|

Beltless Magnetic Conveyors

—————-

|

|

|

|

|

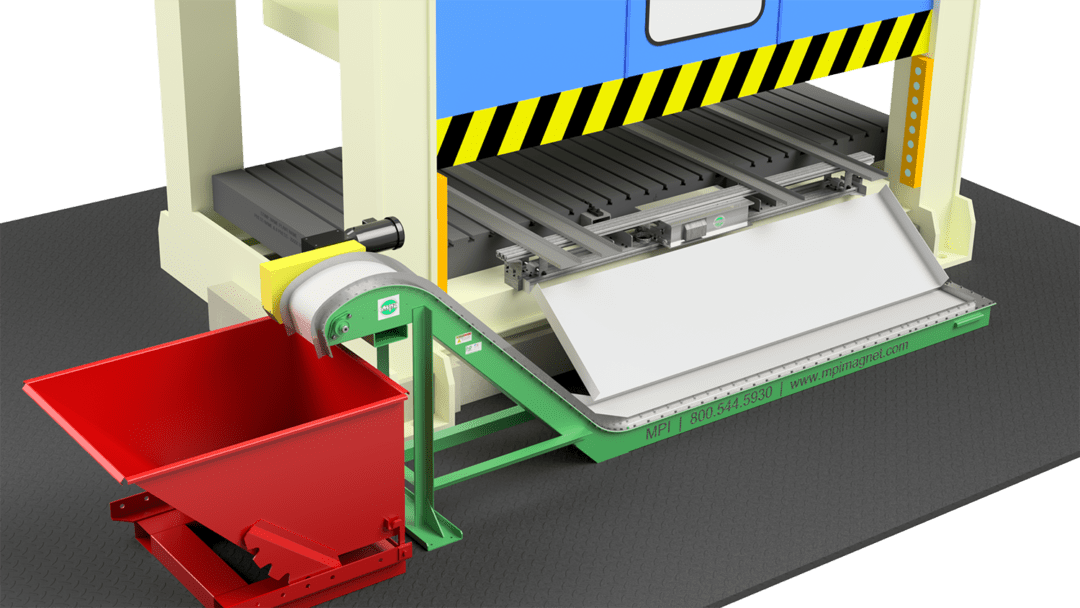

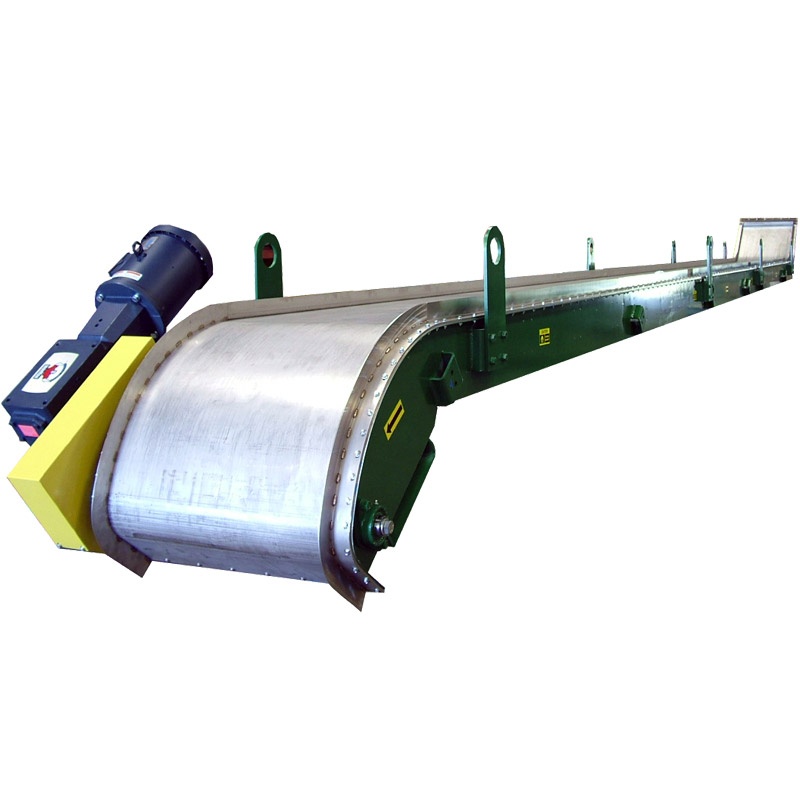

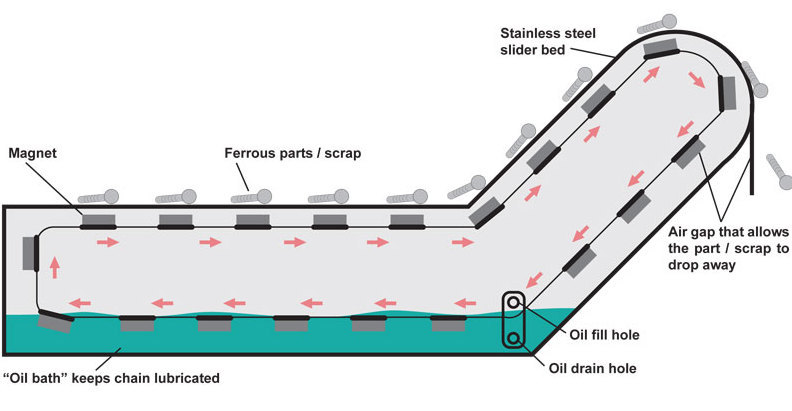

Powerful permanent magnets are conveyed below a nonmagnetic stainless steel slider bed to move and convey ferrous metal objects. The liquid-tight, sealed conveyor housing can be completely submerged in machine reservoir tanks and the internal self-adjusting take-up system eliminates the need for maintenance. No external moving components make the beltless magnetic conveyor the safest way to convey ferrous metal parts and scrap.

| Conveyor Feature | 600 Series | 800 Series | 1200 Series |

| Body Depth | 6.5″ | 8.5″ | 13.875″ |

| Magnetic Capacity | • | •• | ••• |

| Magnet Centers | 5″+ | 6″+ | 8″+ |

| Chain | #2052 | #2062 | #2082 |

| Body Construction | 11 Gauge | 11 Gauge | 7 Gauge |

| Standard In-Feed Length | 30″ or larger | ||

| Self-Adjusting Take-Up | Included | ||

| Slider Bed Thickness | 12 or 7 Gauge depending upon width | ||

| Slider Bed Width | 6″ to 24″ | ||

| Angle of Incline | 0 to 90° (15° increments) | ||

| Speed | 45 FPM | ||

| Magnet Material | Ceramic (rare earth, as required) | ||

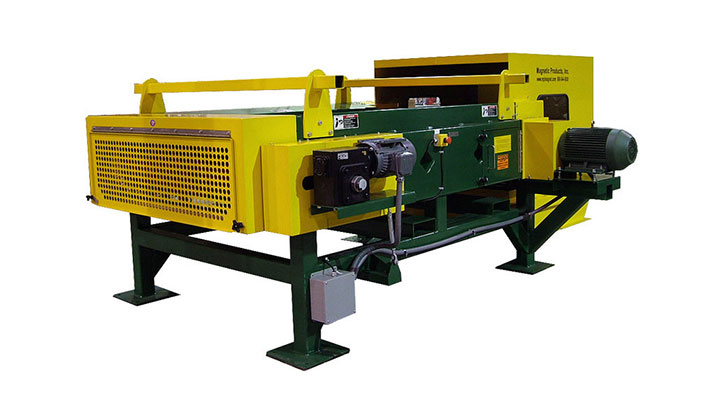

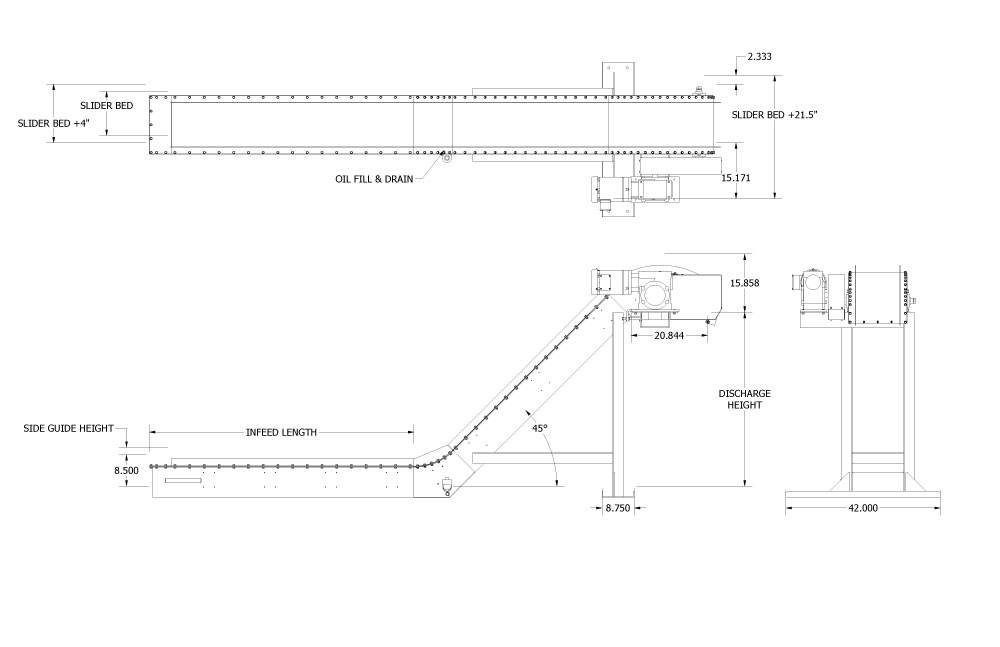

800 Series Dogleg Beltless Magnetic Conveyor

- BLM Series:

- MPI offers three series of magnetic conveyors. Each larger series has a larger body to accommodate larger magnetic cartridges and heavier duty internal chain designed to handle more difficult scrap or higher scrap rate capacities. MPI will help you select the correct duty for your application.

- 600 Series – 6.5″ body depth

- 800 Series – 8.5″ body depth

- 1200 Series – 13.875″ body depth

- MPI offers three series of magnetic conveyors. Each larger series has a larger body to accommodate larger magnetic cartridges and heavier duty internal chain designed to handle more difficult scrap or higher scrap rate capacities. MPI will help you select the correct duty for your application.

- Shape Configuration:

- Horizontal straight

- Incline straight nose over

- Dogleg horizontal/continuous radius discharge

- Dogleg nose over

- Incline straight horizontal/continuous radius discharge

- Discharge Design:

- Horizontal (standard)

- Nose over – recommended or small scrap and compact designs

- Continuous radius – recommended for smooth scrap transfer of long pieces

- Infeed Length:

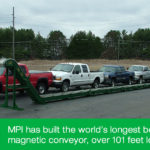

- Minimum infeed length is 30″ to as long as required for customer application

- Angle of Incline:

- 15°

- 30°

- 45°

- 60°

- 75°

- 90°

- Custom

- Discharge Length: The minimum discharge length depends on the discharge design selected. The discharge lengths can be made as long as required for the application.

- Minimum length for nose over-discharge design is body width, the shortest design available

- Minimum length for horizontal discharge design is 22″

- Minimum length for continuous radius discharge design depends on the angle of incline, at least 22″

- Infeed Height: Floor installation is standard. This will result in the infeed height being the body depth specified by the series selected. Legs can be added for raised infeed heights.

- Body depth (standard)

- As specified for the application (legs added)

- Discharge Height:

- No standard – as specified for the application

- Overall Length:

- Calculated based on configured dimensions and options specified above

- Slider Bed Width: Minimum widths are based on series selected. Standard widths are available in increments of 2″ from the minimum to a maximum of 24”. Overall body width of the conveyor is the slider bed width plus 4″.

- 600 series – minimum 6″

- 800 series – minimum 8″

- 1200 series – minimum 12″

- Special – compact design where overall body width of the conveyor is the slider bed width plus 2″

- Slider Bed Material:

- Under 18″ wide – 12 gauge stainless (standard)

- 18″ wide and larger – 7 gauge stainless (standard)

- 7 gauge manganese impact plate for specified length

- 7 gauge manganese impact plate through infeed

- 7 gauge manganese impact plate whole length

- 16 gauge laminated rigidized material on top of standard slider bed to reduce part friction

- 7 gauge manganese impact plate dimpled to simulate rigidized material

- Magnet Material: Standard magnets are ceramic and will work for most applications. Testing will determine if rare earth magnets are required to achieve required rate.

- Ceramic (standard)

- Ceramic with REN rare earth sweepers to break potential surges

- High capacity REN rare earth with stainless steel body to reduce drag

- Magnet Centers: Magnet centers are based on the maximum part length. For proper function of BLM the general rule is the centers will be 1.5 times the parts/scrap maximum length.

- 600 series – increments of 5″ centers

- 800 series – increments of 6″ centers

- 1200 series – increments of 8″ centers

- Side Guides:

- 2″ tall, 90° from slider bed (standard)

- Custom

- Zero radius guides for thin conveyed material

- Drive Package:

- US Manufactured Baldor TEFC (standard)

- Customer specified

- Drive Package Location:

- Offset drive (standard)

- Underhead chain drive

- Overhead chain drive

- Motor Location (looking in direction of product travel):

- Right (standard)

- Left

- Power Input:

- 230/460/3 Phase / 60 Hz (standard)

- 115 /230 1 Phase

- 575 / 3 Phase

- Conveyor Speed:

- Gear reducer for 45 FPM constant speed (standard)

- Customer speed as specified based on testing

- Paint:

- MPI green (standard)

- MPI light gray

- Customer specified

- Oil Fill and Drain Location:

- Located on the same side as the drive package (standard)

- Extended oil fill options available for submerged tank applications

- Custom

- Support Legs:

- Fixed position (standard)

- Adjustable position

- Infeed Casters:

- Not included (standard)

- “V” wheel

- 5″ rigid

- 5″ rigid with brake

- 5″ swivel

- 5″ swivel locking with brake

- Discharge Casters:

- Not included (standard)

- “V” wheel

- 5″ rigid

- 5″ rigid with brake

- 5″ swivel

- 5″ swivel locking with brake (recommended)

- Controls:

- Not included (standard)

- Included as specified

- Other Options Include:

- Submerged tank design for filtration or heat treat applications

- Smoke covers for containing smoke generated from hot parts

- Body inspection doors

- Lanes for transferring different parts on the same conveyor or keeping parts and scrap separate

- Coolant collection (or oil) discharge port on infeed

- Liquid-tight side guides to contain oil