|

|

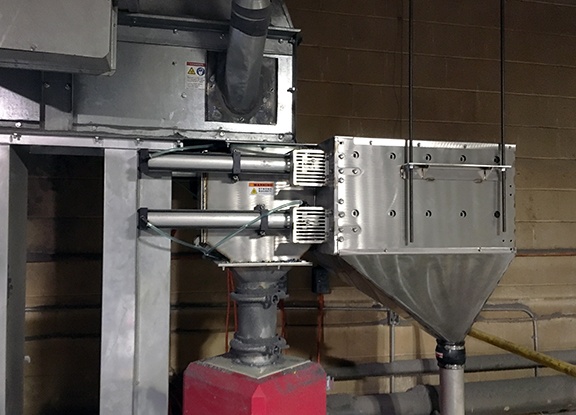

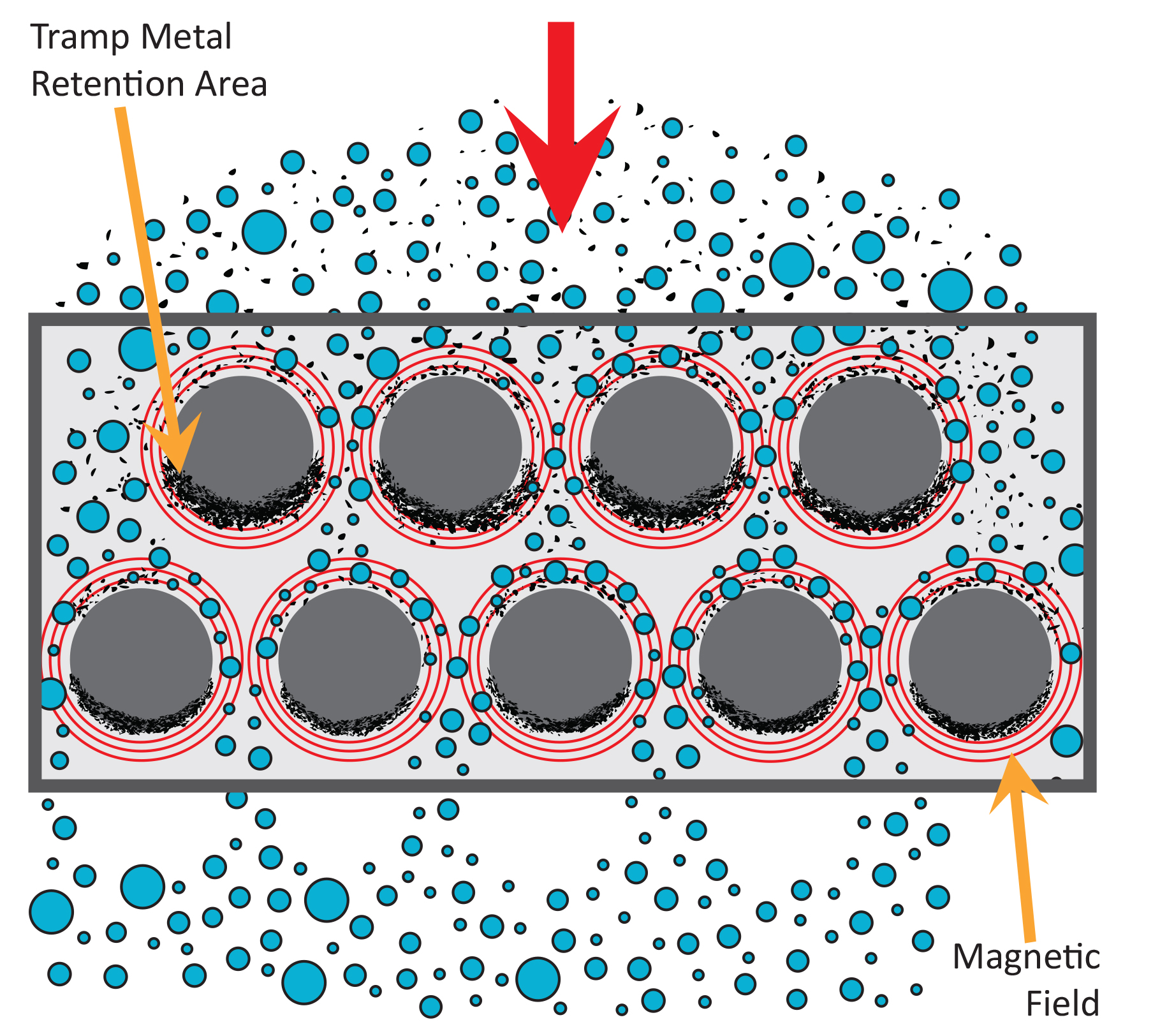

Product flows through a series of magnetic tubes designed to create an extremely effective magnetic circuit. Each row of magnetic tubes is staggered to prevent product bridging or choking and to maximize magnetic filtration. As tramp metal contaminant attaches to the magnetic tubes, the pneumatically controlled cylinders operate one double bank drawer of magnetic tubes at a time to safely remove the tramp metal from the product stream. As one drawer is in the cleaning position, the other is filtering the product stream, thus, allowing for the continuous flow of the product stream.

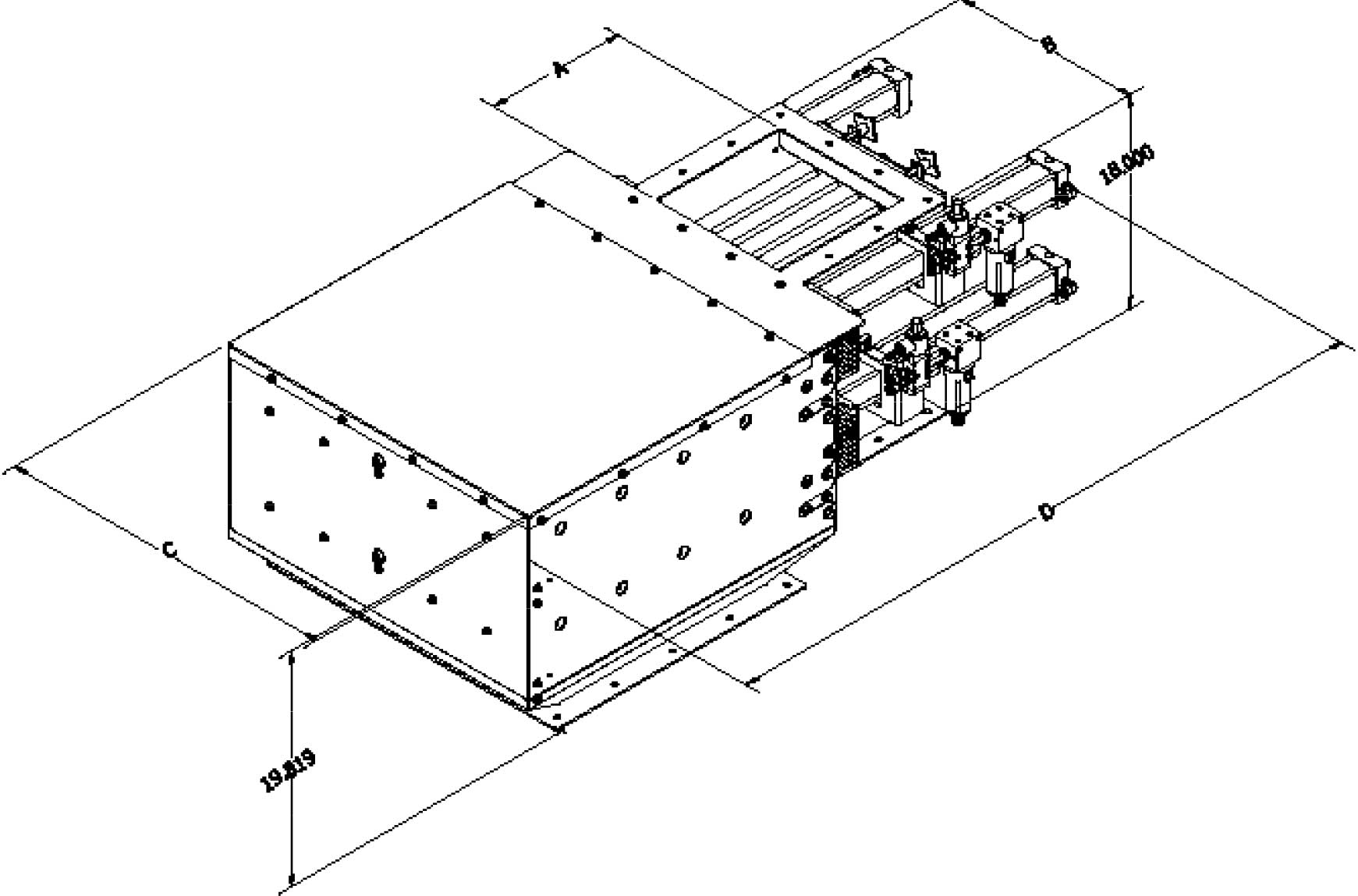

US Customary Units

| Model # | Product Flow Opening Area (A) |

Flange Width (B) |

Overall Width (C) |

Overall Length (D) |

# of Magnetic Tubes |

Approx. Weight |

| IN2 | IN | IN | IN | 4 Rows | LBS | |

| CFDMU-408-SC | 8 | 12.25 | 25.2 | 49.5 | 14 | 421 |

| CFDMU-410-SC | 10 | 14.25 | 27.2 | 53.5 | 18 | 469 |

| CFDMU-412-SC | 12 | 16.25 | 29.2 | 57.5 | 22 | 517 |

| CFDMU-414-SC | 14 | 18.25 | 31.2 | 61.5 | 26 | 565 |

| CFDMU-416-SC | 16 | 20.25 | 33.2 | 65.5 | 30 | 613 |

| CFDMU-418-SC | 18 | 22.25 | 33.2 | 69.5 | 34 | 661 |

| CFDMU-420-SC | 20 | 24.25 | 35.2 | 73.5 | 38 | 709 |

Metric Units

| Model # | Product Flow Opening Area (A) |

Flange Width (B) |

Overall Width (C) |

Overall Length (D) |

# of Magnetic Tubes |

Approx. Weight |

| CM2 | CM | CM | CM | 4 Rows | KG | |

| CFDMU-408-SC | 20.32 | 31.12 | 64.01 | 125.73 | 14 | 191 |

| CFDMU-410-SC | 25.40 | 36.20 | 69.09 | 135.89 | 18 | 212 |

| CFDMU-412-SC | 30.48 | 41.86 | 74.15 | 146.05 | 22 | 234 |

| CFDMU-414-SC | 35.56 | 46.46 | 79.25 | 156.21 | 26 | 256 |

| CFDMU-416-SC | 40.46 | 51.43 | 84.33 | 166.37 | 30 | 278 |

| CFDMU-418-SC | 45.72 | 56.42 | 89.41 | 176.53 | 34 | 300 |

| CFDMU-420-SC | 50.80 | 61.60 | 94.49 | 186.69 | 38 | 321 |

- Cleaning Method:

- Manual clean [reference datasheet DM]

- Manual quick-clean [reference datasheet DMU-QC]

- Automated self-cleaning [reference datasheet DMU-SC]

- Continuous automated self-cleaning (standard)

- Number of Tiers of Tubes:

- 200 Series with 2 tiers of tubes

- 400 Series with 4 tiers of tubes (standard)

- 600 Series with 6 tiers of tubes

- Material Construction:

- 304 Stainless Steel (standard)

- 316 Stainless Steel

- Magnetic Tubes [reference datasheet MT]:

- Ceramic

- REN Rare Earth (standard)

- Hi-G high-performance Rare Earth

- TW Thin Wall high-performance Rare Earth

- Magnetic Material Temperature:

- 400°F @ 3.5 MGO (ceramic)

- 176°F @ 52+ MGOe (rare earth) (standard)

- 248°F @ 48 MGO (rare earth)

- 356°F @ 38 MGO (rare earth)

- 662°F @ 30 MGO (rare earth)

- Tube Spacing:

- 2” horizontal and vertical spacing (standard)

- 3” (approx.) horizontal and vertical for increased flowability (recommended for products that bridge or choke) (adds 2” to OAH)

- 3” (approx.) horizontal only for increased flowability (available for height restrictions only)

- Custom configurations available

- Tube Coatings:

- Stainless steel with no coating (standard)

- Synergistic Coating [reference datasheet Synergistic Coating]

- Gasket Material:

- White silicon, FDA approved (standard)

- Buna, FDA approved

- Metal detectable blue silicon, FDA approved

- Stripper Material:

- UHMW material (standard)

- Maximum temperature: 180°F

- Hydex material Higher wear resistance compared to UHMW

- Higher maximum temperature: 221°F

- Metal detectable Hydex

- Teflon material Higher wear resistance compared to UHMW

- Higher maximum temperature: 500°F

- Transitions: Stainless steel transitions for easy installation

- Not included (standard)

- Inlet, outlet or both, configured as required for installation

- Companion Flanges: Matching companion flanges for customer to weld onto existing chute work for easy installation

- Not included (standard)

- Stainless steel companion flanges

- Carbon steel companion flanges

- Housing Vibrator: Housing mounted vibrators improve product flowability over magnetic tubes

- Mounting holes only (standard)

- Pneumatic vibrator – quantity 2

- Reed Switches: For position verification of cylinders in open and closed position

- Not included (standard)

- Quantity 2 bolt on magnetic reed switch for unit closed confirmation (120VAC/VDC 500MA)

- Quantity 4 bolt on magnetic reed switches for unit open and closed confirmation (120VAC/VDC 500MA)

- Valve Packages (Quantity 2):

- 120VAC explosion-proof rated (standard)

- 240VAC explosion-proof rated

- 12VDC explosion-proof rated

- 24VDC explosion-proof rated

- Manual lever to actuate magnet cycle

- Safety Cage Design:

- Safety cage with removable cover for magnet access (standard)

- Safety cage with hinged cover for easy magnet access

- Safety cage with hinged cover, Lexan viewing window and DESTACO latches for easy magnet access and visual drawer position monitoring

- Tramp Metal Collection Method:

- Open bottom safety cage with MPI standard flange (standard)

- Removable collection tray (split tray for sizes 16” and larger)

- Bolt-on