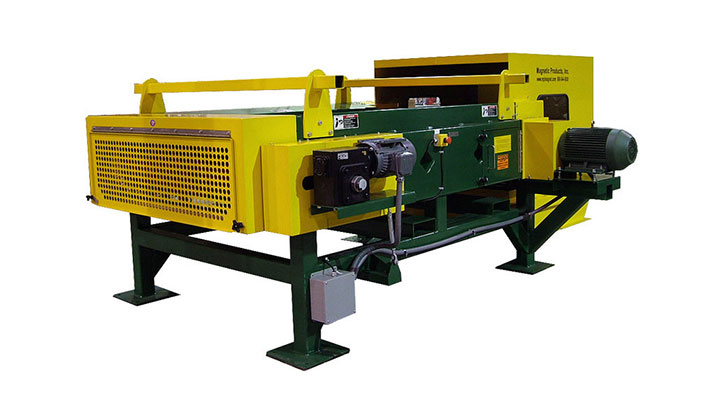

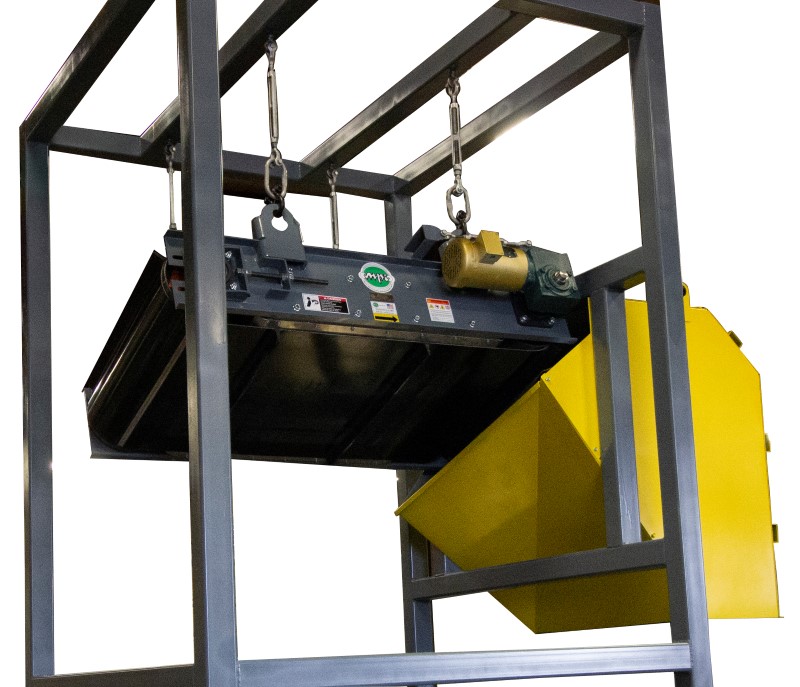

Self-Clean Suspended Permanent Magnets

- Extra-wide belt helps prevent tramp metal damage under the belt, extending belt and component life

- Crowned pulleys for accurate belt tracking

- Optional bucking magnet design increases reach out of the magnetic field by 25%

- 1 HP or 2 HP drive motor

- Speed reducer

- Permanent Ceramic 8 magnet material enclosed in stainless steel

- Adjustable belt take-ups

- A rugged, welded steel framework

- 4 integral frame suspension mounting eyelets

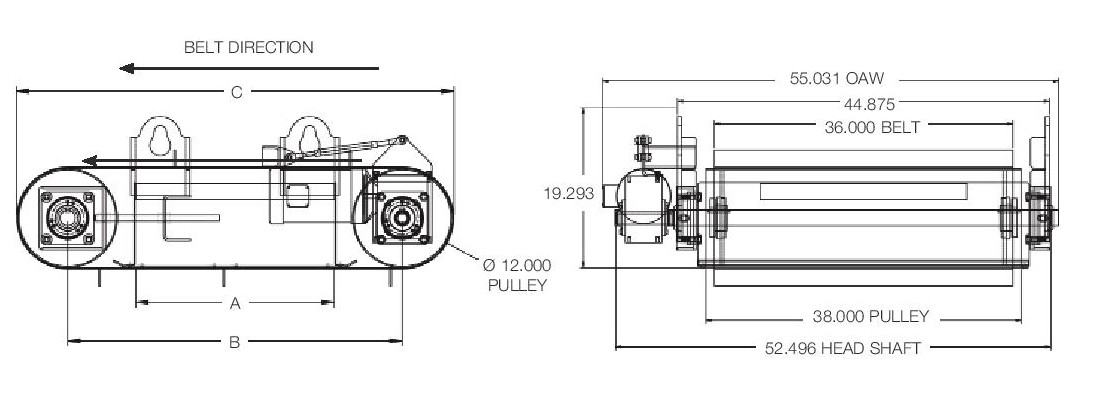

MPI’s Self-Clean Suspended Permanent Magnet includes a conveyor belt moving around the magnet to automatically remove the collected tramp metal from the magnet’s face. The Self-Clean Suspended Permanent Magnet separators feature rubber conveyor belts, adjustable take-ups, rugged steel channel frame and a shaft mounted speed reducer with a direct-drive motor.

US Customary Units

| Cross Belt Model # | Magnet Length (A) | Center-to-Center of Pulleys (B) | Frame Length (C) | Motor Horsepower | Approx. Weight |

| IN2 | IN | IN | LBS | ||

| CBS-124 | 24 | 40 | 53 | 1 | 1678 |

| CBS-130 | 30 | 46 | 59 | 1 | 2147 |

| CBS-136 | 36 | 52 | 65 | 1 | 2726 |

| CBS-142 | 42 | 58 | 71 | 1 | 3462 |

| CBS-148 | 48 | 64 | 77 | 1 | 4397 |

Metric Units

| Cross Belt Model # | Magnet Length (A) | Center-to-Center of Pulleys (B) | Frame Length (C) | Motor Horsepower | Approx. Weight |

| CM2 | CM | CM | KG | ||

| CBS-124 | 61 | 103 | 135 | 1 | 762 |

| CBS-130 | 76 | 118 | 150 | 1 | 974 |

| CBS-136 | 91 | 133 | 165 | 1 | 1237 |

| CBS-142 | 107 | 148 | 180 | 1 | 1570 |

| CBS-148 | 122 | 166 | 196 | 1 | 1994 |

- Dust enclosures

- Explosion-proof motors

- Special belts

- Metal clad

- Abrasion resistant

- Cleated (vulcanized rubber or stainless steel)

- High temperature

- Zero-speed switches

- Foundry application packages

- Suspension turnbuckles

- Tramp iron chute work

- Custom drive system configurations

- Ceramic, Rare Earth and exclusive Hi-G hybrid designs available

- Optional motion sensor