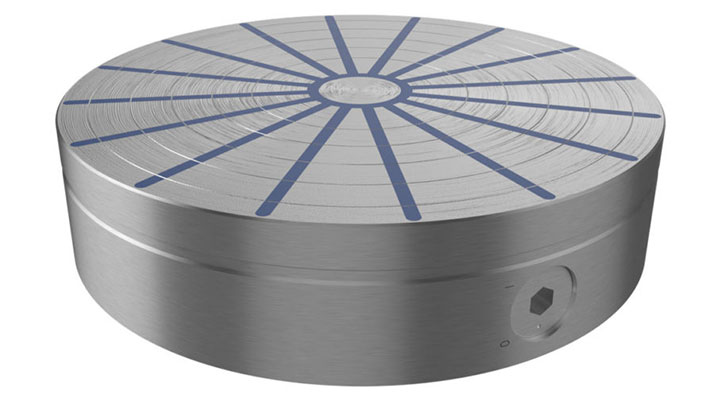

- Permanent ceramic 8 magnet will not demagnetize, create heat or require electricity to operate

- Stainless steel enclosed magnet

- Economical solution for equipment protection

- Includes four (4) eye bolts for suspension

- Optional bucking magnet design increases reachout of magnetic field by 25%

- Quick-clean stripper removes metal from working surface when pulled towards operator

- Ceramic, Rare Earth and exclusive Hi-G hybrid designs available

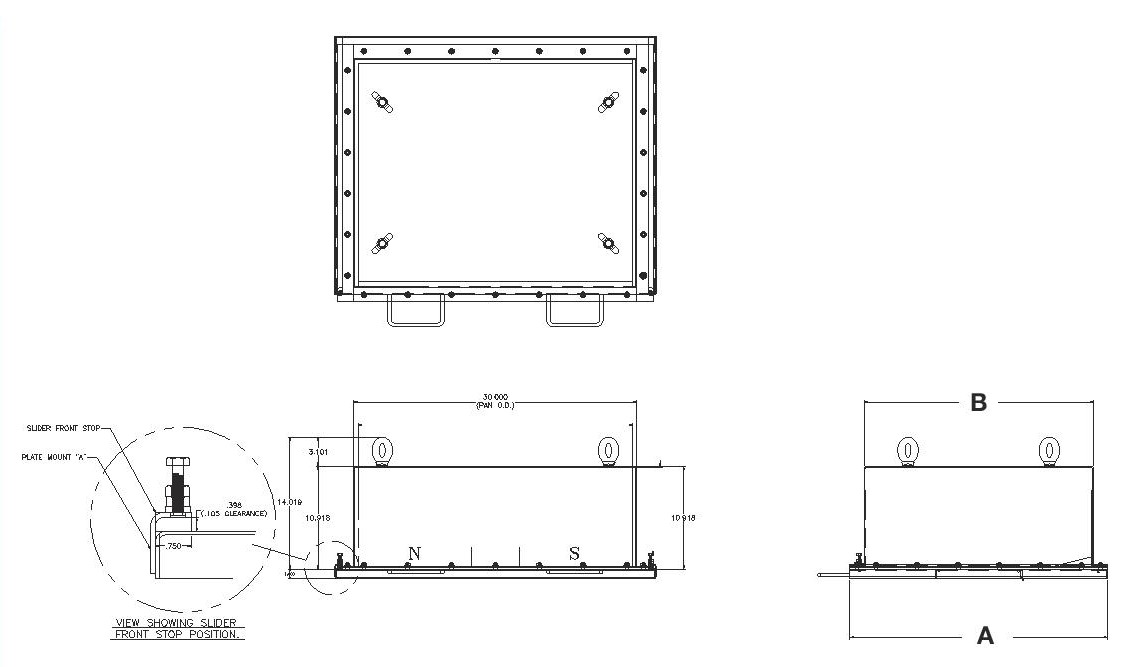

MPI’s Quick-Clean Suspended Permanent Magnets consist of a large plate magnet suspended over the conveyed product stream. The Quick-Clean Suspended Permanent Magnets should be suspended approximately 5” – 8” above the product stream for optimum tramp metal removal (8”-10” with bucking option).

The magnet should be located in an area that has easy access to allow for proper cleaning. Also, the magnet should operate in an area of the belt where no integral parts of the conveyor can become magnetized, such as idler rollers or belting support plates, as this may cause excessive wear on the conveyor system. To clean the magnet, simply grab the handle on the quick clean stripper and pull towards you until it hits stop. After all the metal has fallen from the stripper, slide the stripper face back into place.

US Customary Units

| Receiving Belt Magnet Model # |

Belt Width (A) | Magnet Width (B) | Approximate Weight |

| IN | IN | LBS | |

| RBM-18 | 24 | 18 | 950 |

| RBM-24 | 30 | 24 | 1300 |

| RBM-30 | 36 | 30 | 1600 |

| RBM-42 | 42 | 36 | 1900 |

| RBM-48 | 48 | 42 | 2300 |

Metric Units

| Receiving Belt Magnet Model # |

Belt Width (A) | Magnet Width (B) | Approximate Weight |

| CM | CM | KG | |

| RBM-18 | 61 | 46 | 432 |

| RBM-24 | 76 | 61 | 591 |

| RBM-30 | 91 | 76 | 727 |

| RBM-42 | 107 | 91 | 864 |

| RBM-48 | 122 | 107 | 1046 |

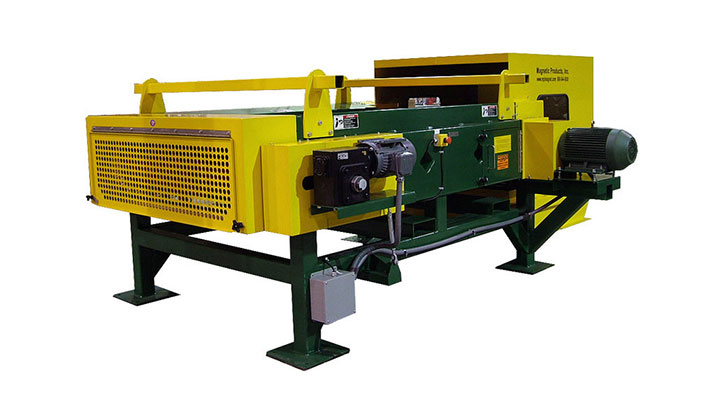

- Self-cleaning models

- Custom support frames

- Heavy-duty sanitary design support frame

- “Bucking Magnet” configuration for enhanced strength and reach out, resulting in a performance increase of approximately 25%

- Ceramic, Rare Earth and exclusive Hi-G hybrid designs available