket

- Sealing plate: ½” thick machined stainless plate

- 100% Positive seal, cannot be over-compressed

- Sanitary: Gasket can be removed and replaced for wash-down, no adhesive required

- Material: FDA approved silicone

- Adjustable Spring-Loaded Control Gate

- Removable Inspection Cover

- Tramp Metal Collection Tray:

- Attachment: Removable cantilever tray

- Locking notch prevents the tray from vibrating loose

- Self-Clean Model Available:

- Automated cleaning, easy inspection, and maintenance

|

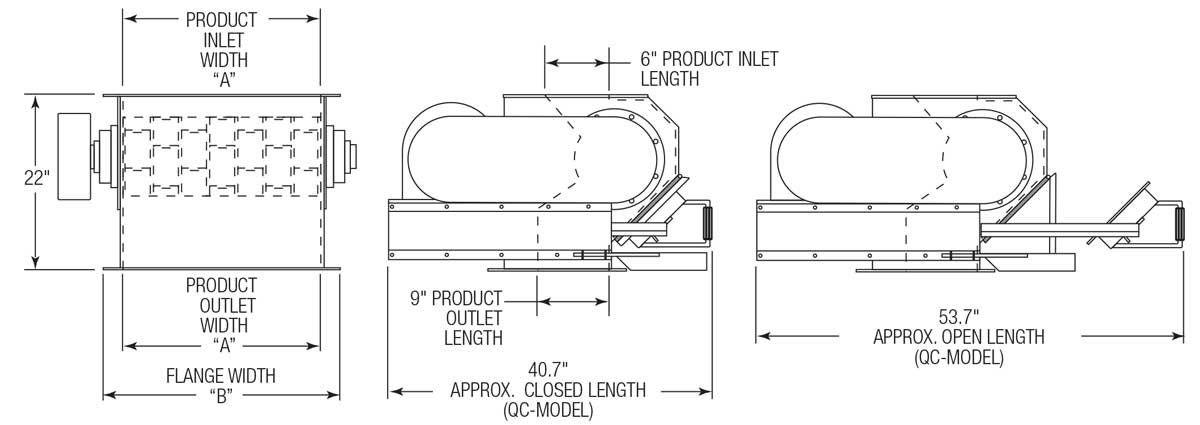

The feed inlet has a spring loaded control gate which allows large metal objects to pass through the feeder without causing damage, where they are captured by the powerful 400 series strength, Ceramic 8 permanent plate magnet. MPI’s exclusive magnet cleaning system is very simple to operate and requires no heavy lifting or handling during cleaning operation.

- US Customary Units

- Metric Units

US Customary Units

| Feeder Size |

Manual Quick-Clean |

Automatic Self-Clean |

Inlet/Outlet Opening Width (A) |

Flange Width (B) |

Motor Horsepower |

| Model # |

Model # |

IN |

IN |

| 3-Row |

MRF-103-QC |

MRF-103-SC |

11.0 |

15.5 |

3/4 |

| 4-Row |

MRF-104-QC |

MRF-104-SC |

14.5 |

19.0 |

3/4 |

| 5-Row |

MRF-105-QC |

MRF-105-SC |

18.0 |

22.5 |

3/4 |

| 6-Row |

MRF-106-QC |

MRF-106-SC |

21.5 |

26.0 |

3/4 |

| 7-Row |

MRF-107-QC |

MRF-107-SC |

25.0 |

29.5 |

1 |

| 8-Row |

MRF-108-QC |

MRF-108-SC |

28.5 |

33.0 |

1 |

| 9-Row |

MRF-109-QC |

MRF-109-SC |

32.0 |

36.5 |

1 |

| 10-Row |

MRF-110-QC |

MRF-110-SC |

35.5 |

40.0 |

1 |

| 11-Row |

MRF-111-QC |

MRF-111-SC |

39.0 |

43.5 |

2 |

| 12-Row |

MRF-112-QC |

MRF-112-SC |

42.5 |

47.0 |

2 |

| 14-Row |

MRF-114-QC |

MRF-114-SC |

49.5 |

54.5 |

2 |

Metric Units

| Feeder Size |

Manual Quick-Clean |

Automatic Self-Clean |

Inlet/Outlet Opening Width (A) |

Flange Width (B) |

Motor Horsepower |

| Model # |

Model # |

MM |

MM |

| 3-Row |

MRF-103-QC |

MRF-103-SC |

249.4 |

393.7 |

3/4 |

| 4-Row |

MRF-104-QC |

MRF-104-SC |

368.3 |

482.6 |

3/4 |

| 5-Row |

MRF-105-QC |

MRF-105-SC |

457.2 |

571.2 |

3/4 |

| 6-Row |

MRF-106-QC |

MRF-106-SC |

546.1 |

660.4 |

3/4 |

| 7-Row |

MRF-107-QC |

MRF-107-SC |

635.0 |

749.3 |

1 |

| 8-Row |

MRF-108-QC |

MRF-108-SC |

723.9 |

838.2 |

1 |

| 9-Row |

MRF-109-QC |

MRF-109-SC |

812.8 |

927.1 |

1 |

| 10-Row |

MRF-110-QC |

MRF-110-SC |

901.7 |

1016.0 |

1 |

| 11-Row |

MRF-111-QC |

MRF-111-SC |

990.6 |

1104.9 |

2 |

| 12-Row |

MRF-112-QC |

MRF-112-SC |

1079.5 |

1193.8 |

2 |

| 14-Row |

MRF-114-QC |

MRF-114-SC |

1257.3 |

1371.6 |

2 |

- Magnet Cleaning Method:

- Quick-clean roller guide system (standard)

- Self-clean pneumatic system with safety cage

- Magnet :

- 400 Series Ceramic (standard)

- Rare earth 200 series

- Hi-G hybrid rare earth 400 series

- Drive Package:

- US Manufactured TEFC (standard)

- Input: 230-480V / 3P / 60Hz

- US Manufactured TEXP (Explosion Proof)

- Inverter duty drive

- Miscellaneous:

- Limit switches for closed confirmation

- MPI standard Honeywell complete with mounting bracket

- Custom switch brand and mounting locations available

- Zero speed switches

- Lifting lugs

- Custom flange bolt hole pattern

- Companion flanges

- Matching flanges for matching bolt pattern in inlet and outlet

- Customer to weld onto existing equipment