|

|

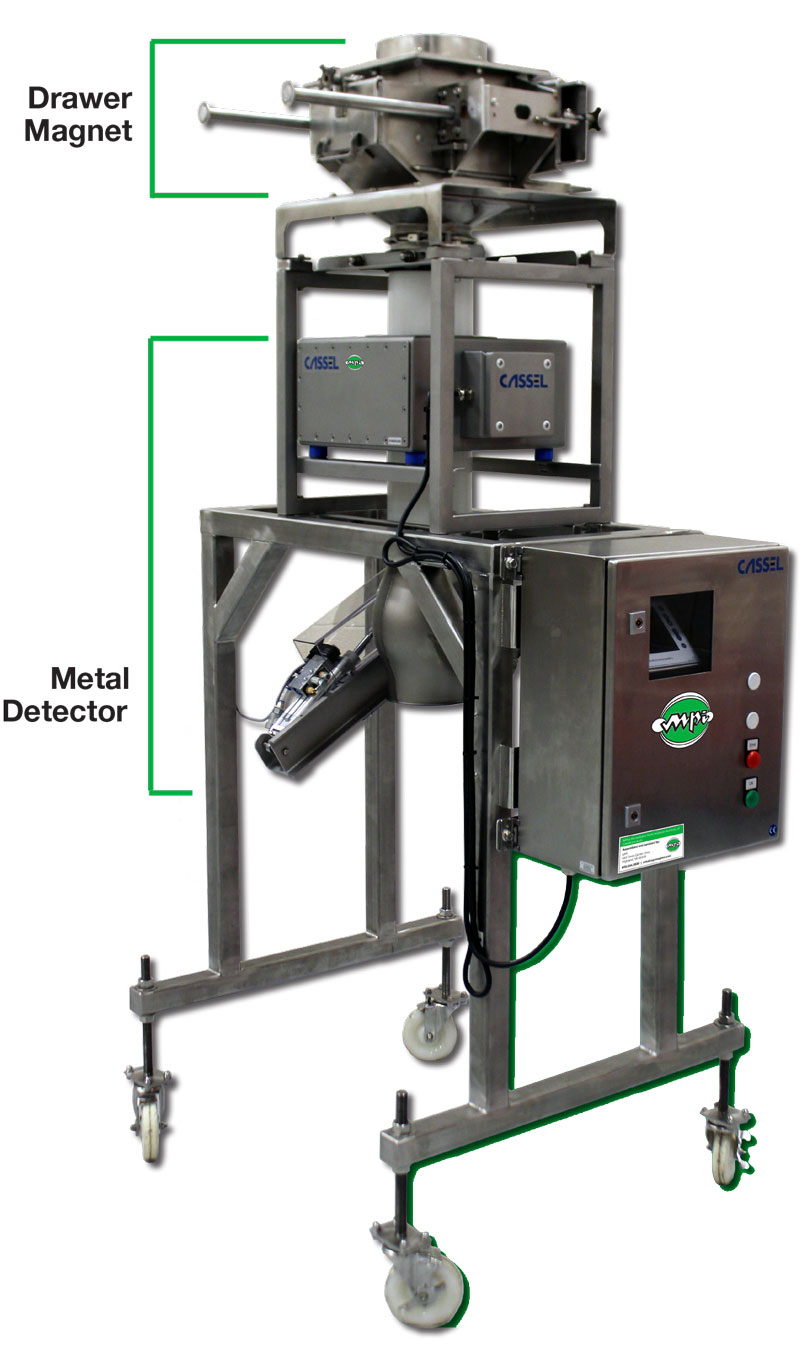

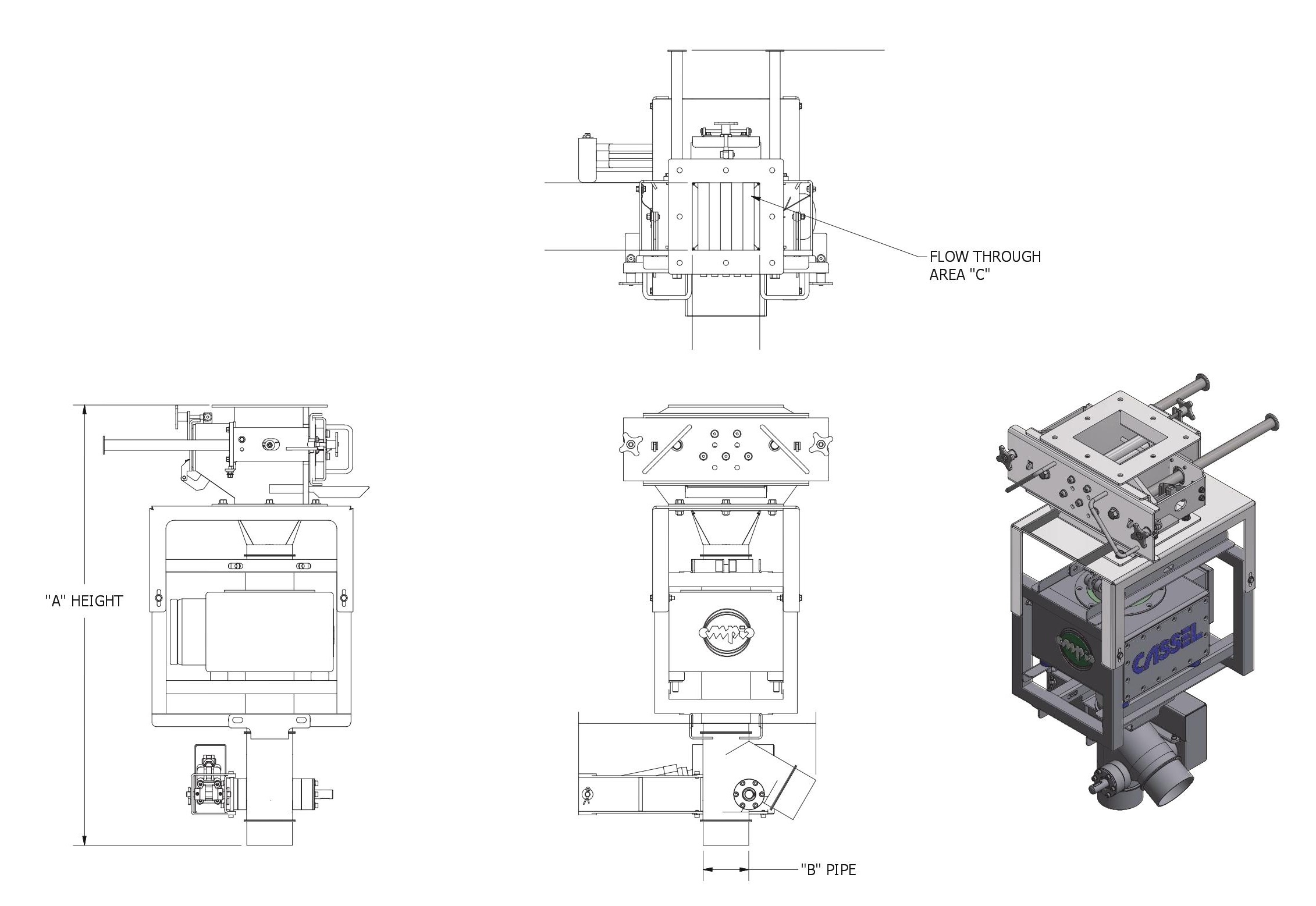

Designed for use in gravity-feed pipes to monitor for metal contaminants in continuous-flowing granules or powders such as sugar, flour, corn meal, or spices, the Pro-Tector’s integrated drawer magnet provides maximum magnetic separation of contaminants. Product first flows through the drawer magnet, which is located at the top of the unit, and then ferrous-free product continues through a gravity-feed metal detector.

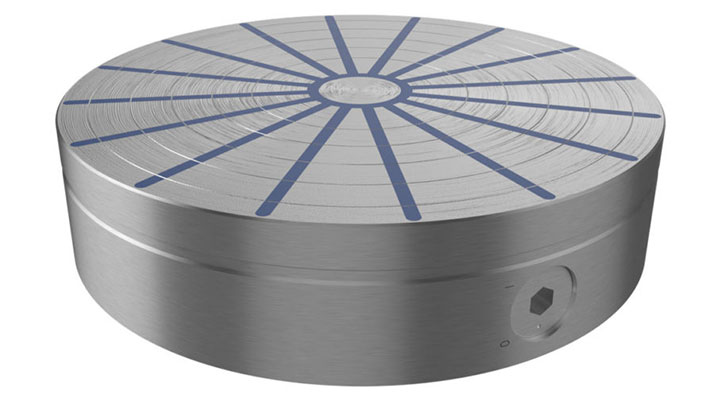

The Pro-Tector’s integrated drawer magnet employs twin layers of rare-earth magnetic tubes to provide maximum magnetic separation of metal contaminants, and its quick-clean feature allows the operator to clean the unit in under ten seconds.

Extremely reliable and easy to use, the Pro-Tector’s integrated metal detector features a straightforward operating system that quickly guides the user through set-up and operation.

US Customary Units

| Pro-Tector Model # | Overall Height w/Reject (A) | Flow Rate (Based on DMU) |

Pipe Diameter (B) |

Flow Through Area | Sensitivity from FE |

DMU Model # |

GF Model # |

|

| FT3/HR | Gallons/Hr | |||||||

| Pro-100 | 39.2″ | 300 | 2,244 | 3.93 in. | 36 in2 | <0.5″ | DMU-206-QC | GF-100 |

| Pro-150 | 49.0″ | 600 | 4,488 | 5.90 in. | 64 in2 | <0.6″ | DMU-208-QC | GF-150 |

| Pro-200 | 63.4″ | 1,350 | 10,098 | 7.87 in. | 100 in2 | <1.2″ | DMU-210-QC | GF-200 |

Metric Units

| Pro-Tector Model # | Overall Height w/ Reject (A) | Flow Rate (Based on DMU) |

Pipe Diameter (B) |

Flow Through Area | Sensitivity from FE |

DMU Model # |

GF Model # |

|

| M3/HR | L/HR | |||||||

| Pro-100 | 99.47cm | 8.50 | 8,494 | 9.98cm | 232.3cm2 | <1.27cm | DMU-206-QC | GF-100 |

| Pro-150 | 124.47cm | 16.99 | 16,989 | 14.99cm | 412.9cm2 | <1.52cm | DMU-208-QC | GF-150 |

| Pro-200 | 161.01cm | 38.22 | 38,225 | 19.99cm. | 645.2cm2 | <3.05cm | DMU-210-QC | GF-200 |

USDA certified drawer magnet available

- SHARKNET® software

- Monitor real-time inspection results and actively manage product inspection equipment from a central computer

- Enables automatic downloading of data documentation to a Windows-based PC

- Support required compliance with: HACCP-SQF 2000-BRC-GMP-IFS5-FSSC 22000/PAS 220

- Remote maintenance capability by operators and Cassel technicians

- All data is stored in an SQL database for easy export or integration if needed

- Pro-Tector for Liquid Systems

- For more information on this system contact MPI

- Pro-Tector for Pneumatic Systems

- For more information on this system contact MPI