[vc_row full_width=”stretch_row_content”][vc_column][vc_column_text]

WHY CHOOSE MPI?

- We understand. You shouldn’t have to sacrifice profit margin because of inefficient or ineffective industrial sorting equipment.

- We have decades of experience. We can conduct testing prior to manufacturing, which means you can expect hassle-free, custom-built equipment.

- We know quality. We engineer and produce our product to the highest standard with best-in-class materials, so they are reliable and durable.

- MPI Customer Bill of Rights – read them here

[/vc_column_text][/vc_column][/vc_row][vc_row full_width=”stretch_row_content_no_spaces” el_class=”industrial-support-section” css=”.vc_custom_1547464190843{background-color: #0253af !important;}”][vc_column][vc_column_text]

MPI HAS SOLUTIONS

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][/vc_column][/vc_row][vc_row full_width=”stretch_row_content_no_spaces”][vc_column][vc_column_text]

[/vc_column_text][/vc_column][/vc_row][vc_row full_width=”stretch_row_content_no_spaces” css=”.vc_custom_1547467078812{background-color: #0253af !important;}” el_class=”industrial_food_section”][vc_column][vc_column_text]

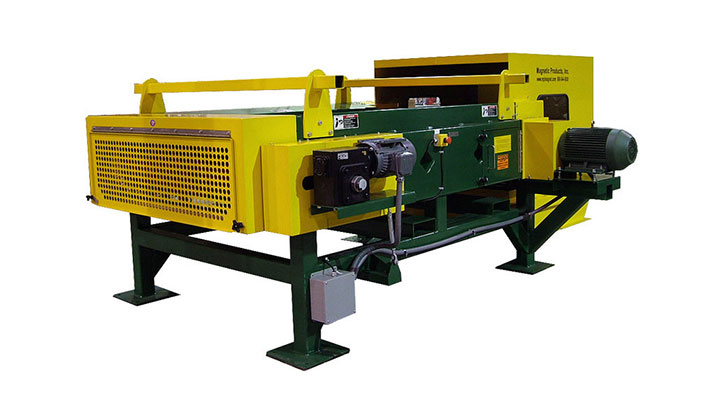

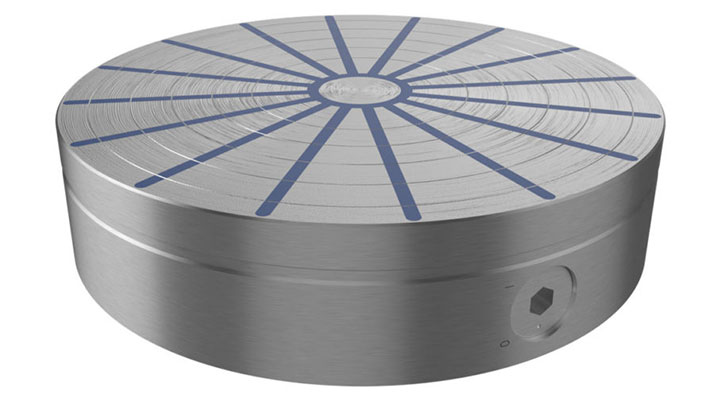

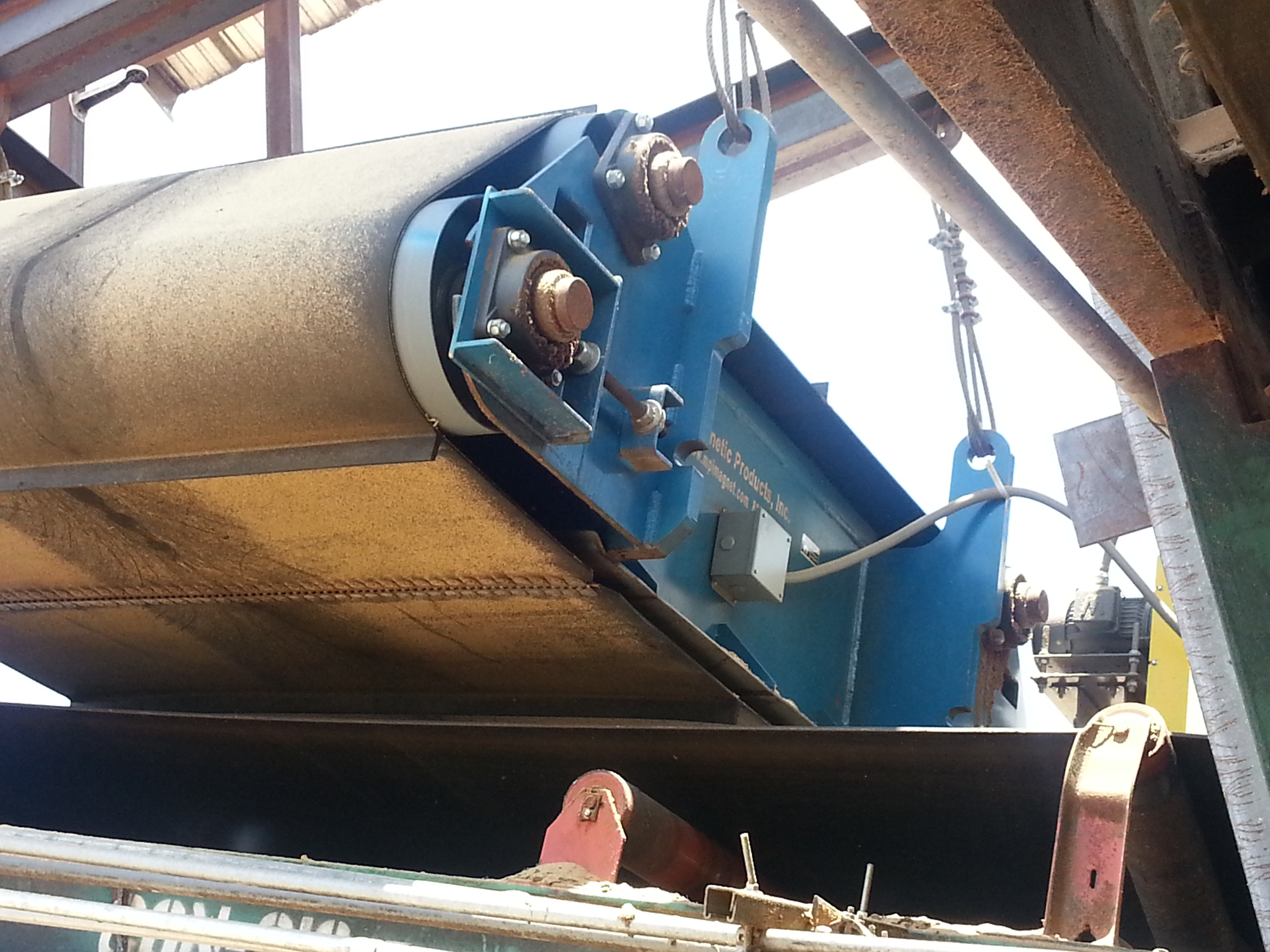

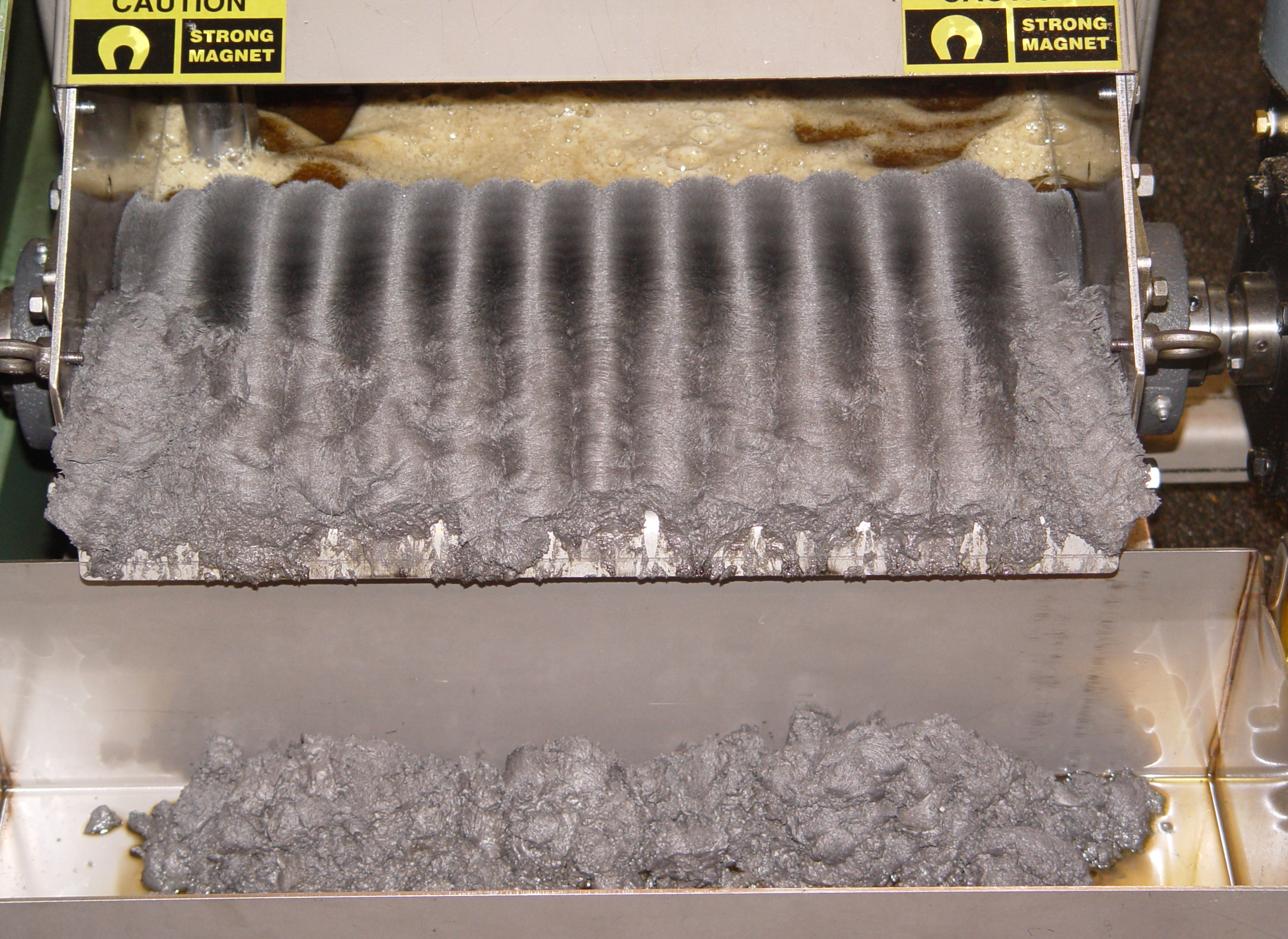

Popular Industrial Processing Products

[/vc_column_text][/vc_column][/vc_row]