METAL FORMING MANUFACTURERS

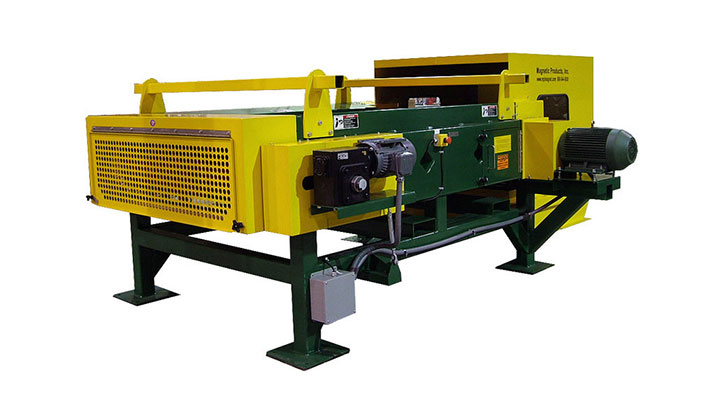

MPI helps you reduce the trauma of production delays by providing the most reliable parts

handling and scrap removal equipment

METAL FORMING MANUFACTURERS

MPI helps you reduce the trauma of production delays by providing the most reliable parts handling and scrap removal equipment

WHY CHOOSE MPI?

- We understand that you shouldn't have to shut down your production line to repair support equipment.

- We know quality – we have sold thousands of systems that have been operating reliably for over 20 years.

- We care – we have 24/7 support to address your or any of your shifts' needs.

- MPI Customer Bill of Rights — read them here.

Schedule an Appointment

WHY CHOOSE MPI?

- We understand that you shouldn't have to shut down your production line to repair support equipment.

- We know quality – we have sold thousands of systems that have been operating reliably for over 20 years.

- We care – we have 24/7 support to address your or any of your shifts' needs.

- MPI Customer Bill of Rights — read them here.

Schedule an Appointment

![]()

KEEP YOUR INVESTMENT RUNNING AT PEAK PERFORMANCE

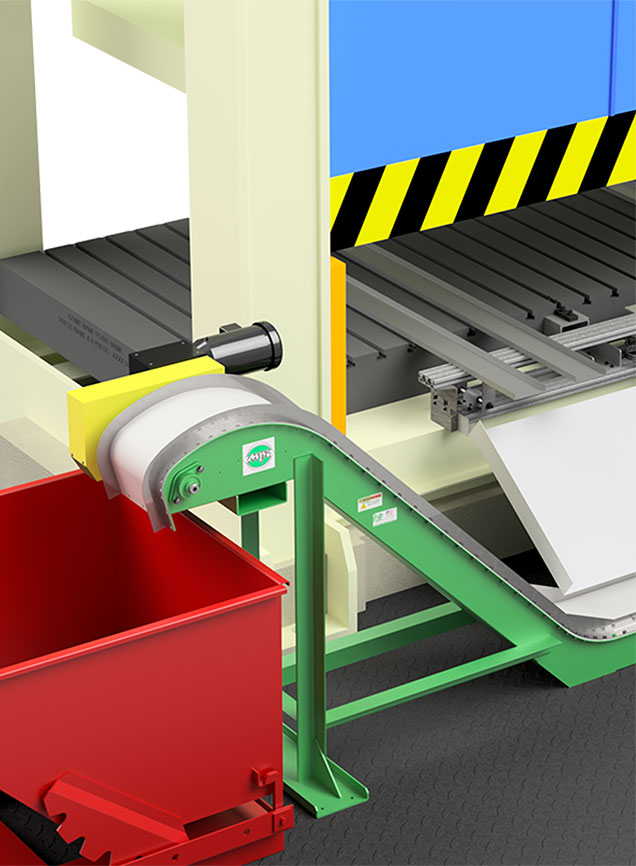

Unscheduled repairs can quickly become a traumatic event that disrupts production and can cost more than $1,000 per hour in idle time. Shipments can get delayed. Customers can become disappointed. Reputations can suffer.

MPI does not want this to happen to you! Download our paper below. It addresses the four most common failures in shaker systems and how to avoid them. We also weigh the advantages of electric shaker systems over pneumatic technology. These guidelines can help you make the business case for updating scrap clearing systems from pneumatic or conveyor belt technology to the reliable and cost-effective electric shaker and central scrap systems.

Download White Paper

![]()

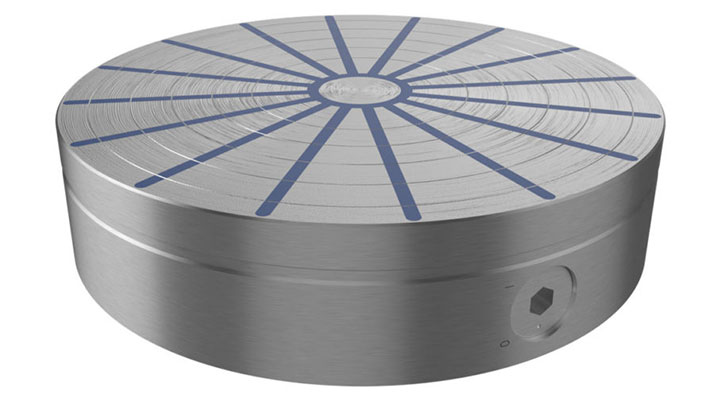

METAL CONTROL SYSTEM AUDITS

MPI believes that to accomplish total confidence in your metal control plan you must base it on education and regular Metal Control System audits.

MPI metal control systems audits are a comprehensive picture of a facility’s metal control system. Part of your audit will include an education training seminar for your employees to learn about your specific metal control equipment and how to maintain it. When you contact us to schedule an audit we will:

1. Develop audit plan: To have a successful audit, we need to review your current quality requirements to ensure they are followed during the audit.

2. Education seminar: An optional educational seminar is designed to help your team understand metal control technology basics, maintenance and proper test methods.

3. Conduct the audit: Walking your plant together we will inspect the currently installed equipment and test each system.

4. Written report: Following the audit, a written report will be submitted with the results of the audit.

5. Prioritize and execute: Based on your prioritization we will help you develop the business case and execute the plan together.

6. Peace of mind: You enjoy the peace of mind that you have installed metal control equipment that will deliver years of reliable service.

Schedule an Audit or Assessment

Popular Metal Forming Industry Products