How Electromagnets Can Keep You Out of Trouble

Electromagnets are simple.

Electromagnets consist of a length of conductive wire wrapped around a piece of metal. Introduce an electric current from a battery or other source and the electromagnet comes to life. A magnetic field around the coiled wire magnetizes the metal as if it were a permanent magnet.

The ability to turn the magnetic field on or off is what makes the electromagnet so useful. This is what separates them from permanent magnets like the ones holding your children’s artwork on your refrigerator.

Permanent magnets have two poles — north and south. They attract steel and iron. Like poles attract and opposite poles repel.

An electromagnet will behave in the same manner. But, the magnetic field is temporary — it only exists when an electric current is flowing. This on-demand magnetism is what makes the electromagnet so useful.

The strength of the magnetic field generated is proportional to the amount of current going through the wire. This permits control of the magnetic field and makes them useful for multiple applications.

Electromagnets are components of other electrical devices. You will find them in motors, generators, electromechanical solenoids, relays, loudspeakers, MRI machines, scientific instruments, and magnetic separation equipment.

Danish scientist Hans Christian Ørsted discovered in 1820 that electric currents create magnetic fields. British scientist William Sturgeon invented the electromagnet in 1824.

Sturgeon’s first electromagnet was a horseshoe-shaped piece of iron that was wrapped with about 18 turns of bare copper wire. When the current passed through the coil, it magnetized the iron. Stop the current, and it lost its magnetization. But, Sturgeon’s magnets were weak. An insulated wire had not yet been invented so he could only wrap a single, spaced out layer of wire around the core. This limited the number of turns.

In 1830, American scientist Joseph Henry improved and popularized the electromagnet. He used wire insulated by silk thread. This allowed him to wind many layers of wire on cores. With thousands of turns of wire, he created powerful magnets.

The first major use for electromagnets was in telegraph sounders.

There are two types of electromagnets — portative and tractive.

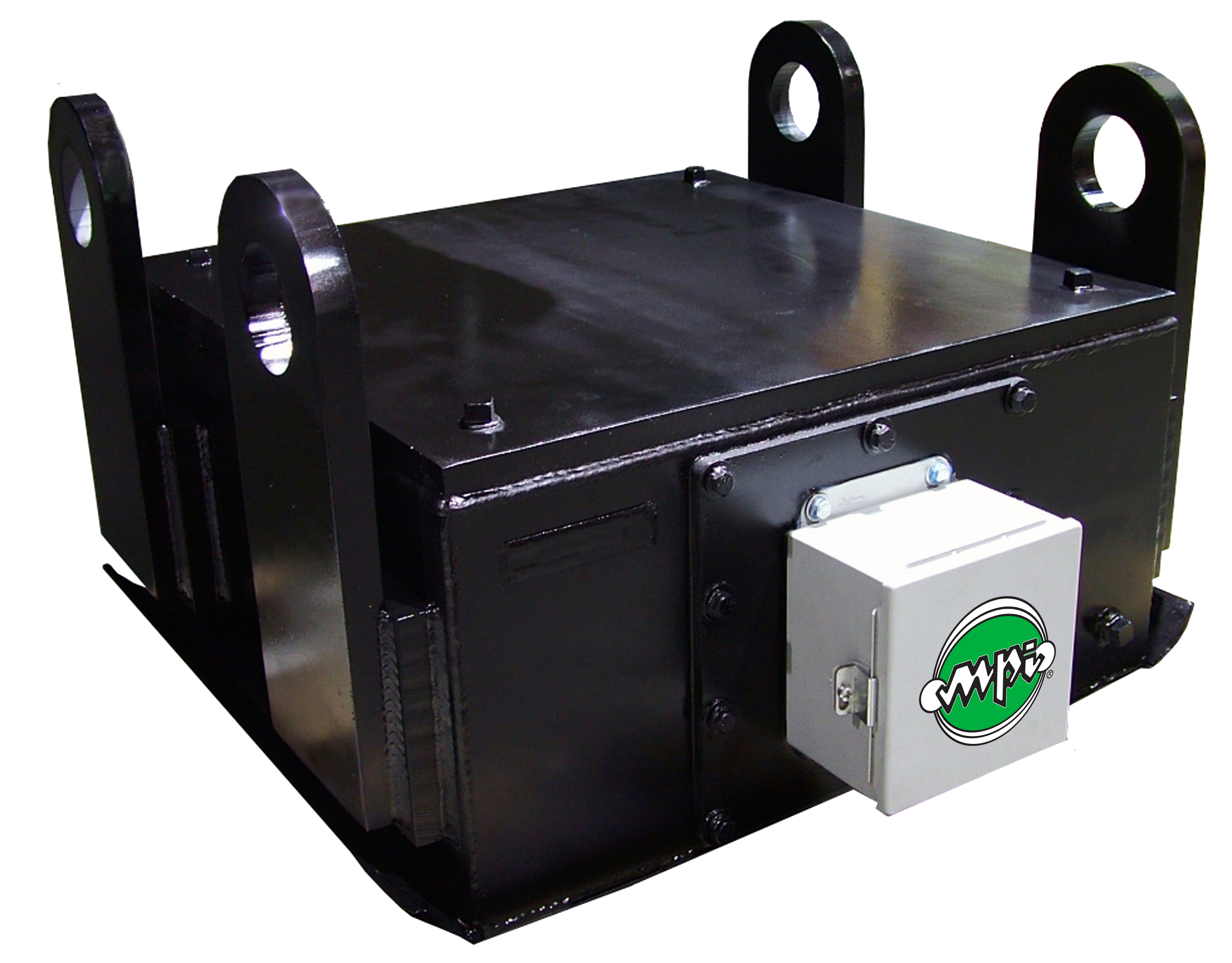

A portative electromagnet is one designed to hold the material in place. An example would be a lifting magnet.

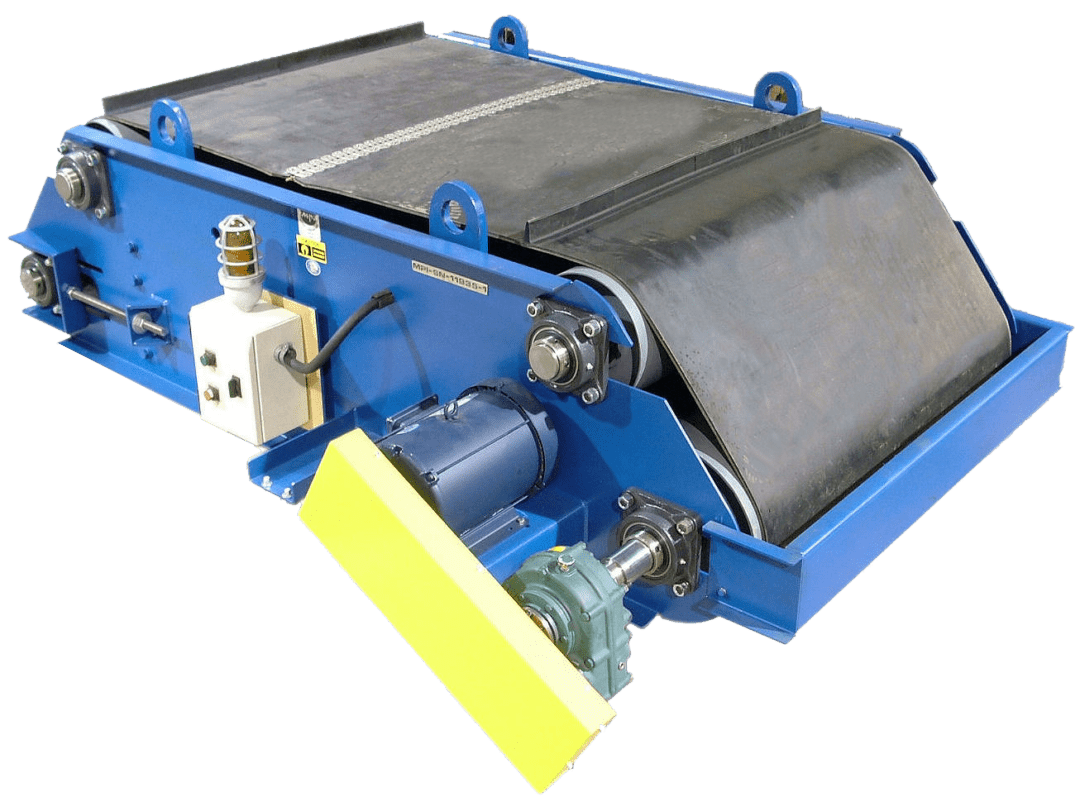

A tractive electromagnet applies a force and moves something. Magnetic separation equipment are tractive electromagnets.

At MPI, we utilize both permanent and electromagnets in our equipment. Our expertise and knowledge allow us to recommend the best magnetic separation equipment for your application.

MPI designs, manufactures, and services magnets, material handling, and electronic inspection systems. Our products are complete metal and foreign contamination control, and material handling solutions.

Here are some products we provide that utilize electromagnets:

- MPI’s Suspended Electromagnetic Cross Belt Separators produce the most effective removal of unwanted tramp metal from heavy burden depths of material being conveyed on fast-moving conveyor belts. They are ideal for separating tramp metal from wet or dry and fine or coarse conveyed materials in large or small volumes. Tramp metal extraction from product streams protects processing machinery, prevents fire or explosions caused by sparks, and improves product quality. The lower profile design of all CBS allows for installations where space is limited.

- MPI’s Electromagnetic receiving belt magnets are designed to remove both large and small types of tramp metal from product streams conveyed by vibratory bed or belts with speeds up to 700 ft. per minute.

Here are examples of how we can help you in your market.

Food manufacturing: MPI helps you achieve your food safety plan. Minimize the risk of product recall. We provide best practice know-how and equipment to detect and remove metal contaminants

Metal forming: MPI helps you reduce the trauma of production delays. We provide the most reliable parts handling and scrap removal equipment

Industrial Processing: MPI helps you convey, sort or magnetically capture metal in your production process. MPI leads the industry by engineering inventive magnetic equipment and advancing customer education. We have established the industry standard for permanent magnet separator equipment design and performance.

Contact MPI to see how we can provide you with a solution specifically to meet your needs.

How Electromagnets Can Keep You Out of Trouble

Electromagnets are simple.

Electromagnets consist of a length of conductive wire wrapped around a piece of metal.Introduce an electric current from a battery or other source and the electromagnet comes to life. A magnetic field around the coiled wire magnetizes the metal as if it were a permanent magnet.

The ability to turn the magnetic field on or off is what makes the electromagnet so useful. This is what separates them from permanent magnets like the ones holding your children’s artwork on your refrigerator.

Permanent magnets have two poles — north and south. They attract steel and iron. Like poles attract and opposite poles repel.

An electromagnet will behave in the same manner. But, the magnetic field is temporary — it only exists when an electric current is flowing. This on-demand magnetism is what makes the electromagnet so useful.

The strength of the magnetic field generated is proportional to the amount of current going through the wire. This permits control of the magnetic field and makes them useful for multiple applications.

Electromagnets are components of other electrical devices. You will find them in motors, generators, electromechanical solenoids, relays, loudspeakers, MRI machines, scientific instruments, and magnetic separation equipment.

Danish scientist Hans Christian Ørsted discovered in 1820 that electric currents create magnetic fields. British scientist William Sturgeon invented the electromagnet in 1824.

Sturgeon’s first electromagnet was a horseshoe-shaped piece of iron that was wrapped with about 18 turns of bare copper wire. When the current passed through the coil, it magnetized the iron. Stop the current, and it lost its magnetization. But, Sturgeon’s magnets were weak. An insulated wire had not yet been invented so he could only wrap a single, spaced out layer of wire around the core. This limited the number of turns.

In 1830, American scientist Joseph Henry improved and popularized the electromagnet. He used wire insulated by silk thread. This allowed him to wind many layers of wire on cores. With thousands of turns of wire, he created powerful magnets.

The first major use for electromagnets was in telegraph sounders.

There are two types of electromagnets — portative and tractive.

A portative electromagnet is one designed to hold the material in place. An example would be a lifting magnet.

A tractive electromagnet applies a force and moves something. Magnetic separation equipment are tractive electromagnets.

At MPI, we utilize both permanent and electromagnets in our equipment. Our expertise and knowledge allow us to recommend the best magnetic separation equipment for your application.

MPI designs, manufactures, and services magnets, material handling, and electronic inspection systems. Our products are complete metal and foreign contamination control, and material handling solutions.

Here are some products we provide that utilize electromagnets:

MPI’s Suspended Electromagnetic Cross Belt Separators produce the most effective removal of unwanted tramp metal from heavy burden depths of material being conveyed on fast-moving conveyor belts. They are ideal for separating tramp metal from wet or dry and fine or coarse conveyed materials in large or small volumes. Tramp metal extraction from product streams protects processing machinery, prevents fire or explosions caused by sparks, and improves product quality. The lower profile design of all CBS allows for installations where space is limited.

- MPI’s Electromagnetic receiving belt magnets are designed to remove both large and small types of tramp metal from product streams conveyed by vibratory bed or belts with speeds up to 700 ft. per minute.

Here are examples of how we can help you in your market.

Food manufacturing: MPI helps you achieve your food safety plan. Minimize the risk of product recall. We provide best practice know-how and equipment to detect and remove metal contaminants

Metal forming: MPI helps you reduce the trauma of production delays. We provide the most reliable parts handling and scrap removal equipment

Industrial Processing: MPI helps you convey, sort or magnetically capture metal in your production process. MPI leads the industry by engineering inventive magnetic equipment and advancing customer education. We have established the industry standard for permanent magnet separator equipment design and performance.

Contact MPI to see how we can provide you with a solution specifically to meet your needs.