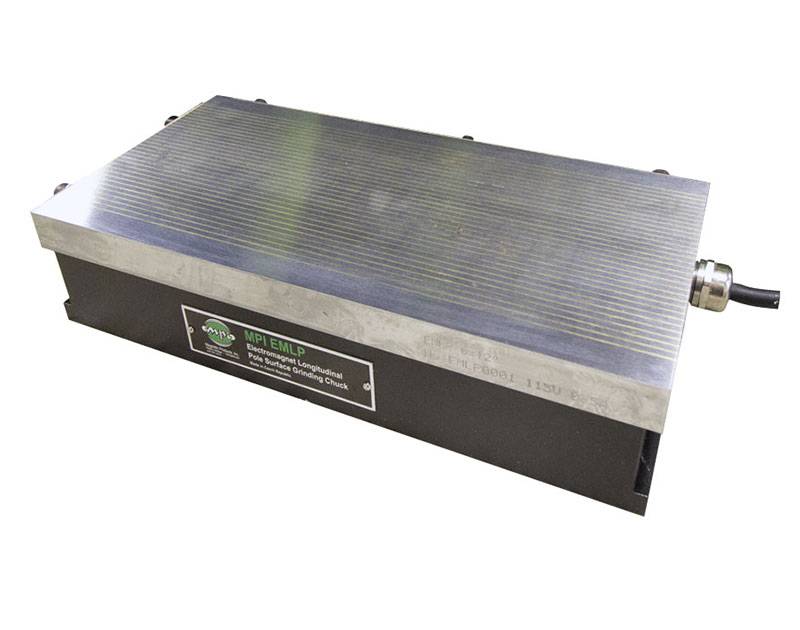

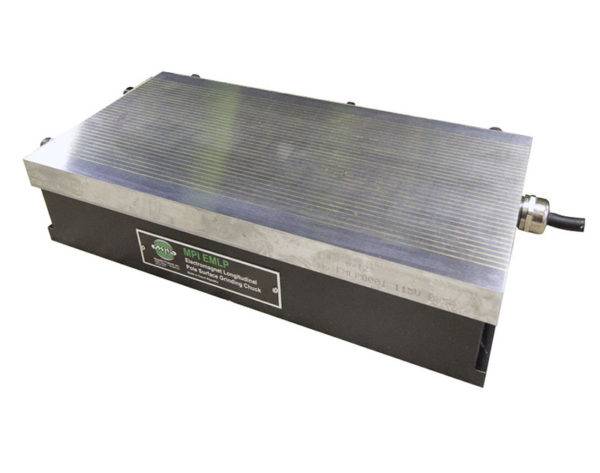

Electromagnet Longitudinal Pole Surface Grinding Chuck

- Design with firmly embedded coils

- Waterproof design

- Electromagnet is easily operated by pressing the button on the control unit which also ensures variable adjustment of the force to create the optimum conditions for clamping

- Suitable for sinker EDM applications

- Magnetic field does not affect EDM operation

- Powerful holding over entire chuck surface

- Fine pole divisions – for more uniform magnetic holding of small parts

- Low height for added clearance on larger workpieces

- One (1) year warranty for the magnetic system

- Manufactured in Europe to the highest quality standards

- Included with Each Magnet: Supplied with two (2) hold down clamps

- Note: Control Unit sold separately

Electromagnet Longitudinal Pole Surface Grinding Chucks consist of long, narrow steel strips running lengthwise. These are called “poles”. Workpiece(s) must cross these poles to contact North and South poles and close the magnetic circuit. This ensures a proper magnetization of your workpiece(s) and thus a good holding force. It is not always obvious to identify North and South poles, therefore it is recommended to cross as many steel strips as reasonably possible.

Narrow workpieces placed parallel to the poles and touching only one pole will not be clamped adequately. If the shape and/or size of your workpiece(s) does not allow for a proper contact you may have to use auxiliary laminated blocks. The bigger the contact area, the higher the holding force. Also, the thicker the workpiece, the more magnetic flux it can absorb the more holding force will be generated. Magnetic force lines flow from North to South poles through the workpiece. They do not like to flow through air or nonmagnetic materials.

Poor surface conditions like a rough surface, rusty surface or uneven surface will create an airgap thus reducing the holding force. Flat, smooth, and clean workpieces will achieve the highest holding force. Therefore, deburr workpieces and file chock marks if necessary. Always keep the chuck’s clamping surface clean and redress if the surface is scratched badly or damaged.

The Electromagnetic Longitudinal Fine Pole Surface Grinding Chuck is used for efficient clamping of very small workpieces during precise surface grinding. It is an electromagnetic chuck which provides holding force over the entire surface of the top plate. With minimum warming of the working area, you will obtain a unique workpiece clamp for precise grinding.

Efficient production is supported by easy operation using the control unit – just press the button or turn the switch to regulate the holding force for ideal conditions in industrial operation. This unit also allows automatic demagnetization so that no residual magnetism remains in the workpiece after unclamping.

When to choose the Electromagnet Longitudinal Fine Pole Surface Grinding Chuck:

The MPI Electromagnet Longitudinal Fine Pole Surface Grinding Chuck is used for efficient clamping of very small workpieces during precise surface grinding.

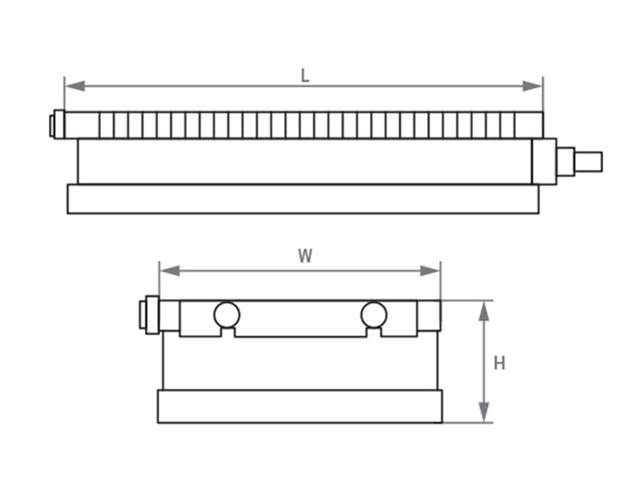

Important parameters:

Use:

|

|

US Customary Units

| Part Number | Description | Recommended Control |

W | L | H | Weight | AMPS |

OHMS |

Volt Input |

Watts |

|

| IN | IN | IN | LBS | ||||||||

| EMLP-150300-SGC | 6″ x 12″ Electromagnet Longitudinal Fine Pole | EMCU-150W | 6 | 12 | 2.8 | 46 | 0.49 | 233 | 110 | 57 | |

| EMLP-150450-SGC | 6″ x 18″ Electromagnet Longitudinal Fine Pole | EMCU-150W | 6 | 18 | 2.8 | 70 | 0.77 | 149 | 110 | 89 | |

| EMLP-200450-SGC | 8″ x 18″ Electromagnet Longitudinal Fine Pole | EMCU-150W | 8 | 18 | 2.8 | 100 | 0.98 | 117 | 110 | 113 | |

| EMLP-200600-SGC | 8″ x 24″ Electromagnet Longitudinal Fine Pole | EMCU-150W | 8 | 24 | 2.8 | 130 | 1.06 | 110 | 110 | 122 | |

| EMLP-250500-SGC | 10″ x 20″ Electromagnet Longitudinal Fine Pole | EMCU-150W | 10 | 20 | 2.8 | 180 | 1.49 | 77 | 110 | 172 | |

| EMLP-250600-SGC | 10″ x 24″ Electromagnet Longitudinal Fine Pole | EMCU-150W | 10 | 24 | 3 | 215 | 1.3 | 88 | 110 | 150 | |

| EMLP-300600-SGC | 12″ x 24″ Electromagnet Longitudinal Fine Pole | EMCU-150W | 12 | 24 | 3 | 185 | 1.24 | 92 | 110 | 143 |

Metric Units

| Part Number | Description | Recommended Control |

W | L | H | Weight | AMPS |

OHMS |

Volt Input |

Watts |

|

| MM | MM | MM | KG | ||||||||

| EMLP-150300-SGC | 152 x 305 Electromagnet Longitudinal Fine Pole | EMCU-150W | 152 | 305 | 71 | 21 | 0.49 | 233 | 110 | 57 | |

| EMLP-150450-SGC | 152 x 457 Electromagnet Longitudinal Fine Pole | EMCU-150W | 152 | 457 | 71 | 32 | 0.77 | 149 | 110 | 89 | |

| EMLP-200450-SGC | 203 x 457 Electromagnet Longitudinal Fine Pole | EMCU-150W | 203 | 457 | 71 | 45 | 0.98 | 117 | 110 | 113 | |

| EMLP-200600-SGC | 203 x 610 Electromagnet Longitudinal Fine Pole | EMCU-150W | 203 | 610 | 71 | 59 | 1.06 | 110 | 110 | 122 | |

| EMLP-250500-SGC | 254 x 508 Electromagnet Longitudinal Fine Pole | EMCU-150W | 254 | 508 | 71 | 82 | 1.49 | 77 | 110 | 172 | |

| EMLP-250600-SGC | 254 x 610 Electromagnet Longitudinal Fine Pole | EMCU-150W | 254 | 610 | 76 | 98 | 1.3 | 88 | 110 | 150 | |

| EMLP-300600-SGC | 305 x 610 Electromagnet Longitudinal Fine Pole | EMCU-150W | 3052.8 | 610 | 76 | 84 | 1.24 | 92 | 110 | 143 |

Currently no options available for this product.