MPI Magnetic Separation & Metal Sorting Solutions by Manufacturing Process: Overview and Detailed Guide

Metal control is critical at every stage of manufacturing — from raw material receiving to final inspection — to protect equipment, ensure product purity, and uphold regulatory compliance. MPI designs specialized magnetic separation and metal sorting solutions for each process step. Below is a comprehensive guide to how, where, and why to apply them.

At-a-glance Manufacturing Placements - Differences and Features

| Stage | Typical MPI Solutions | Unique Features | When to Use |

|---|---|---|---|

| Receiving | Drawer, Plate, Handheld Magnets | First defense, low maintenance | Inspecting incoming raw materials |

| Primary Processing | Suspended Magnets, Drums, Pulleys | Heavy-Duty, Large tramp removal | Bulk Flow on conveyors, chutes |

| In-Process | Drawer, Inline Pneumatic, Liquid Magnets | High-intensity, rare-earth, sanitary design | During conveying, blending, mixing |

| Finishing | Finishing Magnets, Tube Inserts | Polishes the final product quality | Before packing or filling |

| Final Inspection/Sorting | Metal Detectors, X-Ray, Automated Sorters | Finds non-ferrous & stainless sorts for recycling | QC before shipping, reclaim value |

Recommended MPI Products, Benefits and Considerations Based on Manufacturing Placement

Receiving and Incoming Material Inspection

Purpose

Capture tramp metal at the entry point to prevent contaminated raw materials from entering production.

Recommended MPI Products

- Receiving Magnets

- Manual-Clean or Quick-Clean Drawer Magnets for bag dump stations

- Plate Magnets mounted above or below conveyors infeed points.

- Inline Pneumatic Drawer Magnets for bulk powder unloading.

- Handheld Magnetic Tools

- For-spot checking totes, bins, truckloads

Key Benefits

- Prevents equipment damage downstream.

- First line of defense for product quality.

- Helps suppliers meet metal control standards at dock inspection.

Considerations

- Choose Quick-Clean designs for dusty of allergen-sensitive ingredients.

- Proper placement ensures full flow coverage.

Primary Processing (Bulk Handling & Conveying)

Purpose

Remove larger tramp metal from high-volume bulk flow before size reduction or mixing.

Recommended MPI Products

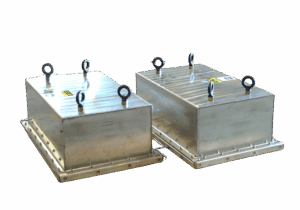

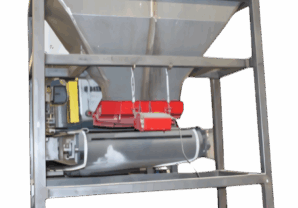

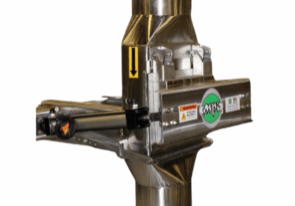

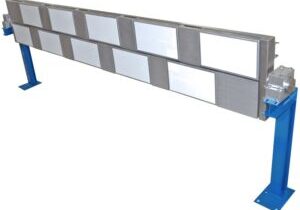

- Suspended Magnets

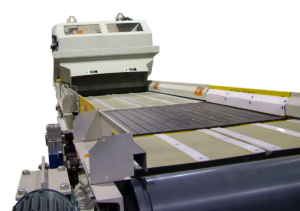

- Electromagnets or Permanent Suspended Magnets installed over belt conveyors.

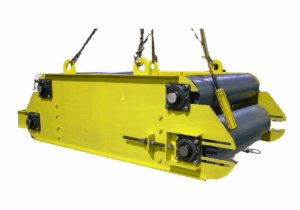

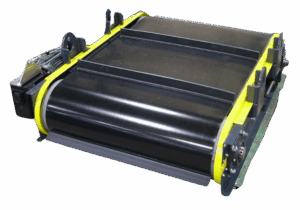

- Magnetic Drums and Pulleys

- Integrated into belt conveyors to separate ferrous pieces continuously.

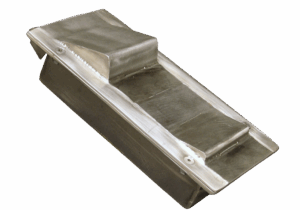

- Gravity Chute Plate Magnets

- For bulk solids moving through chutes or sprouts.

Key Benefits

- Protects crushers, grinders, and mixers from damage.

- Reduces maintenance costs and production downtime.

- Handles heavy-duty flows with rugged, self-cleaning options.

Considerations

- Select self-cleaning or manual-cleaning depending on contamination level.

- Consider environment - outdoor aggregate vs. indoor food bulk transfer.

Process Line Magnetic Separation (In-Process)

Description

Capture fine ferrous particles and wear debris generated during processing.

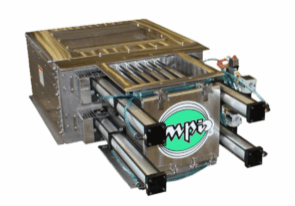

Recommended MPI Products

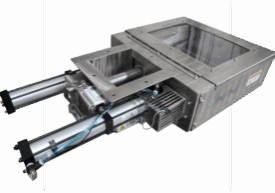

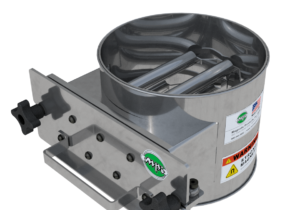

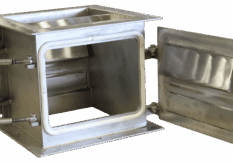

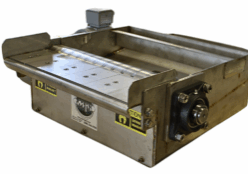

- Drawer Magnets (Manual, Quick-Clean, or Self-Clean)

- Installed in gravity lines for powders, grains, or pellets.

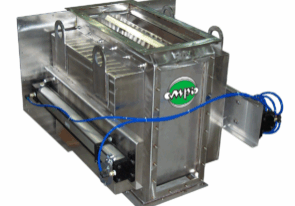

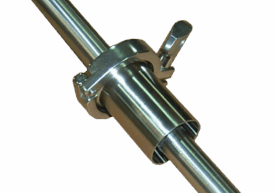

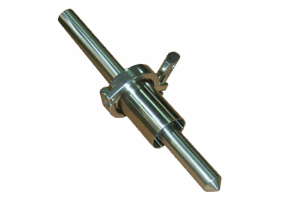

- Inline Pneumatic Drawer Magnets

- For pneumatic conveying of dry materials.

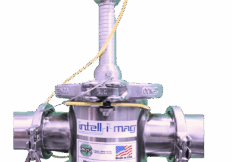

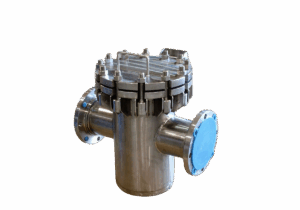

- Liquid Trap Magnets

- Tube magnets, Finger Trap, Plate Trap for liquids, sauces, and slurries.

- Magnetic Rails and Pulleys

- Keep parts aligned while conveying and capturing fines.

Key Benefits

- Maintains consistent product purity.

- Prevents contamination at blending, sifting, or extrusion sites.

- Supports regulatory compliance (FDA, HACCP).

Considerations

- Choose sanitary finishes for food, pharma, or nutraceuticals.

- Use high-intensity rare earth magnets for maximum capture of fine particles.

Finishing / Pre-Packaging

Description

Final quality control checkpoint before product enters final packaging or customer bins.

Recommended MPI Products

- Finishing Magnets

- High-intensity Drawer Magnets or Plate Magnets positioned before baggers or fillers.

- Magnetic Tube Inserts

- Drop into filter bags or strainers for extra final polish.

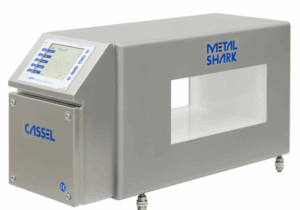

- Metal Detectors / X-Ray Inspectors

- For non-magnetic or stainless contaminants.

Key Benefits

- Ensures finished goods meet metal-free specifications.

- Protects brand reputation and reduces recall risks.

- Integrated easily into pack-off or final QC lines.

Considerations

- Combine magnetic and electronic detection for multi-layer protection.

- Choose quick-release or self-clean options for frequent sanitation.

Final Inspection and Metal Sorting

Description

Verify and remove any residual metal contamination. Sort recyclable metal for value recovery if applicable.

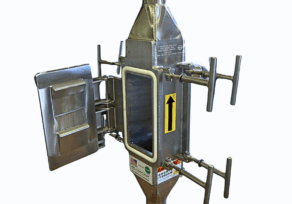

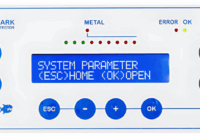

Recommended MPI Products

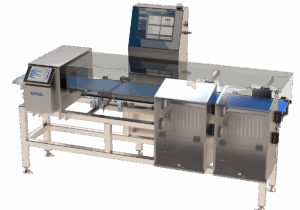

- Combination of Metal Detector and Checkweigher

- Confirms pack weight and detects stray metal.

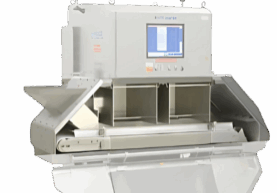

- X-Ray Inspection Systems

- Finds non-ferrous, stainless steel, or dense foreign objects.

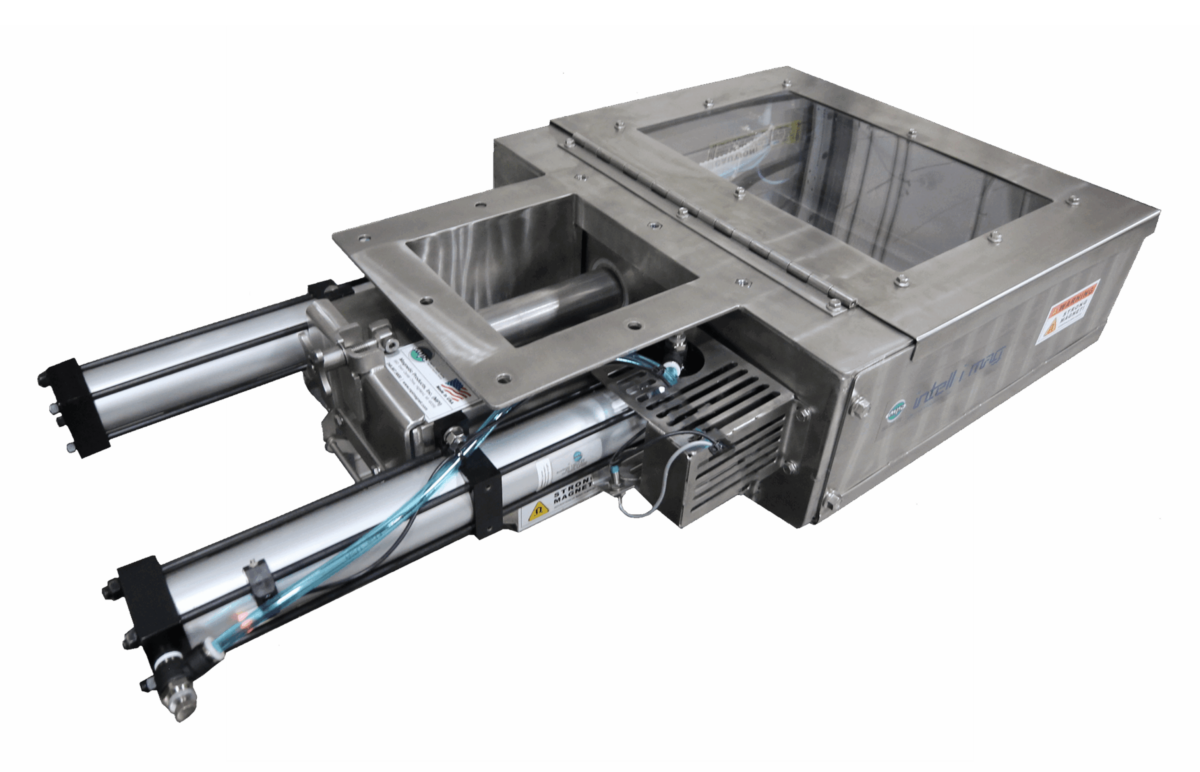

- Automated Sorting Systems

- Magnetic Drums, Eddy Current Separators for scrap and recycling lines.

Key Benefits

- Zero-defect packaging ensures compliances with customer and regulatory standards.

- Maximizes material recovery for recycling revenue.

- Supports sustainability goals by recovering usable metal fractions.

Considerations

- Match inspection sensitivity to product type and packaging material.

- Calibrate detectors regularly to maintain performance.