- Intuitive Design

- Multiple languages available

- Four-level password: operator, manager, technician and service

- Easy-to-follow, step-by-step, high-graphic screens help users set standards for product testing

- Simple operation means no expensive service calls to adjust settings

- Four Quadrant Technology

- 360° analysis of the product signature

- Metal threshold follows the signature so metal detection occurs in the whole product

- The detector adjusts settings to detect metals in the most “difficult” products such as cheese or high salt content foods

- Zero Maintenance Electronics

- All-solid-state electronics housed on one mainboard – ensures years of reliable performance offering the lowest cost of ownership on the market

- Digital Balance Control adjusts for temperature and humidity fluctuations by monitoring coil balance more than 200 times per second

- 2-year standard warranty

- Documentation and Traceability

- Metal detectors are considered a critical control point, and continuous checking is required to meet standards. Cassel metal detectors can be programmed to automatically remind the operator to test equipment performance at pre-set intervals. A list of metal contaminant detections, changes in parameter settings, etc., is stored with both date and time. This list can be viewed on-screen or the data can be downloaded to a Windows-based PC.

- Performance validation system (PVS) automatically prompts the operator to test Metal Detector performance at pre-set intervals

- Operational history: events are recorded with the date and time and can be viewed on the control panel or export the log via a serial port

- Data will not be lost during a power outage

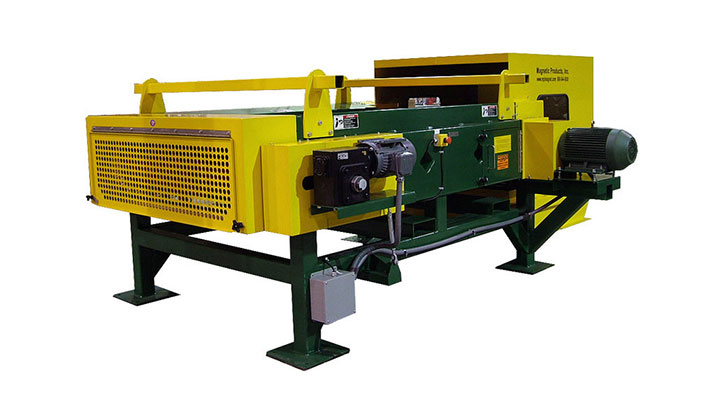

The conveyor belt carries an object through this field and when an abnormality occurs, the magnetic field changes and the detector is signaled.

- Designed for detection performance of 1.5 mm ferrous, 2.0 mm non-ferrous and 2.0 mm stainless steel in large bags, typically 50-100 lbs.

- Hygienic food industry design available to ensure compliance with good manufacturing principles

- Harsh environment rating as standard on sensor head to maintain stability regardless of the environment

- Typical options include wash down up to IP69k, reject devices, proximity sensors, alarms and special belting

- Compatible with the METAL SHARK 2A to provide high quality inspection

- SHARKNET® software

- Monitor real-time inspection results and actively manage product inspection equipment from a central computer

- Enables automatic downloading of data documentation to a Windows-based PC

- Support required compliance with: HACCP-SQF 2000-BRC-GMP-IFS5-FSSC 22000/PAS 220

- Remote maintenance capability by operators and Cassel technicians

- All data is stored in an SQL database for easy export or integration if needed