Reliable Maintenance Free Conveyance

- Low frequency, smooth horizontal motion conveyor single pan systems reliably transfer scrap or parts in a horizontal motion

- Metal on metal contact points are eliminated with maintenance-free Rubber Suspension Technology (RST) bearings supporting the pan and connecting the drive. RST bearings require no grease or maintenance

- Uniform pans contain scrap or parts and reliably transfer them from conveyor to conveyor

Indestructible Pans

- Steel pans are more rigid and take less damage from scrap or parts compared to other conveyor designs

- Jams caused by scrap or parts are eliminated because pans are formed from a single sheet of steel, creating a uniform surface for the length of the conveyor

- If damaged, pans can typically be repaired or replaced in-house, reducing the need for outside vendors to help get equipment back up and running

Flexible, Modular Design

- Flexible configurations and options allow users to optimize and configure the system for their application

- The pans, drive, and pan supports are modular to scale up and down for each application and easy to replace should damage occur, maximizing uptime

Safer Operation

- Pinch points are eliminated with the single pan design and the short stroke of the drive makes the system safer to work around compared to other conveyor designs

High ROI

- Lower maintenance costs and higher uptime deliver a quick return on your investment

Turnkey Support

- MPI supports customers from initial concept to start up. Our team has the expertise to support each major step of the integration process, including onsite assessments, drawing review, component integration, scheduling for installation, installation supervision, and installation

Comparison of Linear Conveyor or Horizontal Systems for Stamping Applications

| Linear System Options |

||||

| Conveyor Type | Rate Limit | Cost | Durability | Scrap Material |

| Steel Hinge |

Unlimited | ••• | • | Any |

| Beltless Magnetic |

Limited | ••• | •• | Ferrous |

| M-10000 Shaker |

Unlimited | •• | ••• | Any |

- Compared to traditional steel belt conveyor designs, the MPI M-10000 Linear Shaker System reduces metal on metal contact points in the conveyor design by over 99%. Metal on metal contact points are a primary cause of wear in conveying systems. When using RST bearings, there are only two metal on metal contact locations: internal to the enclosed drive system and where the scrap contacts the pans. Forming pans from a single sheet or plate of steel and flush mounting them together reduces the number of places where scrap metal can cause jams or conveyor damage. In addition, scrap moves without the use of paddles or cleats, which can break and require repair. This robust design results in years of maintenance free operation.

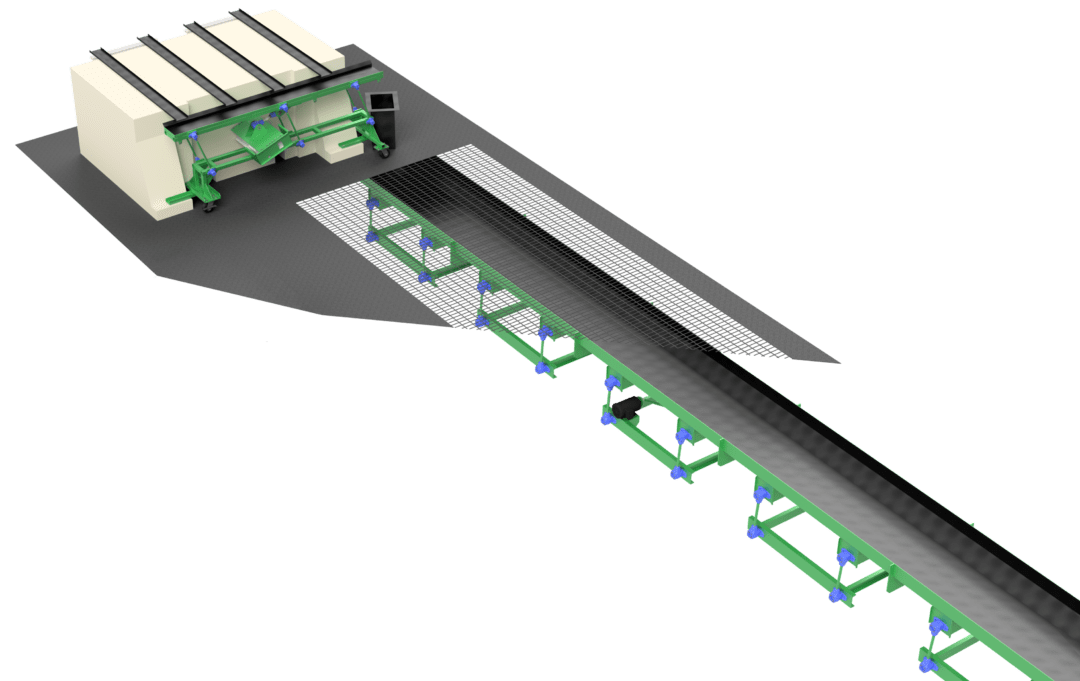

The MPI M-10000 horizontal motion conveyor uses modular sections of pans assembled together to form a continuous single pan. It is driven by a single section that has a drive and is connected to the pan above. This drive creates a slow, low frequency movement with a quick return that drives material forward. Utilizing a single continuously formed pan assembly ensures the scrap metal is contained while also eliminating jams caused by pinch points.

The shaker pans are supported by maintenance-free Rubber Suspension Technology (RST) bearings. Unlike traditional bearings, RSTbearings use pressed rubber around a square shaft, which requires no grease. This gives the bearing several functions in one, including a torsion spring, pivot bearing, and anti-vibration mount. The design also eliminates metal on metal contact points, which are friction locations that are known to create wear or maintenance issues.

The drive is a scaled-up design from MPI’s trusted and patented M Series shaker conveyor line. The shaker system operates almost silently and uses a high efficiency motor to reduce operating costs. It is designed to transfer materials at a rate of up to 15 FPM.

The M-10000 series horizontal motion conveyor is different than traditional fiber leaf spring vibratory conveyors or electromagnetic vibratory conveyors that vibrate product at a high frequency. MPI’s horizontal motion conveyor uses a low frequency, smooth motion to move the product.

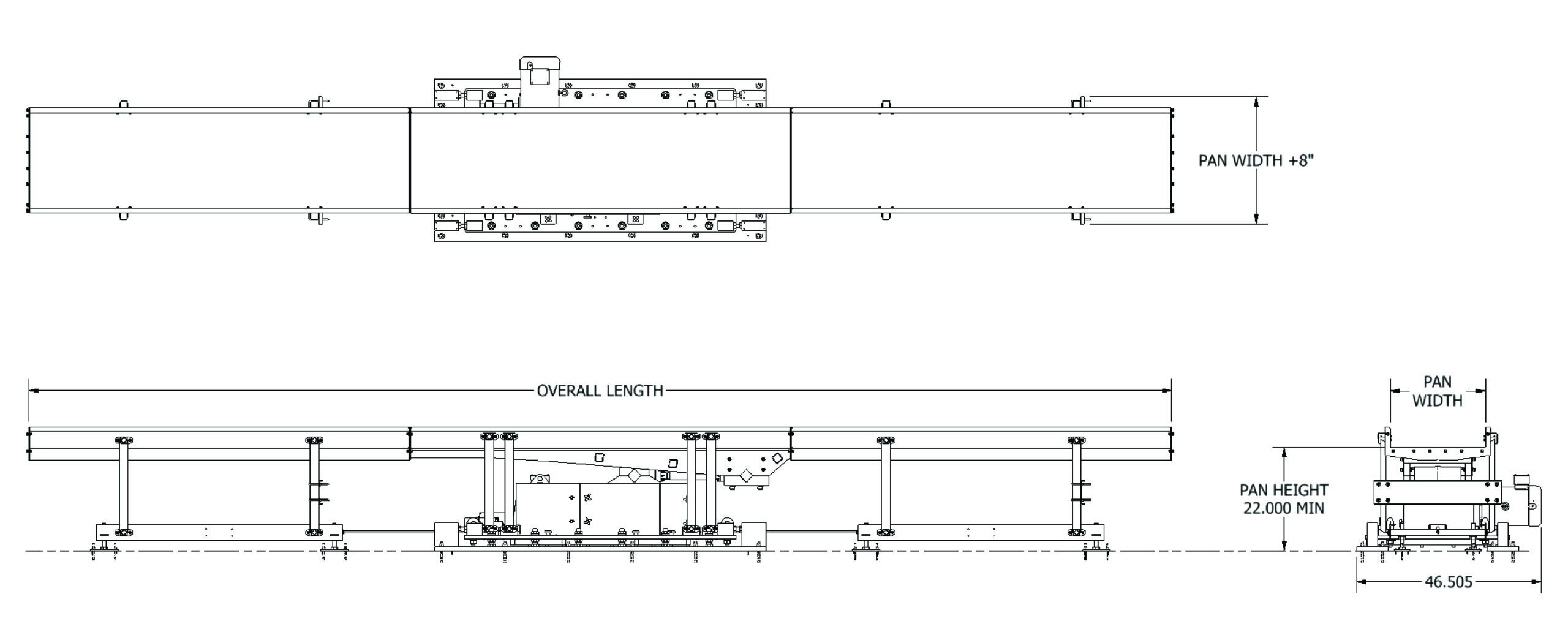

Most key dimensions called out in the above drawing are based on system configurations from the Options tab. During the assessment process, MPI will evaluate your plant system layout and help configure the system to fit into your installation location.

Most key dimensions called out in the above drawing are based on system configurations from the Options tab. During the assessment process, MPI will evaluate your plant system layout and help configure the system to fit into your installation location.

Submit an RFQ for a Floor Mounted Electric Shaker Conveyor.

Drive System: Patented M-10000 Series shaker drive system module including motor, gear case and cam mounted to base plate to drive system, as configured below.

Assembled Pan Length: The maximum length of the shaker pan is dependent on the size, shape, material, and scrap rate being transferred on the pan. Below are general guidelines for maximum lengths.

- Up to 250 ft. based on pan width of 24”

- Up to 200 ft. based on pan width of 36”

Pan Size: Pan sizes and shapes can be configured for the application as required. Below are the standard shaker pan sizes and shapes available. Overall pan section / width of the system is pan width + 8”. MPI recommends an OSHA compliant 18” walkway on one side of the shaker pan system. Minimum recommended pit width = pan width + 8” + 18”. Note that drive section will always require a minimum 48” width.

- Troughed pan shape 24” wide pan x 6” deep

- Troughed pan shape 24” wide pan x 12” deep

- Troughed pan shape 36” wide pan x 6” deep

- Troughed pan shape 36” wide pan x 12” deep

- Rectangular pan shape 24” wide x 6” tall side guides for low profile installation

- Rectangular pan shape 36” wide x 6” tall side guides for low profile installation

- Custom pan shape as required for application

Pan Material: MPI offers different pan materials and configurations to ensure reliable scrap transfer rates and abrasion resistance as required by the application.

- Manufactured from 10-gauge carbon steel (standard)

- Manufactured from 10-gauge stainless steel

- Manufactured from 7-gauge manganese steel for increased impact and wear resistance

- Manufactured from 10-gauge carbon steel with replaceable wear liner manufactured from optional material such as rigidized sheet, AR sheet or composite materials as required for the application

Bearings: Bearings support the shaker pan and are installed on the top and bottom of a support arm that connects at the pan and subframe. Maintenance free Rubber Suspension Technology (RST) bearings (included).

Conveyor Speed: The horizontal motion of the conveyor system has a maximum design speed but can run at lower speeds if needed. Maximum design speed is 15 FPM.

Pan Height: Shaker conveyor pan height is flexible based on the configuration required and stack-up height of multiple systems.

- 22” complete with subframe (standard)

- Low profile custom design without subframe available

- Raised pan height to accommodate customer specified pan height with additional subframe supports

Motor Installation Location: MPI offers multiple drive motor installation locations for flexibility of installation into existing plants.

Motor: Motor horsepower ratings are sized for the application and available in multiple input voltages as required by the installation location.

Grease System: Installed on main drive for maintenance free lubrication.

- 2-year auto lube grease pack to reduce maintenance requirements

Paint:

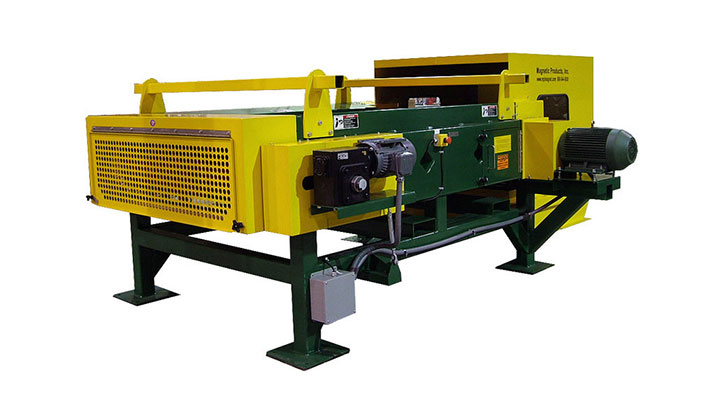

- Carbon steel components painted MPI Green, guards paint safety yellow (standard)

- Carbon steel components painted grey, guards paint safety yellow

- Customer specified color, RAL # required

Controls: MPI offers standard control packages for the shaker system. Controls can be customized if required for the application.

Safety Devices: For added safety, MPI recommends installing an E-stop pull cord system around the accessible sides of the shaker system.

Motion Control Monitoring: Motion control systems are integrated into the control system to ensure movement to the shaker system.