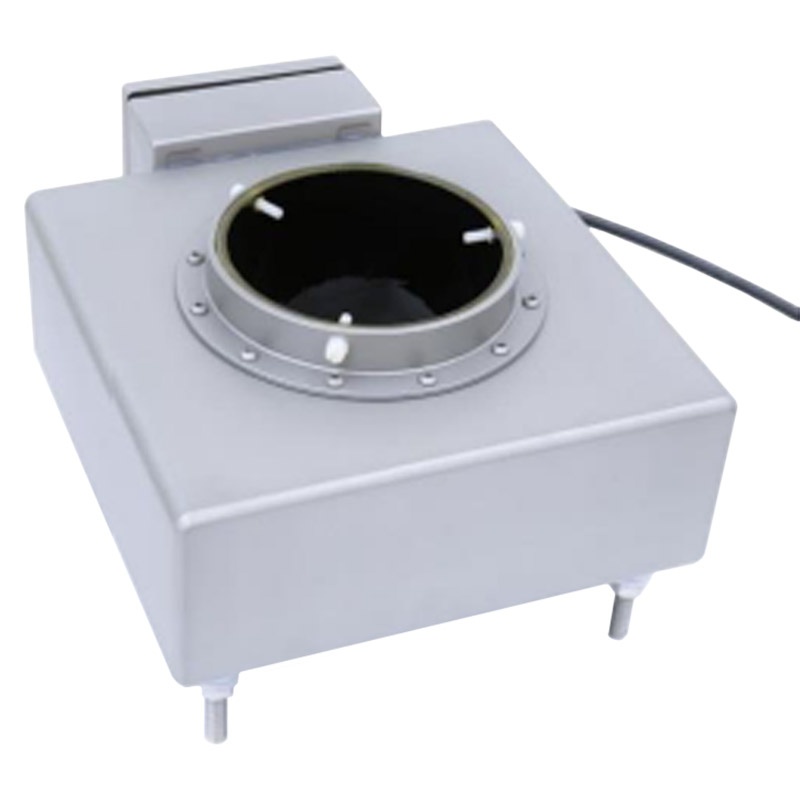

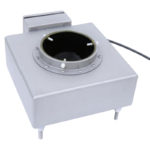

Gravity Packaging Throat Metal Detector

- Full 2-year warranty on the complete system–giving you peace of mind

- Hygienic food industry design-ensures compliance with good manufacturing principles

- Harsh environment rating as standard on sensor head–ensures the unit remains stable whatever the environment

- Semi-flexible aperture lining–resists thermal shock due to temperature change and protects the sensor for maximum operating life and minimum down time

- All-solid-state electronics housed on one mainboard–ensures years of reliable performance offering the lowest cost of ownership on the market

- Intuitive menu structure–simple operation for reliable performance, no expensive service calls to adjust settings

- Full HACCP compliance–demonstrates your due diligence, ensures you and your customers are protected

- Full pre-sale applications and custom design service–making sure we provide the right solution first time

- Satisfaction guarantee–put simply, the unit will perform as specified or we will take it back for a full refund

Once installed, bulk material falls through the metal detector. If any metallic contaminant, magnetic or non-magnetic is detected, the metal detector alerts the reject that will remove the contaminated package after it passes the fill and/or seal stages (depending on application installation).

Unit dimensions: L 12.125” x W 12.125” x H 5.9”

Product Flow Opening Diameter: 3.9”

Control Electronics

Digital signal processor, digital noise filter, digital balance control, digital frequency control with synthesizer, Power-Drive-Transmitter-Circuit, suitable with multi-frequency sensors, powerful graphics processing unit

Input Signals

8 free configurable, 24 V DC, e.g.: reject confirmation, air pressure monitor, conveyor belt control

Output Signals

2 potential free: Metal and Error

8 free configurable, 24 V DC, e.g.: pusher magnetic valve, optic/acoustic alarm

Measuring Method

Inductive; multi-channel operation, balanced receiver coils

Metal Detection

Ferrous, non-ferrous (e.g. aluminum or copper) and stainless steel

Product Compensation

120 storage spaces, compensation performed automatically, with Teach-Assistant

Protection Type

IP65; with Option LPW: IP66; with Option HPW: IP67

Environment

Standard: temp. -10°C to +40°C, rel. humidity 30 to 85% not condensing; Options: -40°C or +55°C

Product Temperature

-30°C to +60°C, Option: -40°C to +120°C

Power Supply

Single-Phase 110 – 240 VAC, 50/60 Hz, fuse 10 A (slow), typ. power consumption 20W, max. 60W

Interfaces

RS232, USB, optional Ethernet and WLAN for HACCP- and IFS-documentation

Maintenance

Maintenance-free, sensor calibrates itself automatically and continuously

Diagnosis

Integrated diagnostic software, automatic selftest

Best possible sensitivities:

Fe 0.8 NFe 1.1 SS 1.3 Ø mm @ 300kHz:

- SHARKNET® software

- Monitor real-time inspection results and actively manage product inspection equipment from a central computer

- Enables automatic downloading of data documentation to a Windows-based PC

- Support required compliance with: HACCP-SQF 2000-BRC-GMP-IFS5-FSSC 22000/PAS 220

- Remote maintenance capability by operators and Cassel technicians

- All data is stored in an SQL database for easy export or integration if needed