Description

MPI Filter Bag Magnets (FBM Series) collect ferrous metal that would otherwise be collected in the bag filter. Installing a high-performance MPI rare earth filter bag magnet inside the bag filter significantly reduces the frequency required to clean and replace bag filters. This saves money and time.

MPI’s high-performance rare earth magnetic circuit generates over 10,000 gauss on product contact areas for maximum tramp metal retention, which significantly outperforms ceramic and alnico designs. The powerful magnet reduces the tramp metal that plugs and cuts filter bags.

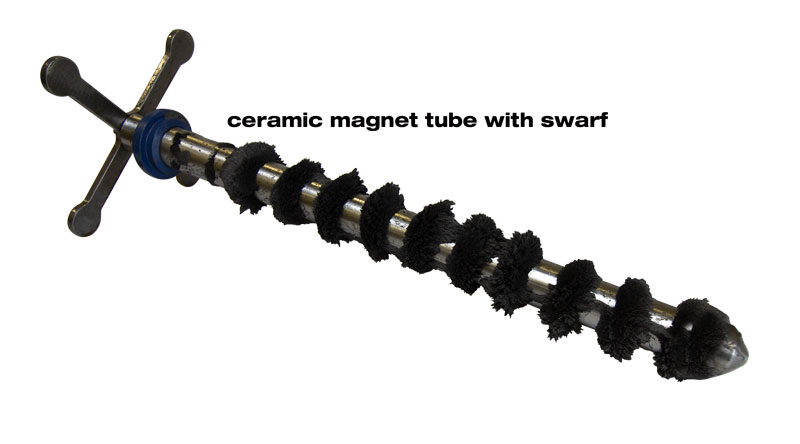

FBM’s are designed for easy installation, cleaning, and removal. Standard 316 stainless steel sturdy welded construction is durable against wear and damage. The liquid-tight, fully welded design ensures no water ingress which can damage the magnet. The full-length magnetic tube maximizes tramp metal retention. A four clover handle grip centers the magnet in the housing vessel device. The nonmetallic stripper eases routine cleaning of the magnetic tube.

Implementing a magnetic bag filtration system allows the liquid to flow around the magnetic field and capture any ferrous particles in a magnetic trap. The magnetic tube filter is then removed, cleaned, and readied for reinsertion into the bag filter to be used again.

Magnetic filtration is a commonly used method to separate particles from fluids in a wide range of applications particularly the automotive industry. The filtration process removes iron particles from products that are in liquid or slurry form. Common forms include liquid chemicals, pharmaceutical, and food products; hydraulic oils, transmission, lubricants, and coolants as well as machinery, laser cutting and milling products.