|

- Flowability and Strength Variations

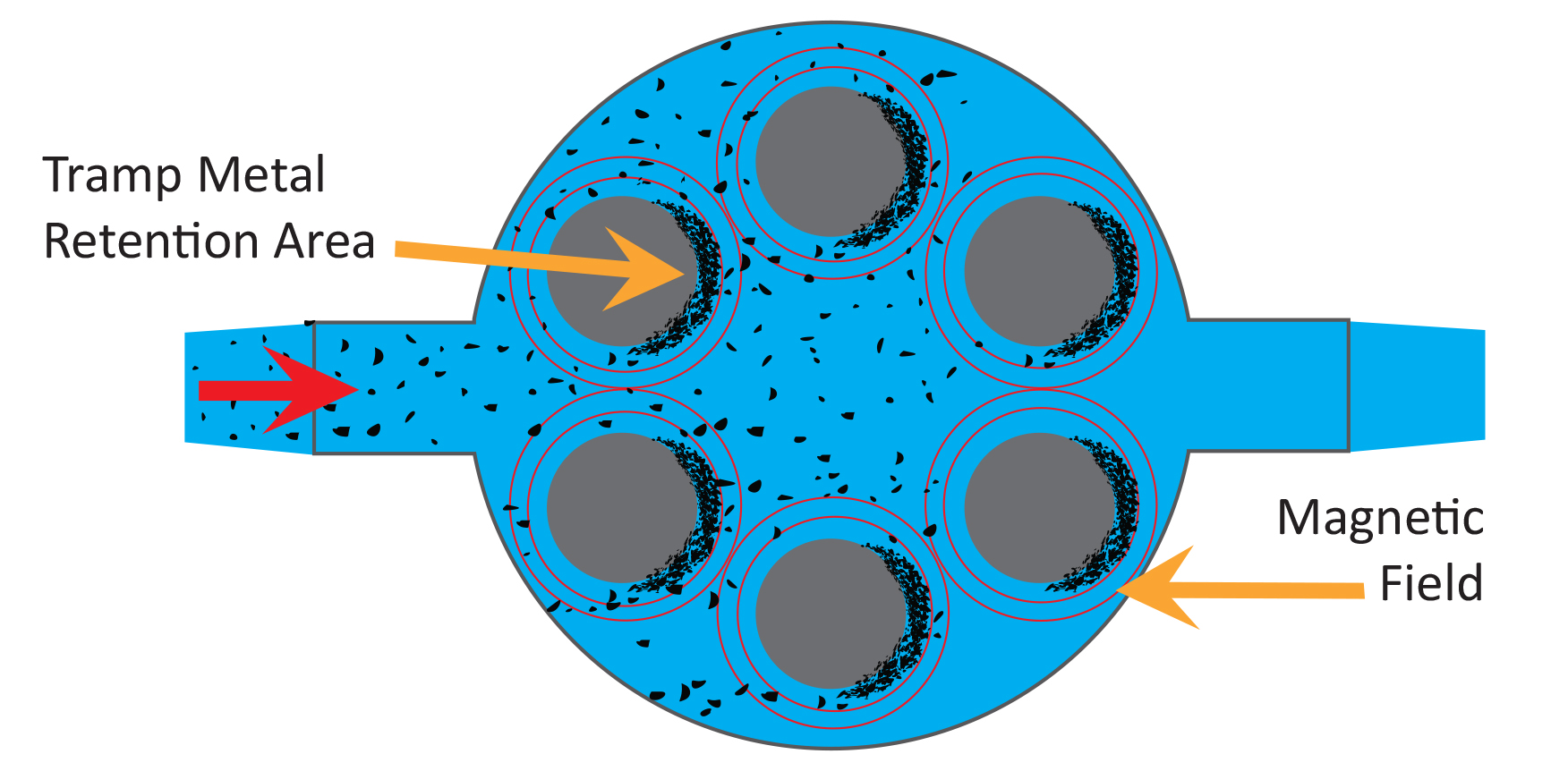

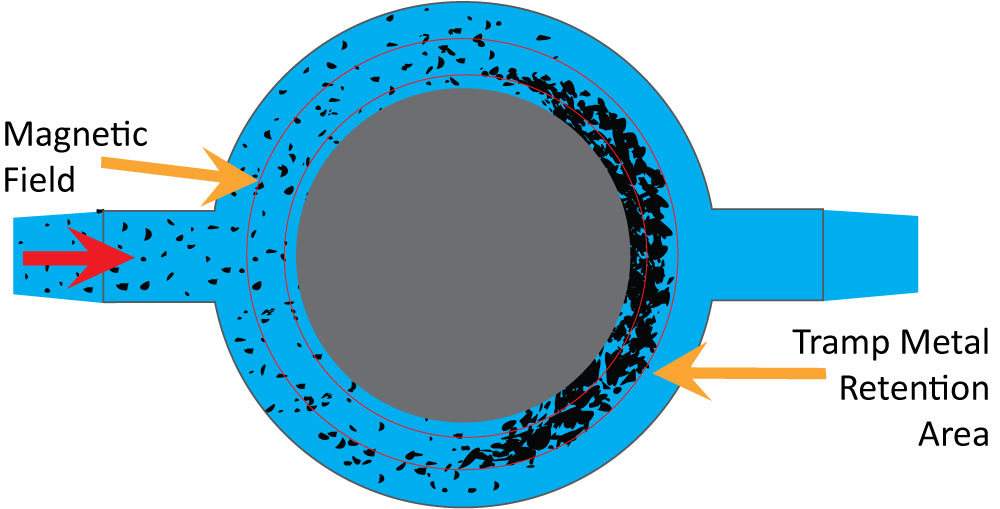

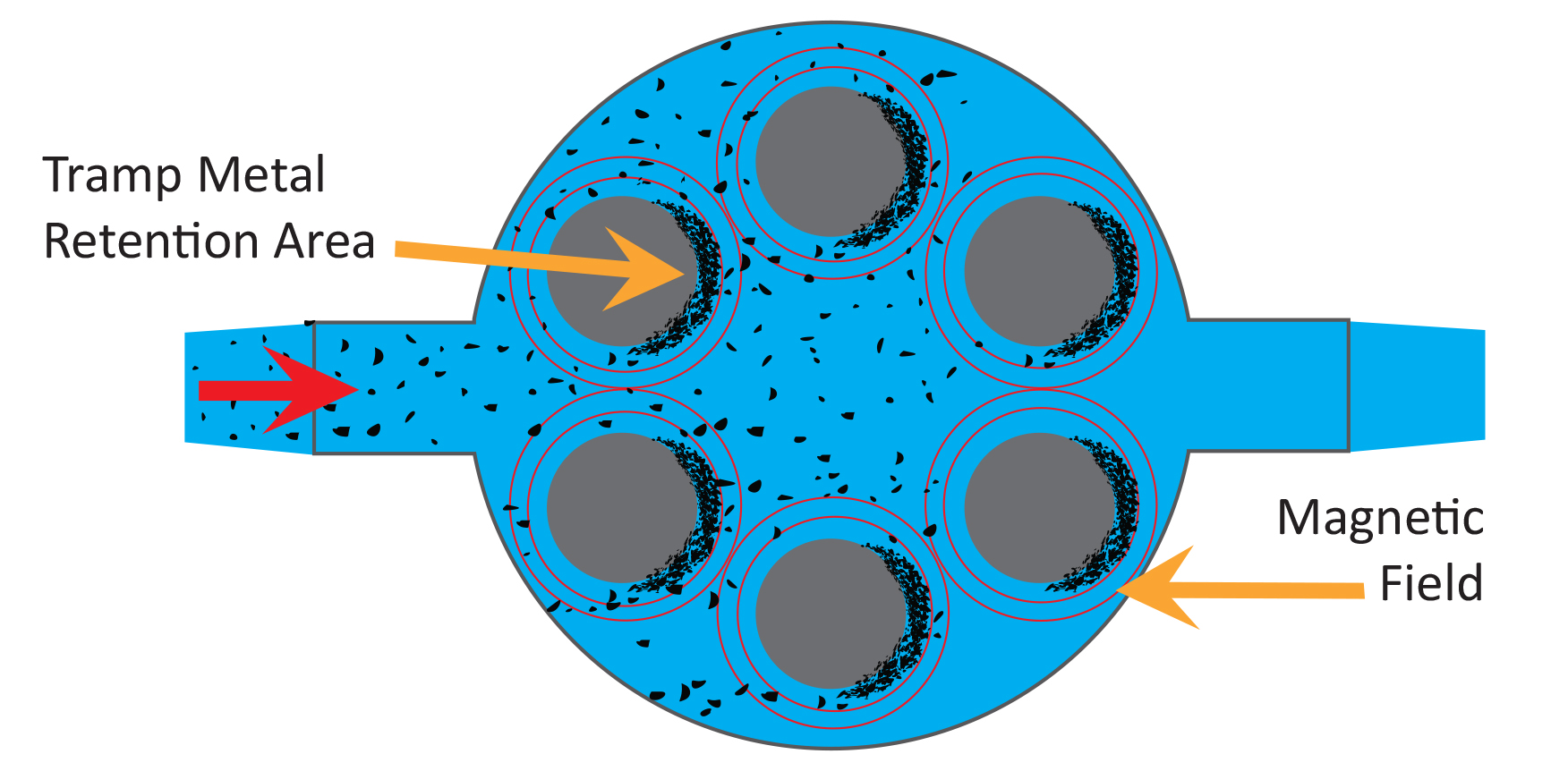

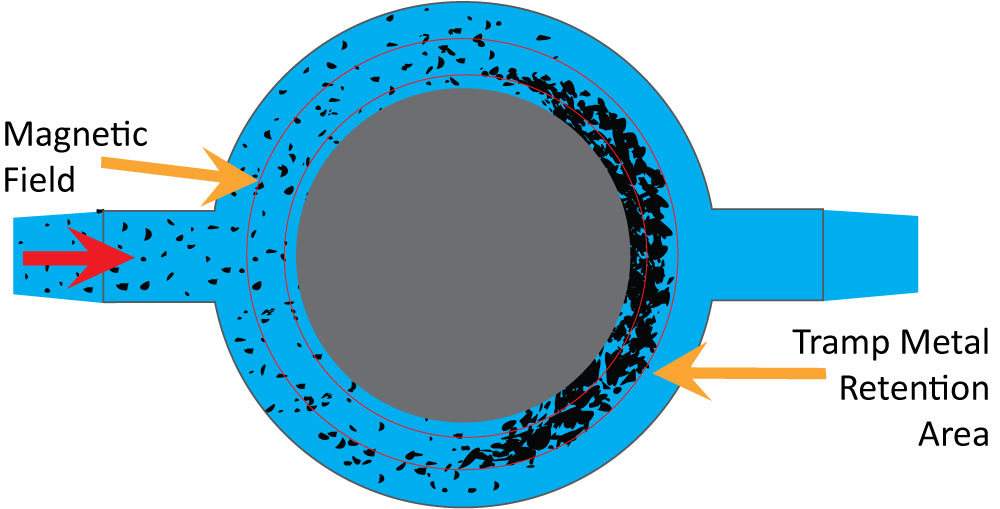

- Product is pumped through the magnet where ferrous tramp metal collects on either an array of 1” diameter magnetic tubes or a single 3” diameter magnetic tube. The tramp metal collects behind the tubes in the direction of product flow to prevent tramp metal wash off. Non-magnetic particles are separated by gravity and collect in the sump located in the bottom of the magnet enclosure.

- Diameter Ranges

- Standard inlet / outlet sizes available from 1.5” diameter up to 12” diameter (HP model required for sizes over 4” diameter)

- Adaptable to Existing Lines

- Easy installation into existing line using sanitary tri-clover, threaded or ANSI 150 pound inlet and outlet flanges

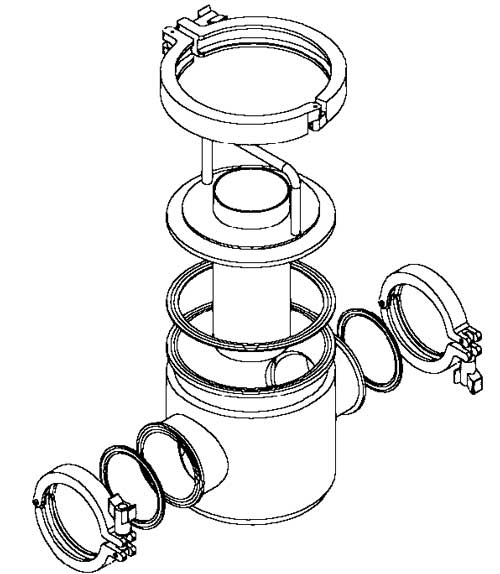

- Tube Configuration for Easy Cleaning

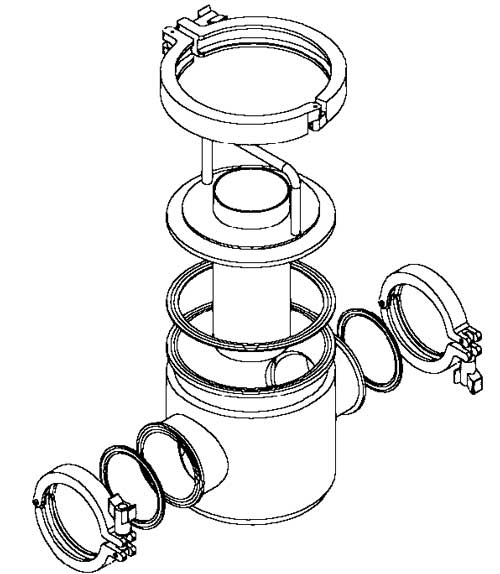

- Exclusive tube configuration for easy removal of ferrous tramp metal from magnetic tubes

- Beauty Rings Protect Tubes from Impact

- Welded tube support located on the bottom of the magnet element

- Ensures proper magnetic protection by eliminating bending of the tubes inwards due to product flow or handling during cleaning

- Increases magnet life by preventing broken welds on end of tubes caused by impact during cleaning

- Detectable Gasket Material

- Metal detectable magnet housing gasket standard (Buna material)

- Maximum Pressure Levels

- Designed for operating at up to 150 PSI maximum pressure (at 248°F) depending on model size

- High-Temperature Rating

- Designed for operating temperatures up to 356°F depending on model configurations

- USDA Certified

- USDA approved certified sanitary (USDA AMS NSF / ANSI / 3-A14159-1 2002) available

|

The tramp metal collects at the downstream side of the magnetic tubes, preventing tramp metal “wash-off” during the continuous product flow around and through the magnetic field without restricting the product flow. Additionally, non-magnetic particles are trapped, by gravity, in a sump beneath the magnetic element.

| 1″ Tube |

3″ Tube |

|

|

| 1″ Tube Design |

3″ Tube Design |

|

|

- US Customary Units

- Metric Units

US Customary Units

| SIZE |

Fluid and Strained Product |

Fibrous and Crushed Product |

Viscous and Heavy Product |

| IN |

GALLONS/MINUTE |

GALLONS/MINUTE |

GALLONS/MINUTE |

| 2 |

1-64 |

1-53 |

1.0-3.3 |

| 3 |

65-132 |

54-116 |

34-77 |

| 4 |

133-154 |

117-132 |

78-105 |

| 6 |

365-714 |

220-429 |

145-284 |

LFT Series Selection Guide

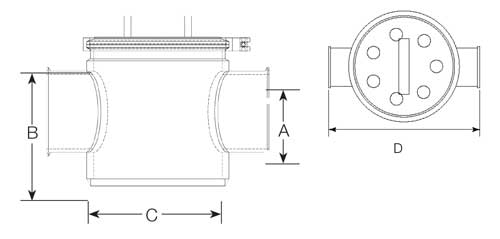

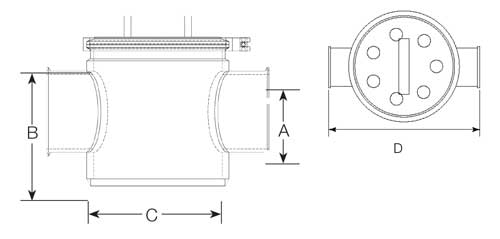

| Model # |

Pipe Diameter (A) |

Unit Height (B) |

Unit Diameter (C) |

Total Width (D) |

Unit Weight |

# of

Magnetic Tubes |

| IN |

IN |

IN |

IN |

LBS |

| LFT-2 |

2 |

7 |

6.5 |

9 |

26 |

5 |

| LFT-3 |

3 |

7 |

6.5 |

9 |

37 |

5 |

| LFT-4 |

4 |

8 |

8.5 |

11 |

50 |

6 |

| LFT-6 |

6 |

10.5 |

10.75 |

16.5 |

125 |

7 |

Metric Units

| SIZE |

Fluid and Strained Product |

Fibrous and Crushed Product |

Viscous and Heavy Product |

| MM |

LITERS/SECOND |

LITERS/SECOND |

LITERS/SECOND |

| 51 |

.06-4.0 |

.06-3.3 |

.06-2.1 |

| 76 |

4.1-8.3 |

3.4-7.3 |

2.1-4.9 |

| 102 |

8.4-9.7 |

4.7-8.3 |

4.9-6.6 |

| 125 |

23-45 |

14-27 |

9-18 |

LFT Series Selection Guide

| Model # |

Pipe Diameter (A) |

Unit Height (B) |

Unit Diameter (C) |

Total Width (D) |

Unit Weight |

# of

Magnetic Tubes |

| MM |

MM |

MM |

MM |

KGS |

| LFT-2 |

51 |

178 |

165 |

229 |

12 |

5 |

| LFT-3 |

76 |

178 |

165 |

229 |

17 |

5 |

| LFT-4 |

102 |

203 |

216 |

279 |

32 |

6 |

| LFT-6 |

152 |

267 |

273 |

419 |

57 |

7 |

- Pipe Size: Available in diameters from 1” to 6” in any increment.

- Maximum Operating Pressure:

- 150 PSI at 248°F (120°C) (standard on sizes 4” and smaller)

- 75 PSI at 248°F (120°C) (standard on sizes 5” and larger)

- Cleaning Method:

- Manual clean (standard)

- Manual quick-clean with a sleeve over stripper for easy removal of tramp metal. Not recommended for sticky products. Sleeve over design reduces magnetic performance at contact.

- Magnet Element: Four different styles are available depending on your application

- Array of 1” diameter tubes designed for liquids, purees, and products with solids 1/2” and smaller

- Single 3” diameter tube mounted in the center of housing designed for products with fragments, solids or chunks up to 1” in size

- Plate magnet design with one or two plate magnets mounted on the outside of the product flow for very difficult flowing and fibrous products

- Combination magnet and screen design

- Material Construction:

- 304 Stainless Steel (standard)

- 316 Stainless Steel

- Magnetic Tubes:

- REN Rare Earth (standard)

- Hi-G high-performance Rare Earth

- TW Thin Wall high-performance Rare Earth

- Magnetic Material Temperature:

- 176°F (80°C) @ 52+ MGOe (rare earth) (standard)

- 248°F (120°C) @ 48 MGO (rare earth)

- 356°F (180°C) @ 38 MGO (rare earth)

- 662°F (350°C) @ 30 MGO (rare earth)

- Tube Coatings:

- Stainless steel with no coating (standard)

- Synergistic Coating [reference datasheet Synergistic Coating]

- Gasket Material:

- Buna material, color red, metal detectable, temperature range: -40°F (-40°C) to 225°F (107°C) (standard)

- Viton material, color white, temperature range: -10°F (-23°C) to 400°F (204°C)

- Customer specified

- Inlet Flange Design:

- Tri-Clover sanitary heavy-duty quick-release clamp (standard)

- NPT threads (for use of spin on flanges)

- ANSI 150 pound flange

- Plain end for welded pipe installation

- Customer specified

- Outlet Flange Design:

- Tri-Clover sanitary heavy-duty quick-release clamp (standard)

- NPT threads (for use of spin on flanges)

- ANSI 150 pound flange

- Plain end for welded pipe installation

- Customer specified

- Water Jacket: For heating or cooling products

- Not included (standard)

- Included

- Drain: Ball valve located on the bottom of the unit to drain before opening the magnet

- Not included (standard)

- Included

- Lock Out Tab: Prevents unauthorized entry via customer supplied and an installed padlock

- Not included (standard)

- Included

- USDA Magnet Certification: