Lift Magnets

Permanent Lifting Magnet

MPI lifting magnets make manipulation more effective without deforming or damaging the load mechanically … more

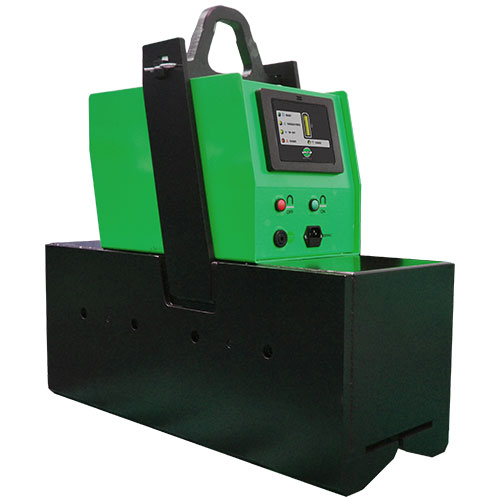

Battery Lifting Magnet BM

MPI Battery Lifting Magnets BM move flat materials using a remote control for hard to reach locations from a distance of up to 33′... more

Battery Lifting Magnet BMP

MPI Battery Lifting Magnets BMP feature a pole shape to handle round, angle sheet piles and flat materials... more

Permanent Crane Magnet

MPI permanent crane magnets handle and lift flat, clean loads from horizontal to vertical positions… more

Lifting Magnets

Lifting Magnets make moving material easier without deforming or damaging the load. MPI workholding tools are versatile, compact, and easy to operate. They replace ropes, chains, and clamps, providing more control with the strong force of a magnet.

MPI permanent lifters are the only product in the industry protected by a five-year warranty on the magnetic system. Our products are manufactured in Europe to the highest quality standards, meeting all ANSI/ASME B30.20 (safety standard) requirements.

An Air Gap test is conducted with an air gap that simulates real operating conditions to reveal true capacity. MPI offers annual lifter re-certification service to verify lifting performance, meet product specifications, and meet the requirements of your company’s annual OSHA lifting safety compliance program.

| Lifting Magnet Selection Guide |

||||

| Lifting Magnet | Permanent | Battery BM | Battery BMP | Permanent Crane |

| Included with Each Magnet |

– | 12V battery, battery charger, and remote (Controller operates from up to 33’ for safety) | 12V battery, battery charger, and remote (Controller operates from up to 33’ for safety) | – |

| Nominal Lifting Capacity Flat Material |

up to 2,000kgs/4,409lbs | up to 5,000 kg/11,023 lbs | up to 3,600kg/7,936lbs | – |

| Nominal Lifting Capacity Round Material |

up to 1,000kgs/2,204lbs | – | up to 2,200kg/4,850lbs | – |

| Horizontal Working Limit |

– | – | – | 551 lbs |

| Vertical Working Limit |

– | – | – | 176 lbs |

| Safety Factor |

3:1 | 2:1 | 2:1 | 4:1 |

| Magnetic System Warranty |

5 year | 1 year | 1 year | 1 year |

| Use |

Flat, round, and cylindrical workpieces | Flat surface loads | Flat and round surface loads | Horizontal to vertical positions, vice versa |

| MPI Difference |

Strong welded design features stainless steel lifting eye, welded to compact body, with only two recessed handle screws. Simple Easy Switch Handle switches magnet on and off easily, quickly, and safely with one hand. |

Compact LED display with battery status indicator provides audio and visual warning of low battery level. The magnet will not activate once the battery voltage drops below the safety level lifting. Large steel lifting eye with safety bail sensor. Variable Force adjusts holding force when handling a particular quantity of sheet metals from a stack, with Tip-Off for gradual slackening portion of the load. |

Compact LED display with battery status indicator provides audio and visual warning of low battery level. The magnet will not activate once the battery voltage drops below the safety level lifting. Large steel lifting eye with safety bail sensor. Variable Force adjusts holding force when handling a particular quantity of sheet-metals from a stack with Tip-Off for gradual slackening portion of the load. |

Large, lockable lifting eye prevents undesirable tilting from horizontal to vertical positions, with a lockable release lever for comfortable and safe operation. First magnetic “claw” of its kind, in compliance with UNI EN 13155 standard for handling with a crane. Unique pole configuration reduces peel-off effect for thin sheets during handling. |