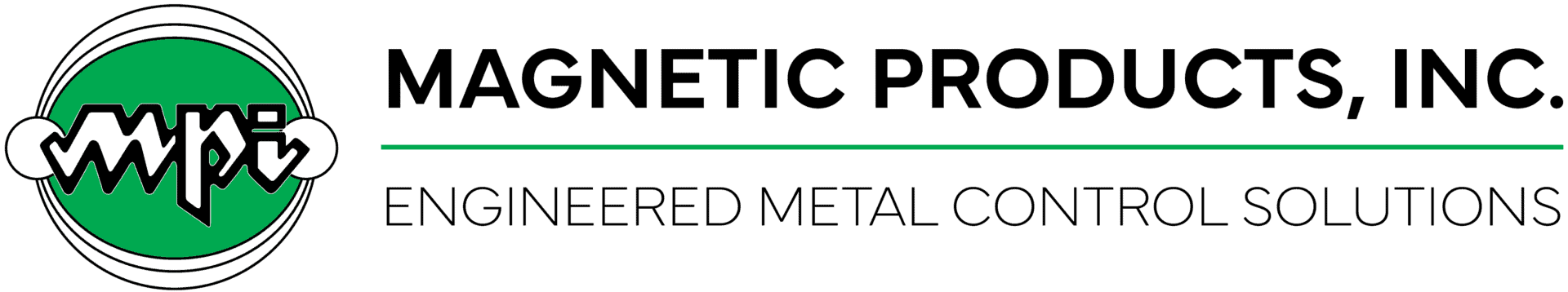

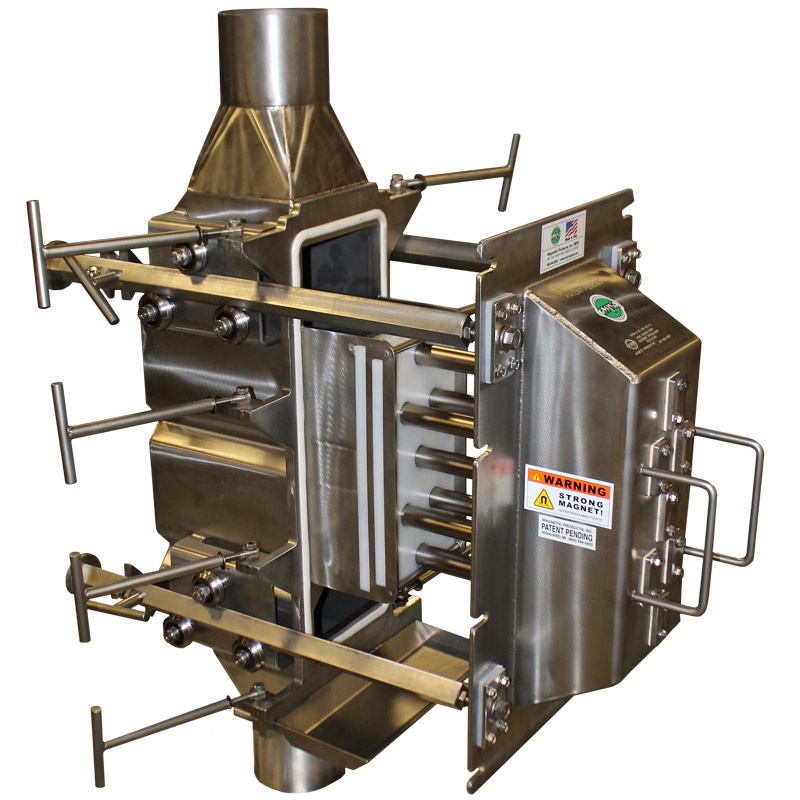

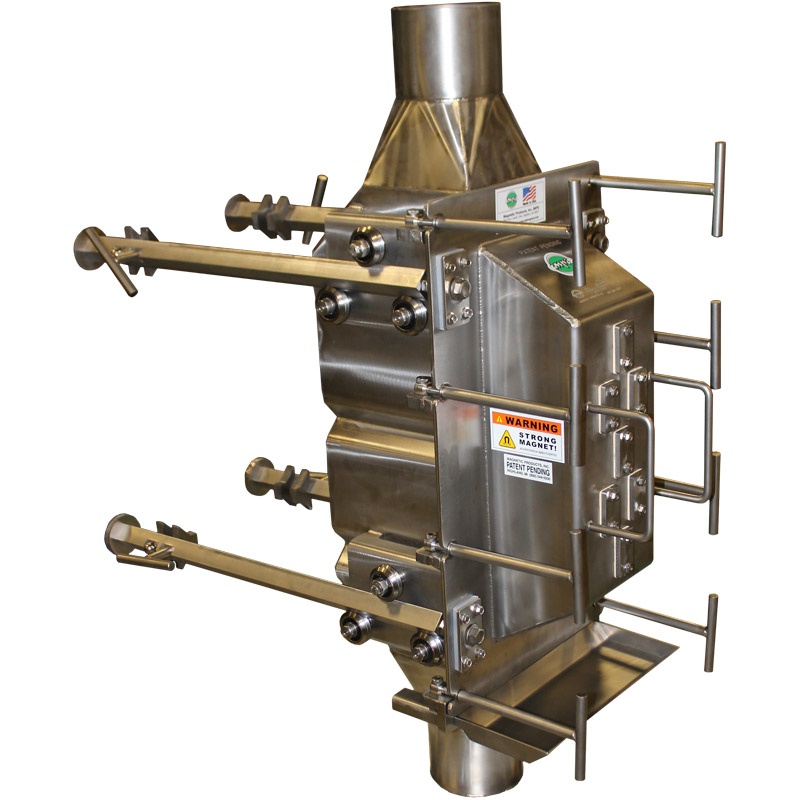

Description

MPI’s new patent-pending pneumatic drawer style magnetic separator is ideally suited to capture small contaminants, such as wire, metal shavings and metal wear from dry powder or granular free-flowing product streams in pneumatically conveyed lines up to 15 PSI. Used in primary, secondary or finishing applications, this next generation drawer magnet delivers the highest levels of equipment protection and product purity.