|

|

|

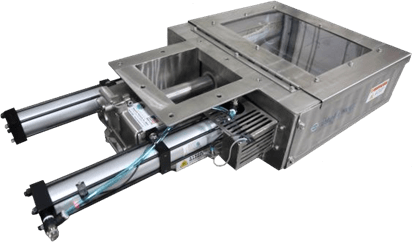

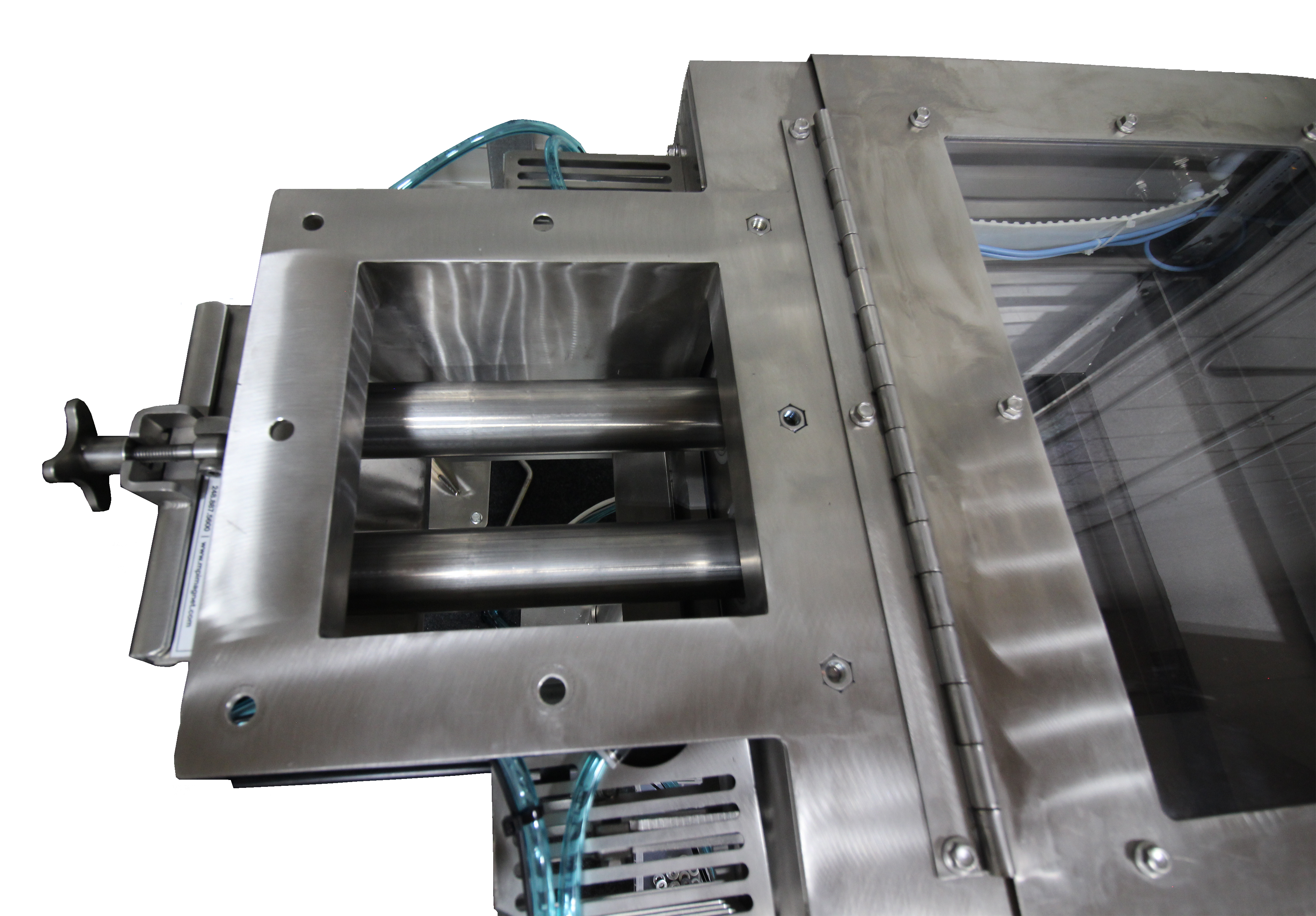

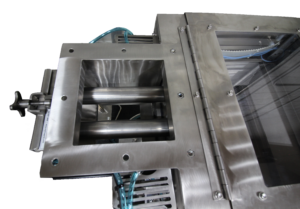

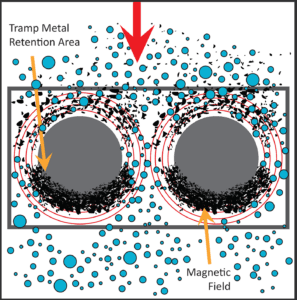

The product stream flows through a series of 2” diameter magnetic tubes designed to create an extremely effective magnetic circuit. The row of magnetic tubes prevent bridging or choking of the product stream and maximize magnetic filtration as product flows through the housing. Tramp metal contaminants are attracted to the magnetic tubes. The pneumatically operated cleaning system safely removes tramp metal from the product stream to a disposal area outside the product flow area.

The product stream flows through a series of 2” diameter magnetic tubes designed to create an extremely effective magnetic circuit. The row of magnetic tubes prevent bridging or choking of the product stream and maximize magnetic filtration as product flows through the housing. Tramp metal contaminants are attracted to the magnetic tubes. The pneumatically operated cleaning system safely removes tramp metal from the product stream to a disposal area outside the product flow area.

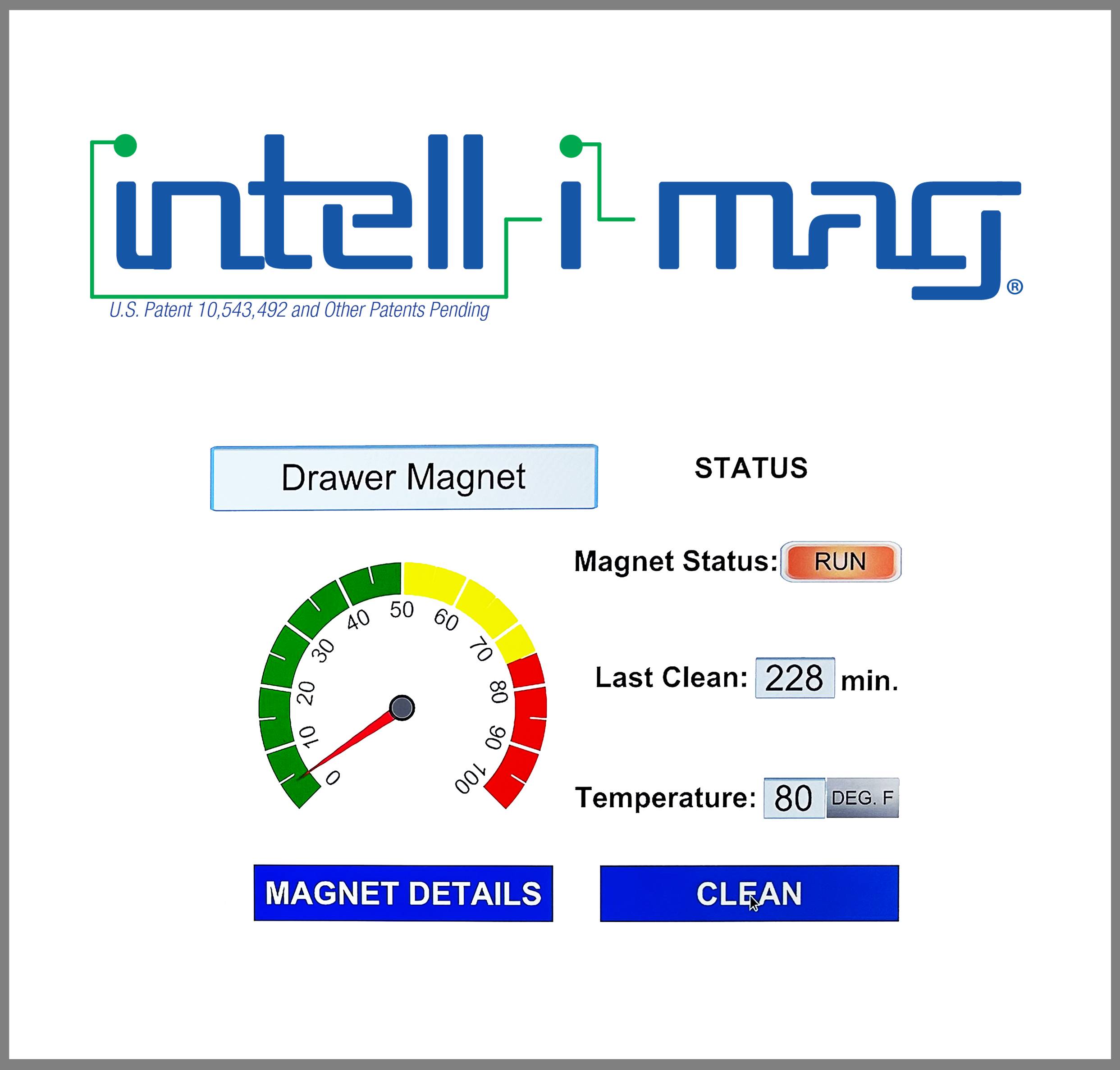

With Intell-I-Mag® sensors embedded into the system, the separator can monitor magnet saturation levels and temperatures in real-time.

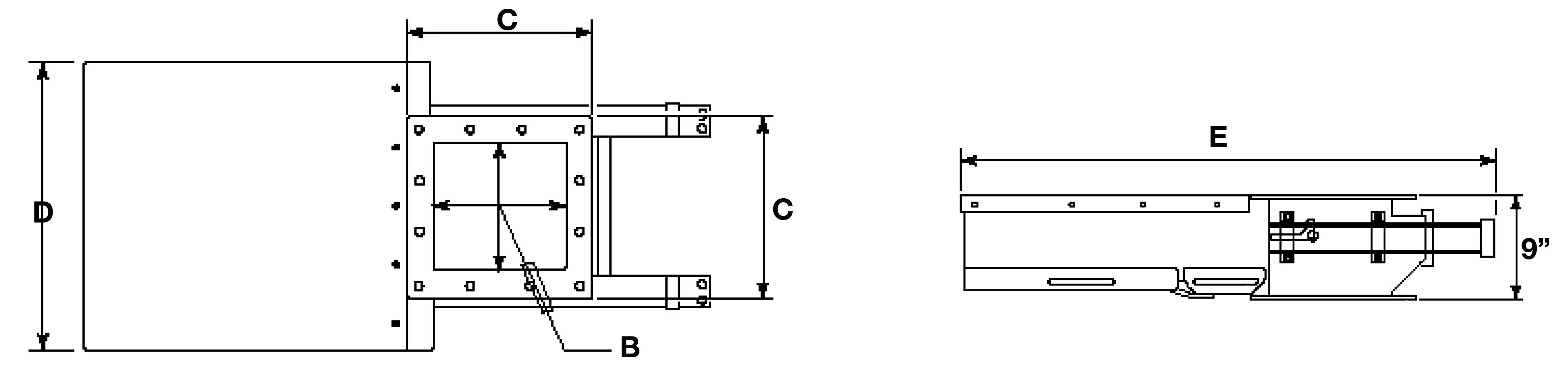

US Customary Units

| DRAWER MAGNET MODEL # | DMU Opening (B) | Number of Tubes | Flange Width (C) |

Overall Width (D) |

Overall Length (E) | Unit Approx. Weight | Flow Rate |

| IN | NO | IN | IN | IN | LBS | FT3/HR | |

| DMU-208-SC | 8 x 8 | 2 | 12.25 | 22.75 | 43 | 170 | 600 |

| DMU-212-SC | 12 x 12 | 3 | 16.25 | 26.75 | 47 | 190 | 2,400 |

| DMU-216-SC | 16 x 16 | 4 | 20.25 | 30.75 | 51 | 230 | 3,750 |

| DMU-220-SC | 20 x 20 | 5 | 24.25 | 34.75 | 55 | 300 | 6,337 |

| DMU-224-SC | 24 x 24 | 6 | 28.25 | 38.75 | 59 | 330 | 9,600 |

Metric Units

| DRAWER MAGNET MODEL # | DMU Opening (B) | Number of Tubes | Flange Width (C) |

Overall Width (D) |

Overall Length (E) | Unit Approx. Weight | Flow Rate |

| CM | NO | CM | CM | CM | KG | M3/HR | |

| DMU-208-SC | 20 x 20 | 2 | 31 | 58 | 109 | 77 | 16.99 |

| DMU-212-SC | 31 x 31 | 3 | 41 | 68 | 120 | 86 | 67.96 |

| DMU-216-SC | 41 x 41 | 4 | 51 | 78 | 130 | 104 | 106.18 |

| DMU-220-SC | 51 x 51 | 5 | 61 | 88 | 140 | 136 | 179.44 |

| DMU-224-SC | 61 x 61 | 6 | 71 | 98 | 150 | 149 | 271.84 |

Other sizes are available upon request.

Intelligence with Intell-I-Mag®:

- Intell-I-Mag® ready (upgradable)

- Intell-I-Mag® Included

Cleaning Method:

- Automated self-cleaning (standard)

- Continuous automated self-cleaning

Number of Tiers of Tubes:

- 100 Series with 1 tier of two-inch tubes (standard)

- 200 Series with 2 tiers of two-inch tubes (continuous automated self-cleaning design only)

Magnetic Tubes [reference datasheet MT]:

- Hi-G high-performance Rare Earth

Diverters: Diverters slow the product down through the separator and direct product onto the magnetic tubes for increased separation efficiency.

- Included (standard)

- Not included (optional for products that bridge or choke)

Maximum operating temperature: 221 F

Maximum particle size: ½”

Maximum target tramp metal size: 1”

Stripper Material:

- UHMW material (standard) Maximum temperature: 180°F (82°C)

- Hydex material with high wear resistance and temperature, maximum temperature: 221°F (105°C)

- Metal & x-ray detectable Hydex material with high wear resistance and temperature, maximum temperature: 221°F (105°C), color: blue

Self-Clean Package:

- (2) Pneumatic cylinders prepped for reed switches – 80 PSI input. (standard)

- (2) hydraulic cylinders

Reed Switches: For position verification of cylinders in open and closed position.

- Not included (standard)

- Quantity 1 bolt-on magnetic reed switch for unit closed confirmation (120VAC/VDC 500MA)

- Quantity 2 bolt-on magnetic reed switches for unit open and closed confirmation (120VAC/VDC 500MA)

Valve Package:

- 120VAC explosion-proof rated (standard)

- 240VAC explosion-proof rated

- 12VDC explosion-proof rated

- 24VDC explosion-proof rated

- A manual lever to actuate magnet cycle

Transitions: Stainless steel transitions for easy installation.

- Not included (standard)

- Inlet, outlet or both, configured as required for installation

Safety Cage Design:

- Safety cage with removable cover for magnet access (standard)

- Safety cage with hinged cover for easy magnet access

- Safety cage with hinged cover, Lexan viewing window, and DESTACO latches for easy magnet access and visual drawer position monitoring

Tramp Metal Collection Method:

- Open bottom safety cage with MPI standard flange (standard)

- Removable collection tray (split tray for sizes 16” and larger)

- Bolt-on tramp iron collection transition to 4” pipe with sock bead to attach collection pipe or bag

Rack and Pinion System: Large drawers, adhesive and abrasive products can benefit from the added alignment provided by the rack and pinion system. The RP system provides smooth and jam-free cleaning of the magnetic tubes ensuring that all magnet tubes travel the exact same distance, at the same time, from left-to-right, top-to-bottom, resulting in reduced system wear and improved magnetic tube cleaning.

- Not included (standard)

- Included

Internal Drawer Support: Provides drawer support when cycling and mechanically fastens tubes together.

- Not included (standard on sizes 16” and smaller)

Included (standard on all sizes 18” and larger)

Material Construction:

- 304 Stainless Steel (standard)

- 316 Stainless Steel

Magnetic Material Temperature:

- 176°F (80°C) @ 52+ MGOe (rare earth) (standard)

Tube Coatings:

- Stainless steel with no coating (standard)

- Synergistic Coating

Gasket Material:

- White silicone, FDA approved (standard)

- Buna, FDA approved

- Metal detectable blue silicone, FDA approved

Companion Flanges: Matching companion flanges for a customer to weld onto existing chute work for easy installation.

- Not included (standard)

- Stainless steel companion flanges

- Carbon steel companion flanges