|

|

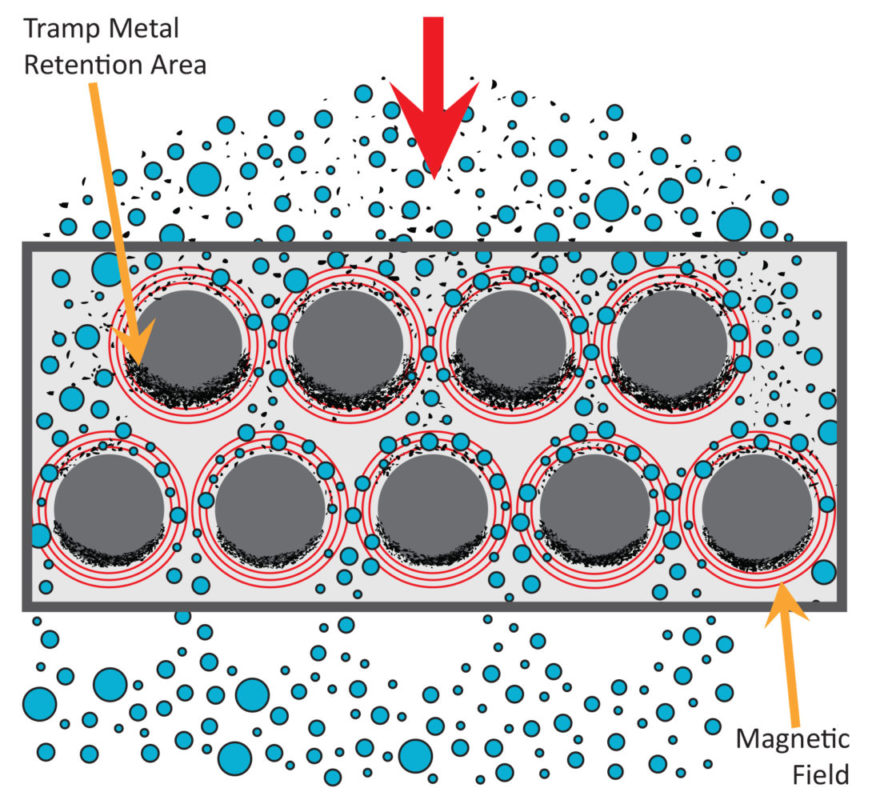

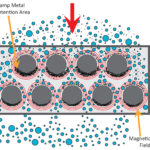

The product stream flows through a series of 1” diameter magnetic tubes designed to create an extremely effective magnetic circuit. Each row of magnetic tubes is staggered to prevent bridging or choking of the product stream and to maximize magnetic filtration as product flows through the housing. Tramp metal contaminants are attracted to the magnetic tubes. The manually operated cleaning system safely removes tramp metal from the product stream to a disposal area outside the product flow area.

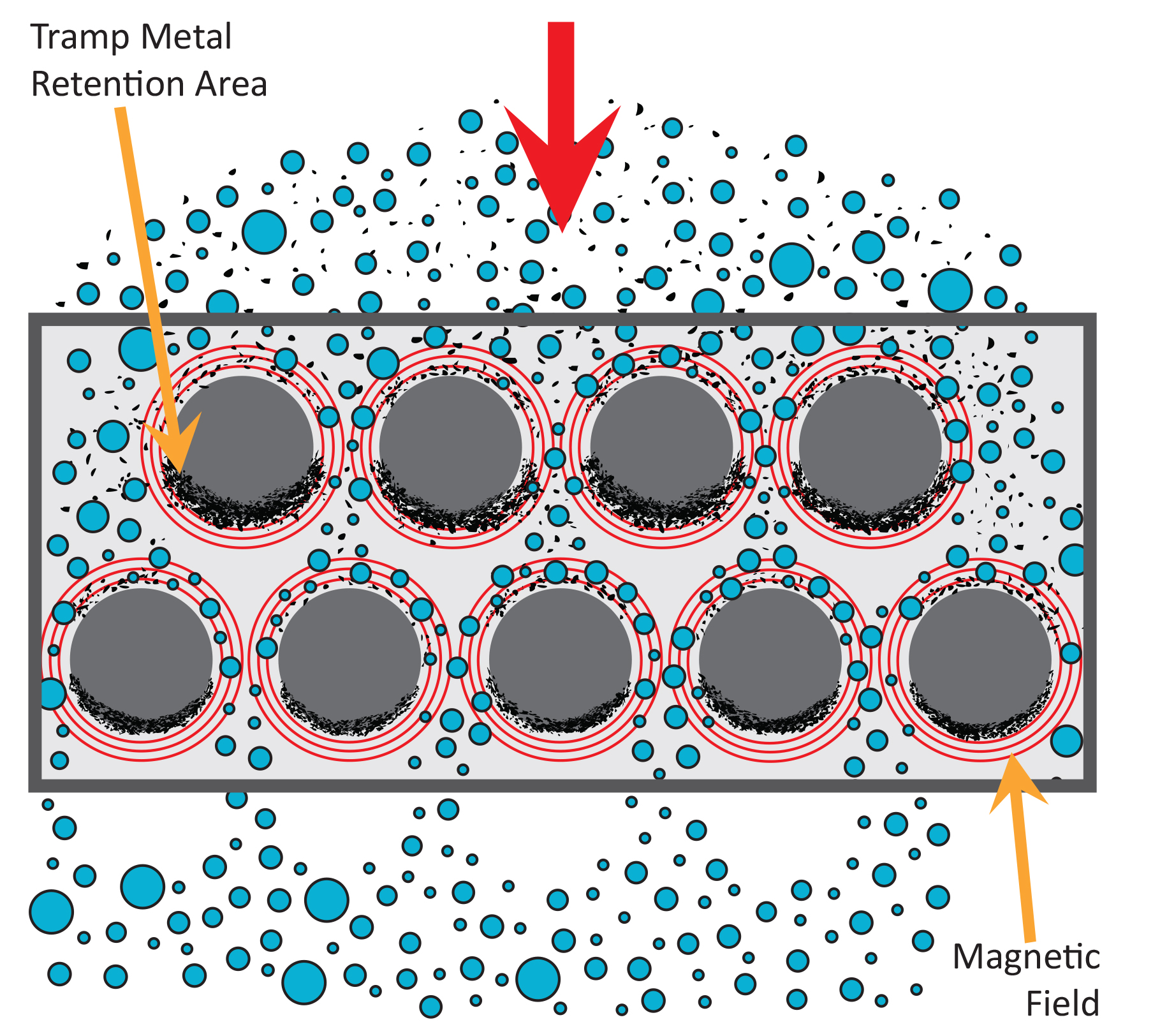

US Customary Units

| ILGDM Model # |

Flow Opening (B) |

Overall Width (C) | Overall Length (Drawer Open) (D) |

Overall Length (Drawer Closed) (E) |

Number of Magnetic Tubes | Approx. Weight | Flow Rate |

| IN | IN | IN | IN | 2 Rows | LBS | FT3/HR | |

| ILGDM 8 | 8 | 19 | 31 | 25.71 | 7 | 120 | 600 |

| ILGDM 10 | 10 | 21 | 35 | 29.71 | 9 | 150 | 1,350 |

| ILGDM 12 | 12 | 23 | 39 | 23.71 | 11 | 180 | 2,400 |

| ILGDM 14 | 14 | 25 | 43 | 37.71 | 13 | 210 | 3,037 |

Metric Units

| ILGDM Model # |

Flow Opening (B) |

Overall Width (C) | Overall Length (Drawer Open) (D) |

Overall Length (Drawer Closed) (E) |

Number of Magnetic Tubes | Approx. Weight | Flow Rate |

| CM | CM | CM | CM | 2 Rows | KG | M3/HR | |

| ILGDM 8 | 20.3 | 48.2 | 79 | 65 | 7 | 54 | 16.99 |

| ILGDM 10 | 25.4 | 53.3 | 89 | 76 | 9 | 68 | 38.23 |

| ILGDM 12 | 30.5 | 58.4 | 99 | 86 | 11 | 81 | 67.96 |

| ILGDM 14 | 35.6 | 63.5 | 109 | 96 | 13 | 95 | 86.00 |

- Custom magnet tube spacing for products with bulk density under 30 PCF

- Multi-tier configuration

- Custom alloy stainless steel construction

- Custom inlet/outlet flange sizing

- Abrasive resistant and non-stick surface treatment

- Inlet and outlet transition adapters sized to customer specifications

- Self-cleaning model available

- Metal detectable plastic components

- Choice of magnet tube material:

- Ceramic 8 magnet material for less severe tramp metal applications

- Rare Earth magnet material for higher operating temperatures

- Hi-G material and Thin Wall designs for specialized applications