Protecting and Moving the World Through Innovation

Protecting and Moving the World Through Innovation

Magnet Audit Services

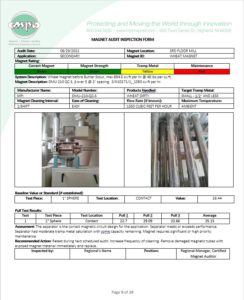

MPI Magnet Audit Sample Audit Page

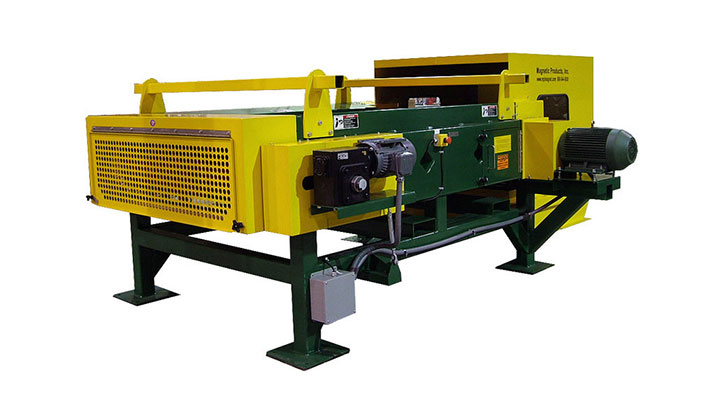

We test every magnet in your facility, no matter the age, condition, application, or brand.

We understand the importance of magnetic separators working at peak performance. Which is why we have been conducting magnet certification audits since 1982 as a service to our customers. These audits support their efforts to develop and maintain an effective metal control program.

When you request an expert audit, one of our certified auditors will travel to your facility, conduct an inspection and a strength test on each magnet, and assess the overall metal control strategy. Upon completion of the audit, we generate a comprehensive report that explains our findings and provides recommendations for action to be taken if any is needed. These reports may also serve as support to corporate quality professionals or regulatory audits. In 2016, we launched our Certified Magnet Auditor Program to further standardize the quality and consistency of the reports, while also expanding our network of Certified Magnet Auditors to better support our customers.

All MPI Certified Magnet Auditors use NIST certified digital pull test scales, NIST certified gauss meters, and all test spheres are certified carbon steel ball bearings that have been welded to a stainless-steel ring and coated in zinc to prevent corrosion.

The Benefits of Magnet Certification Audits from Magnetic Products, Inc:

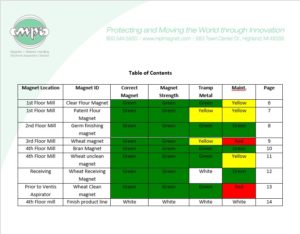

MPI Magnet Audit Sample Audit Page TOC

- Easy to read audit results with photos of each magnetic separator and a color-coded rating system that helps you identify the separator and areas for improvement.

- Exclusive rating system using four (4) criteria to ensure your separators are operating at peak performance.

- Comprehensive picture of a facility’s metal control system and proof of HACCP compliance with required documentation.

- Consistent reporting from certified auditors enables year-over-year trend analysis and maintenance forecasting.

- Conducted by HACCP Certified MPI Regional Managers who are familiar with the quality programs used by each customer

- NIST certified Pull Test Kit replaces the need for a certified scale, as well as the time, resources and training need to conduct audits internally

MPI Rating System

Each magnet is assessed based on four criteria. Each criterion is rated on a color scale from green to red based on the results found by the Certified Magnet Auditor. The criteria and color scales are:

| Correct Magnet: This rating is based on whether the separator is the correct type of separator as required by the application. | |

| Green | Correct magnet, no action required |

| Yellow | Consideration for improvement as noted |

| Red | Replace separator as recommended |

| Magnet Strength: This ensures that the magnet has the required strength for the application. | |

| Green | Magnet is testing at or above baseline values |

| Yellow | Magnet strength has decreased but within less than a 20% range |

| Red | Magnet is testing greater than 20% below baseline value |

| Tramp Metal: This rating is based on the amount of tramp metal saturation the separator has at the time it was tested. | |

| White | Magnet was cleaned before the auditor inspected the magnet |

| Green | Separator had minimal tramp metal saturation |

| Yellow | Separator had moderate tramp metal saturation |

| Red | Separator was fully saturated with tramp metal |

| Maintenance: This rating is based on the separators requirement for maintenance. | |

| Green | No maintenance required |

| Yellow | Maintenance required as noted |

| Red | Immediate action required as noted |